Rockwell Automation 150 SMC-Flex User Manual User Manual

Page 121

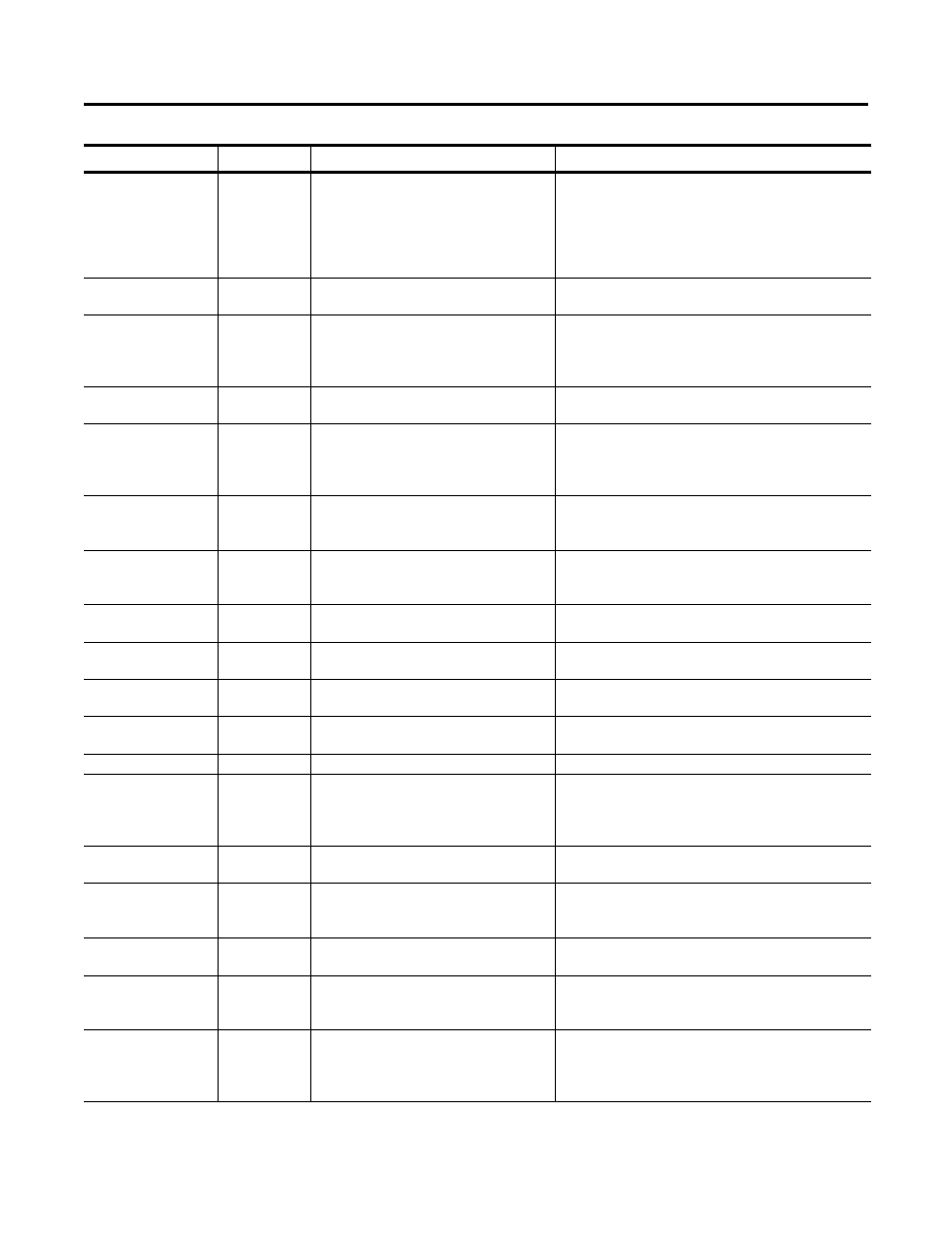

Troubleshooting

9-3

Open Bypass

13, 14, & 15

•

Control voltage is low

•

Inoperable power module bypass

•

Check control voltage power supply

•

Replace power module

•

Check control module TB2…TB4 and TB5…TB7 for

secureness

•

Check Aux 1, 2, 3, 4 configurations are not set to

External Bypass

No Load

16, 17, 18, &

40

•

Loss of load side power wiring

•

Check all load side power connections and motor

windings

Line Unbalance

19

•

Supply unbalance is greater than the

user-programmed value

•

The delay time is too short for the

application

•

Check power system and correct if necessary

•

Extend the delay time to match the application

requirements

Overvoltage

20

•

Supply voltage is greater than user-

programmed value

•

Check power system and correct if necessary

•

Correct the user-programmed value

Undervoltage

21

•

Supply voltage is less than user-

programmed value

•

The delay time is too short for the

application

•

Check power system and correct if necessary

•

Correct the user-programmed value

•

Extend the delay time to match the application

requirements

Overload

22

•

Motor overloaded

•

Overload parameters are not matched

to the motor

•

Check motor overload condition

•

Check programmed values for overload class and

motor FLC

Underload

23

•

Broken motor shaft

•

Broken belts, toolbits, etc.

•

Pump cavitation

•

Repair or replace motor

•

Check machine

•

Check pump system

Jam

24

•

Motor current has exceeded the user

programmed jam level.

•

Correct source of jam

•

Check programmed time value

Stall

25

•

Motor has not reached full speed by

the end of the programmed ramp time

•

Correct source of stall

Phase Reversal

26

•

Incoming supply voltage is not in the

expected ABC sequence

•

Check power wiring

Coms Loss

27, 28, & 29

•

Communication disconnection at the

serial port

•

Check for a communication cable disconnection to

the SMC-Flex controller

Network

30, 31, & 32

•

DPI network loss

•

Reconnect for each DPI connected device

Ground Fault

33

•

Ground fault current level has

exceeded programmed value

•

Check power system and motor; correct if

necessary

•

Check programmed ground fault levels to match

application requirements

Excess Starts/Hr.

34

•

Number of starts in a one hour period

has exceeded the value programmed

•

Wait an appropriate amount of time to restart

•

Turn off the Starts/Hr. feature

Power Loss

➀

(with phase

indication)

35, 36,

& 37

•

Missing supply phase (as indicated)

•

Check for open line (i.e., blown line fuse)

Hall ID

38

•

Incorrect power module has been

installed

•

Check power module and replace

NVS Error

39

•

Data entry error

•

Check user data

•

Replace control module

•

Reset default values

Line Loss

41, 42, 43

•

Line distortion

•

High impedance connection

•

Check supply voltage for capability to start/stop

motor

•

Check for loose connections on line side or motor

side of power wires

Table 9.A SMC Fault Display Explanation (Continued)

Display

Fault Code

Possible Causes

Possible Solutions