Rockwell Automation 20L PowerFlex 700L Frame 1X Liquid-Cooled Adjustable Frequency AC Drive User Manual

Page 42

PowerFlex 700L Frame 1X Drive Installation Instructions – Publication 20L-IN013A-EN-P – June 2009

42

– Speed/Torque Control & Direction Limits

– Speed Reference

– Start & Stop Modes

– Ramp Setup

– Digital and Analog I/O

– Application Set-up (TorqProve, Oil Well Pumps, Positioning/Speed

Profiling)

See

Running an Assisted Start Up on page 43

for details.

Important Information

Power must be applied to the drive when viewing or changing parameters.

Previous programming may affect the drive status and operation when

power is applied. If the I/O Cassette has been changed, a Reset Defaults

operation must be performed.

Torque Proving applications can use the Assisted Start Up to tune the motor.

However, it is recommended that the motor be disconnected from the hoist/

crane equipment during the routine. If this is not possible, refer to the

TorqProve Manual Start Up procedure in the PowerFlex 700 Series B User

Manual (publication 20B-UM002).

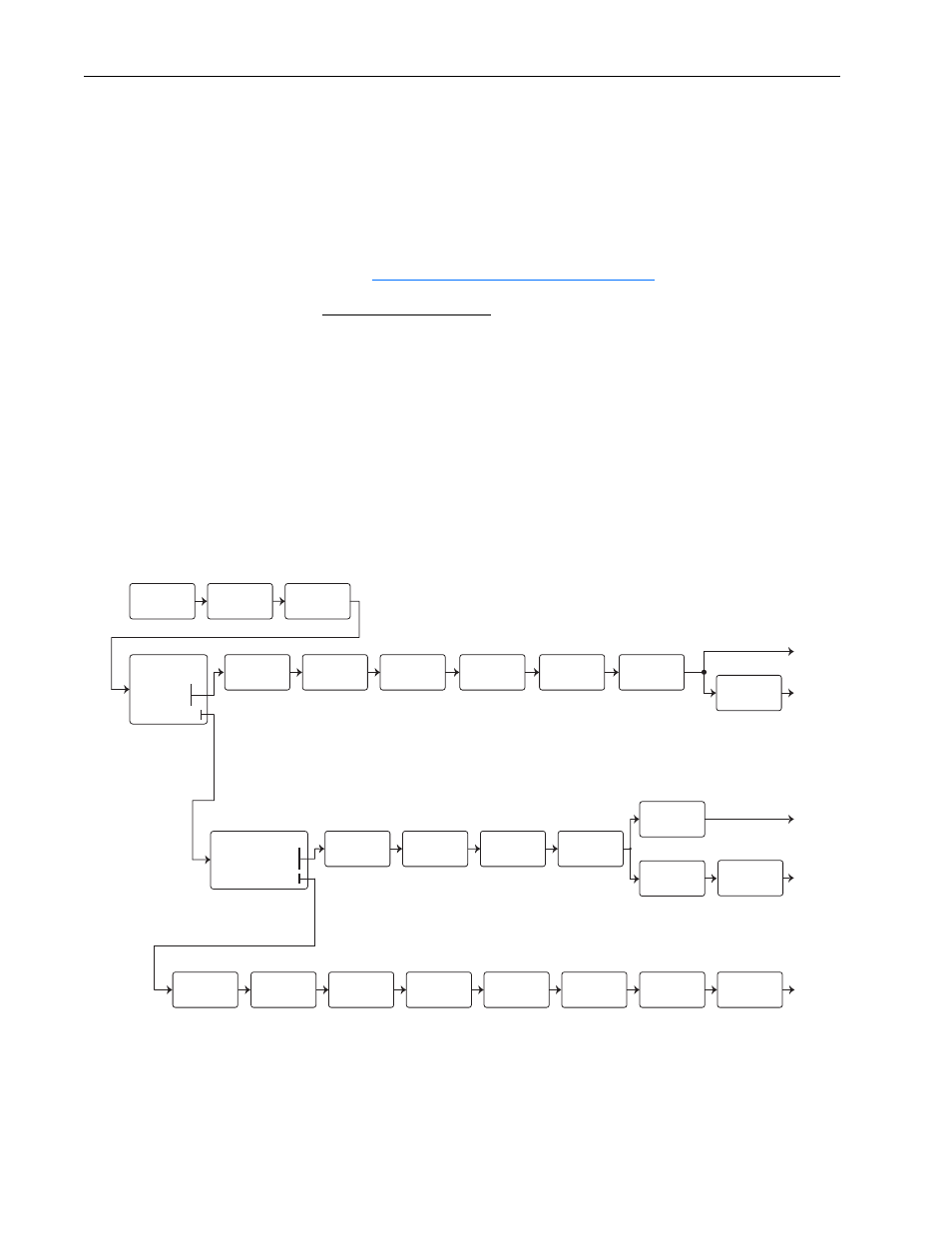

Figure 18

Start Up Menu

Configures

Motor Control

Method

Motor Control

Select

Enter Motor NP

Data, Stop Mode,

Accel/Decel

Ramp Times

Motor Data &

Ramp Times

Optimize Torque

and

Verify Direction

Motor

Tests

(1)

Set Min/Max

Speed and

Direction Control

Speed

Limits

Configure

Source, Value

and Scale for

Speed References

Speed/Torque

Control

Start/Stop/

I/O

Configure

Control Method

(2 Wire/3 Wire),

I/O, Digital I/O

& Analog Outputs

Configure for a

Specific Application

such as; Auto Restart,

Flying Start, etc.

Basic

Start-Up

Continue

Start Over

Intro

Configures

Motor Control

Method

Motor Control

Select

Enter Motor NP

Data, Stop Mode,

Accel/Decel

Ramp Times

Motor Data &

Ramp Times

Optimize Torque

and

Verify Direction

Motor

Tests

Set Min/Max

Speed and

Direction Control

Speed

Limits

Configure

Source, Value

and Scale for

Speed References

Speed/Torque

Control

Done /

Exit

Pos/Spd

Profile

Pos/Spd Profile

Done /

Exit

Torque

Proving

Torque Proving

Detailed

Application

Selection:

1. SMART

2. Basic

3. Detailed

4. Application

Enter Motor NP

Data, Stop Mode,

Accel/Decel

Ramp Times

Enter Pump

Data

(1)

During Motor Tests and tuning procedures, the drive may modify certain parameter values for proper Start Up operation. These values are then reset to their original values when

Start Up is complete. The affected Parameters are 053, 080, 276, 278, and 361…366. If power is removed from the drive during the tests without aborting the auto-tune procedure,

these parameters may not be reset to their original value. If this situation occurs, reset the drive to factory defaults and repeat the Start Up procedure.

Motor Data &

Ramp Times

Well Pump

Type

Optimize Torque

and

Verify Direction

Motor

Tests

Pump

Data

Start/Stop/

I/O

Configure

Control Method

(2 Wire/3 Wire),

I/O, Digital I/O

& Analog Outputs

Configure

Source, Value

and Scale for

Speed References

Speed/Torque

Control

Torque

Alarm

Process

Display

Done /

Exit

Selection:

1. Torq Prove

2. Pos/Spd Profile

3. Oil Well Pumps

Done /

Exit

Done /

Exit