Elecraft K1 User Manual

Page 15

14

E

LECRAFT

i

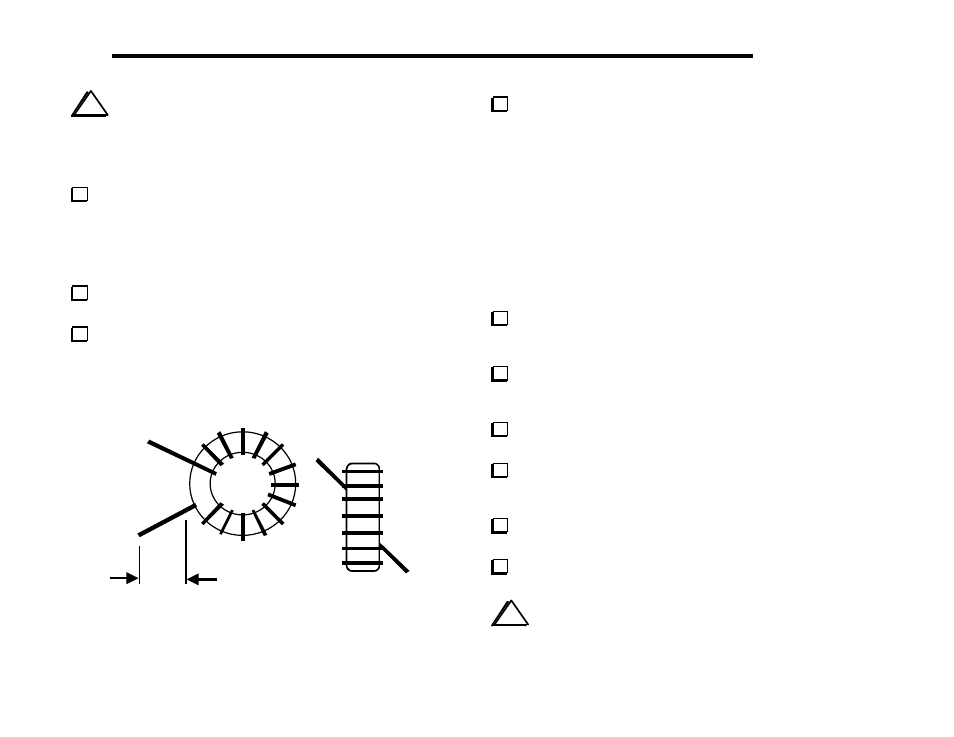

In the following steps you’ll install toroidal inductors L9-

L12 (type T37-6 cores). They must be wound as indicated in the

instructions, or the transceiver will not operate correctly. Use only

the number of turns specified. It is not necessary to attempt to

precisely match the inductances specified in the parts list.

Find the component outline for L9 on the Filter board.

Compare this component outline to Figure 4-3, which shows two

views of a typical toroidal inductor. L9 will be mounted vertically

as shown at the right side of the drawing, with one wire exiting at

the core’s upper left, and the other at the lower right. There are

pads on the PC board in these two locations.

Using the Per-Band Components parts table (Band 1),

determine the number of turns and wire length for L9 and L10.

To wind L9, cut the specified length of #26 red enamel-coated

wire, then "sew" the long end of the wire through the core. Each

pass through the core counts as one turn. The finished winding

should look similar to Figure 4-3, but with the number of turns

indicated in the parts list. Figure 4-3 shows 14 turns.

Remove insulation

Figure 4-3

Verify that the turns of L9 are not bunched together. They

should be evenly spaced, and should occupy about 80-90% of the

core.

Stripping Toroid Leads

The enamel wire supplied with the kit can be heat-stripped. One

way to do this is to place a small amount of solder (a "blob") on the

end of your soldering iron, then insert the wire into the hot solder.

If the iron is hot enough, you should see the insulation vaporize

after 3 to 6 seconds. Another possibility is to burn the insulation

off by heating it with a small butane lighter for a few seconds, then

use fine-grain sandpaper to remove the enamel residue. Avoid

scraping insulation off with a razor blade, as this may nick the wire.

Strip the leads of L9, as explained above. You should remove

the enamel from the leads up to about 1/8" (3 mm) from the core

(Figure 4-3).

Tin L9's leads. The solder should appear clean and shiny. If it

looks dull or is not adhering very well to the bare lead, there is

probably some insulation remaining. Remove it as described above.

Install L9 vertically as shown by its component outline. Pull

the leads taut on the bottom of the board.

Solder the leads of L9. When soldering, make sure that the

solder binds well to the leads. If the lead appears to be an "island" in

a small pool of solder, chances are it is not making good contact.

Wind and install L10 in the same manner as L9, using the

same number of turns. Install L10 vertically, to the right of L9.

Wind and install L11 and L12. Use the Per-Band Components

table (Band 2) to look up the wire length and number of turns.

i

Do not use adhesives or fixatives of any kind to secure L9-

L12 to the PC board. They will be adequately held to the board by

their leads alone.