KMC Controls MEP-4800 Series User Manual

Installation guide, Direct-coupled controlset, Actuators (40/80 in-lb.)

MEP-4000/4800 Series

1

Installation Guide

Installation Guide

Direct-Coupled ControlSet

®

Actuators (40/80 in-lb.)

MEP-4000/4800 Series

Direction, Feedback, and Auto-Mapping (MEP-4xx2)

Maintenance 4

More Information 4

Mounting

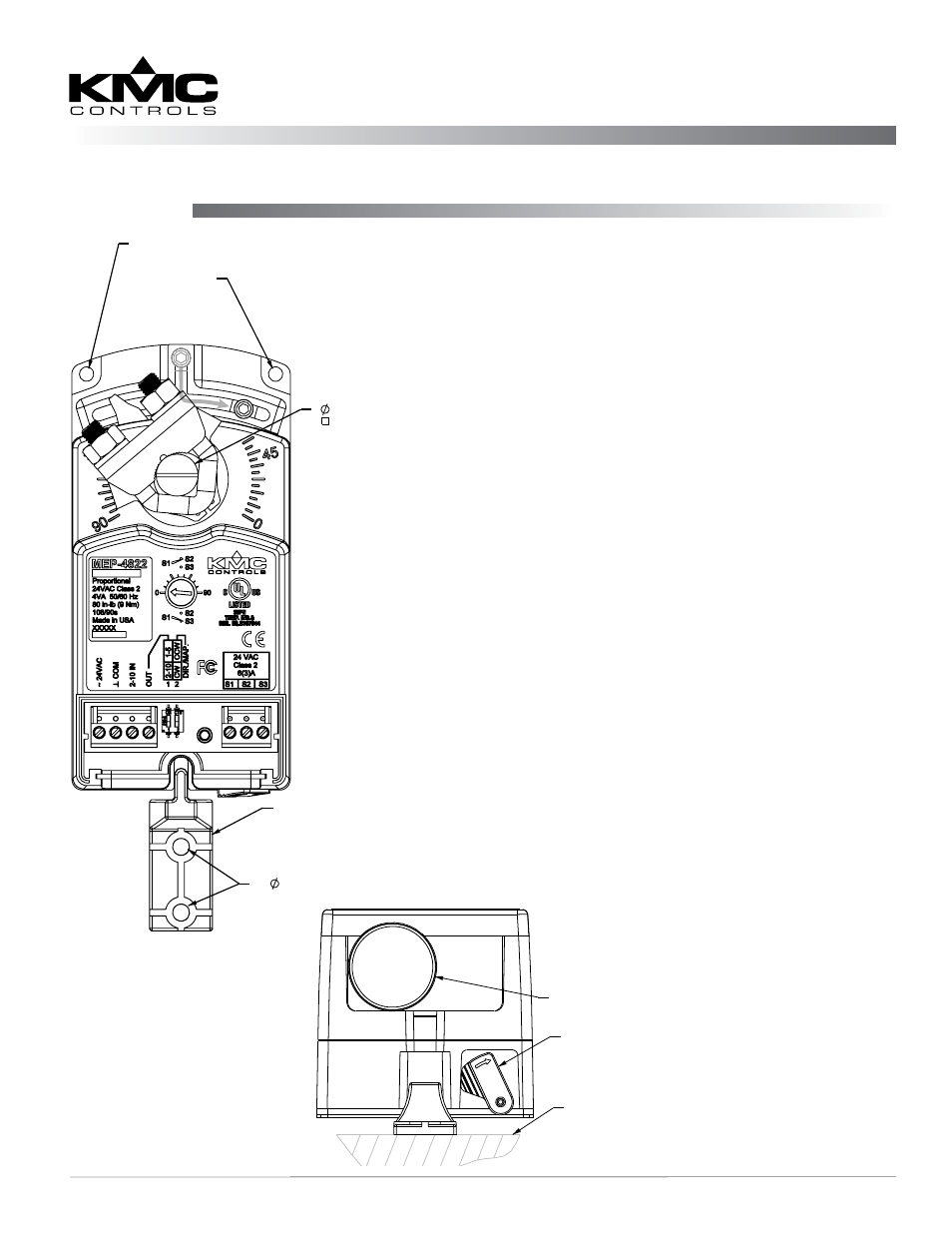

Illustration 1—Overview

(Direct-Coupled Mounting)

1. Ensure the damper can move freely through its

entire range of motion, and fix any binding before

installing the actuator. Turn the damper blade to

its fully closed position.

2. Press (to the right) and hold the gear

disengagement lever (see Illustration 1), rotate the

actuator to the fully closed position, and release

the lever.

NOTE: Depending on the damper-seal design,

backing the actuator off its stop

approximately 5° may provide tight

damper shut-off.

3. Align the actuator and slide it onto the shaft.

4. Leaving a gap between the actuator and

mounting surface to prevent any binding, finger-

tighten the nuts on the V-bolt.

5. Insert the non-rotation bracket (HMO-4002

supplied or HMO-4001 “T” bracket available

separately) into the slot at the base of the actuator.

(See Illustration 1).

6. Secure the non-rotation bracket with two (2) #8 or

#10 self-tapping screws.

7. Evenly tighten the V-bolt nuts 30–35 in-lb. on

MEP-4000s or 60–70 in-lb. on MEP-4800s.

8. If desired, use a 7/64-inch hex key wrench to

loosen and position the end-stop screw.

NOTE: The two holes at the top of the actuator

are NOT for use in direct-coupled

applications. They are for remote

mounting, such as with the optional HLO-

4001 Crank Arm Kit (

ADJUSTABLE

END STOP

THESE HOLES ARE FOR USE IN

REMOTE MOUNTING SITUATIONS—

DO NOT USE IN DIRECT COUPLED

APPLICATIONS

0.200 (5mm)

NON-ROTATION BRACKET

(HMO-4002)

1/4" to 5/8" (6 to 16mm)

1/4" to 7/16" (6 to 11mm)

(2)

GEAR

DISENGAGEMENT

LEVER

MOUNTING

SURFACE

REMOVEABLE CONDUIT FITTING

WITH 1/2" NPS THREADED HOLE