Discrete plc programming – Rockwell Automation 1336T ControlNet Frn1.02 Rev 1.5 User Manual

Page 39

3–3

Using Scheduled Discrete Data Transfer

Publication 1336 FORCE–5.18 ––March, 1999

Discrete PLC Programming

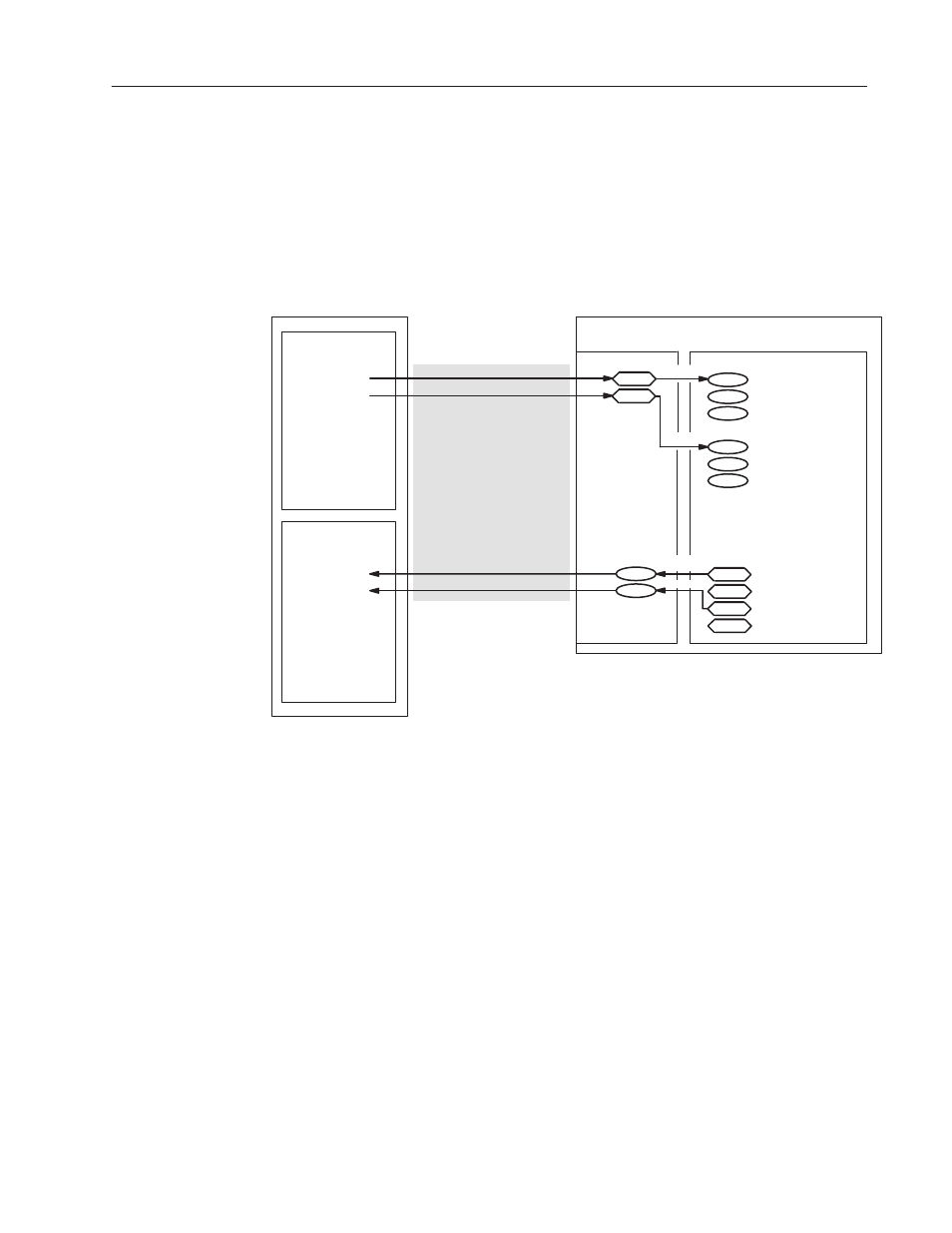

The following figure shows an application where the ControlNet

Adapter Board has been set up for rack 2 and the PLC program is

using the 16-bit words for groups 0 and 1 for data transfer with the

1336 FORCE. You should refer to this figure to help understand the

following description.

162 Ext Torque Ref 1

Output Image Table

Rack 2

0:020 (Group 0)

0:021 (Group 1)

0:022 (Group 2)

0:023 (Group 3)

0:024 (Group 4)

0:025 (Group 5)

0:026 (Group 6)

0:027 (Group 7)

322

323

351

352

PLC

1336

FORCE

ControlNet Adapter Board

367 ChA Logic Cmd In

101 Velocity Ref 1 HI

Input Image Table

Rack 2

I:020 (Group 0)

I:021 (Group 1)

I:022 (Group 2)

I:023 (Group 3)

I:024 (Group 4)

I:025 (Group 5)

I:026 (Group 6)

I:027 (Group 7)

56 Logic Status Low

146 Velocity Feedback

Sources

Sinks

Drive Parameters

Sources

(Link)

(Link)

(Link)

(Link)

Scheduled

Discrete

Data Transfer

In this example, the drive has been configured so that the data

coming into source parameter 322 is linked to parameter 367, ChA

Logic Cmd In. Information linked to the 1336

FORCE using the

16-bit output word for group 0 of rack 2 must be a 16-bit word

where the bits are defined by the description of parameter 367.

Parameter 101, Velocity Ref 1 HI, has been linked to source

parameter 323. The 16-bit output word for group 1 of rack 2 must be

a 16–bit signed integer whose value is within the allowable range of

values in drive units for parameter 101.