Linkage to mep–1200 series actuator, Linkage to mep–5000 series actuator, Maintenance – KMC Controls HPO–5213 User Manual

Page 2

HPO–5211/5212/5213

2

Installation Guide

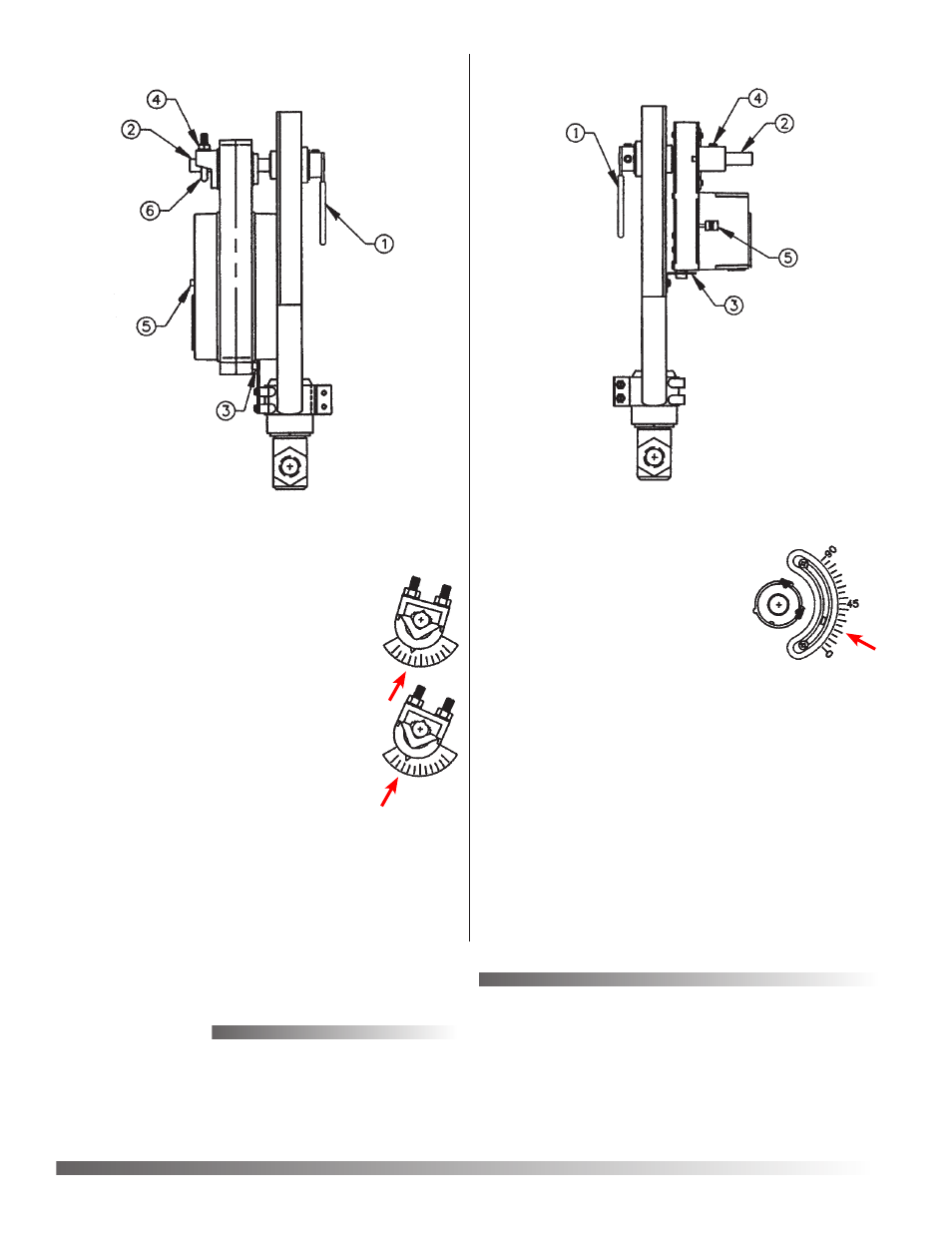

1. Rotate valve linkage lever (1) so that valve stem

(and connecting rod) is in fully

down position.

2. Depress actuators disengagement

button (5) and manually position

actuator pointer between the 20°

and 30° marks.

3. Place actuator over linkage shaft

(2) and non-rotation bracket (3).

4. Tighten 2 setscrews (4) on actuator output hub

while holding linkage lever in position to ensure

valve stem stays fully down.

NOTE: Valve is fully stroked

in each direction with

less than 90° rotation of actuator.

1. Rotate valve linkage lever (1) so that valve stem

(and connecting rod) is in fully down position.

2. Depress disengagement button (5) on actuator and

manually set pointer to the following

position:

For 1/2" through 1-1/4" valves with

HPO–5212 linkage, set pointer at

third mark from full clockwise.

For 1-1/2" through 2" valves with

HPO–5213 linkage, set pointer at

second mark from full clockwise.

3. Place actuator over linkage shaft (2)

and non-rotation pin (3) until cover on

actuator rests against cover on linkage.

4. Finger-tighten 2 coupler nuts (4) until

U-bolt (6) contacts linkage shaft (2).

5. Hold the linkage lever (1) in position to ensure

valve stem stays fully down while evenly torquing

2 coupler nuts (4) to 110–120 in-lbs. Also be sure

actuator cover is held against linkage while

tightening coupler nuts.

NOTE: Valve is fully stroked in each direction with

less than 90° rotation of actuator.

•

•

© 2006 KMC Controls, Inc.

732-019-07B

KMC Controls, Inc.

19476 Industrial Drive

New Paris, IN 46553

574.831.5250

www.kmccontrols.com

Maintenance

No routine maintenance is required. Each compo-

nent is designed for dependable, long-term reliabil-

ity, and performance. Careful installation will also

ensure long-term reliability and performance.

Linkage to MEP–1200 Series Actuator

Linkage to MEP–5000 Series Actuator