Elecraft K1 User Manual

Page 21

20

E

LECRAFT

Open the bag labeled MISCELLANEOUS and empty the

contents into a shallow box or pan. This will prevent loss of any of

the small hardware while allowing you to locate items as needed.

i

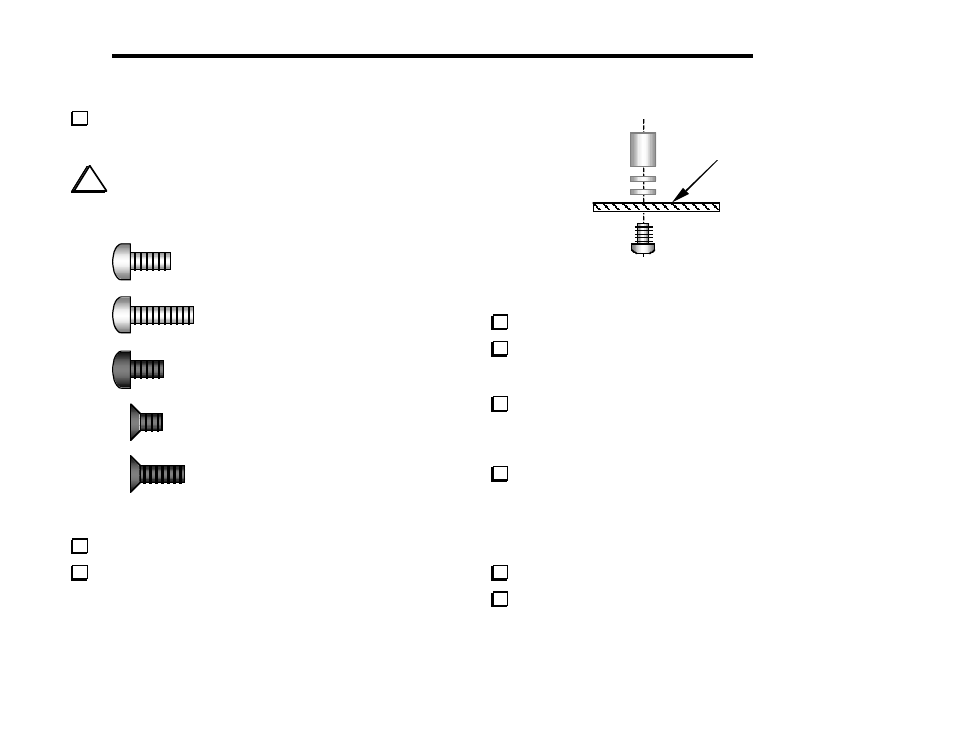

Five sizes of 4-40 screws are used. All are black anodized

except the 1/4" and 3/8" pan heads (see Figure 5-5). The length of

flat-head screw is measured from the top of the head.

Flat-head, 3/16” (4.8 mm)

Pan-head, 3/16” (4.8 mm)

Flat-head, 5/16” (8 mm)

Pan-head, 3/8” (9.5 mm)

Pan-head, 1/4” (6 mm)

Figure 5-5

Identify all of the 4-40 screws and sort them into groups.

Install a 3/16" (4.8 mm) diameter x 1/4" (6.4 mm) long round

standoff on the top of the board (Figure 5-6). The hole for this

standoff is just below the large hole. Use two #4 split lock washers

and a 1/4" (6 mm) pan-head screw (not black anodized) as shown.

Insert the lock washers between the standoff and PC board.

Top Side

Figure 5-6

Install crystal X1, near C1 and C2 on the bottom of the board.

To the right of X1 you'll find a ground pad for the crystal can.

Use a discarded component lead to make the grounding wire, as

shown in Figure 4-1 (page 13).

Locate LEDs D1 and D2, which are identical in size but have

different-colored bodies. D1 has a clear diffuse body, while D2 has a

yellow tint. Near the point where the leads exit the body, you'll find

a flat side in the plastic, which identifies the cathode lead.

Install D1 (clear diffuse body) on the top side of the board,

with its flat side aligned with the flat side of the component

outline. (This is the side nearest the square pad.) Position D1 about

1/16" (1.5 mm) above the board. You can use the switch-spacing

tool, a toothpick, or short length of insulated hookup wire to

maintain the proper spacing while soldering.

Verify the orientation of D1's flat side, then solder.

Install and solder D2 using the same method.