3 detector, Pmt i/v – INFICON Guardian EIES Controller User Manual

Page 128

6 - 4

IP

N 07

4-

51

7-

P1

D

Guardian Co-Deposition Controller Operating Manual

However, for Cu the line near 3250 Å is not only attenuated, but is also near the

secondary Al line around 3100 Å. To accurately measure the Cu emission, we need

a discriminating device with the conflicting goals of a narrow bandwidth and low

attenuation of the desired signal.

Thin film optical filters are both efficient and selective. In addition they are readily

available, small, and relatively inexpensive. The main disadvantages are that a

specific filter is required for each material, and the filters degrade over time.

Periodic spectrometer verification of filter central wavelength and pass band is

required.

An alternative to optical filters are monochromators. Both wavelength and

bandwidth are tunable, but the efficiency does vary with the square of the

bandwidth. For applications requiring deposition of many different materials,

monochromator size and expense may be an acceptable trade-off to stocking and

changing filters.

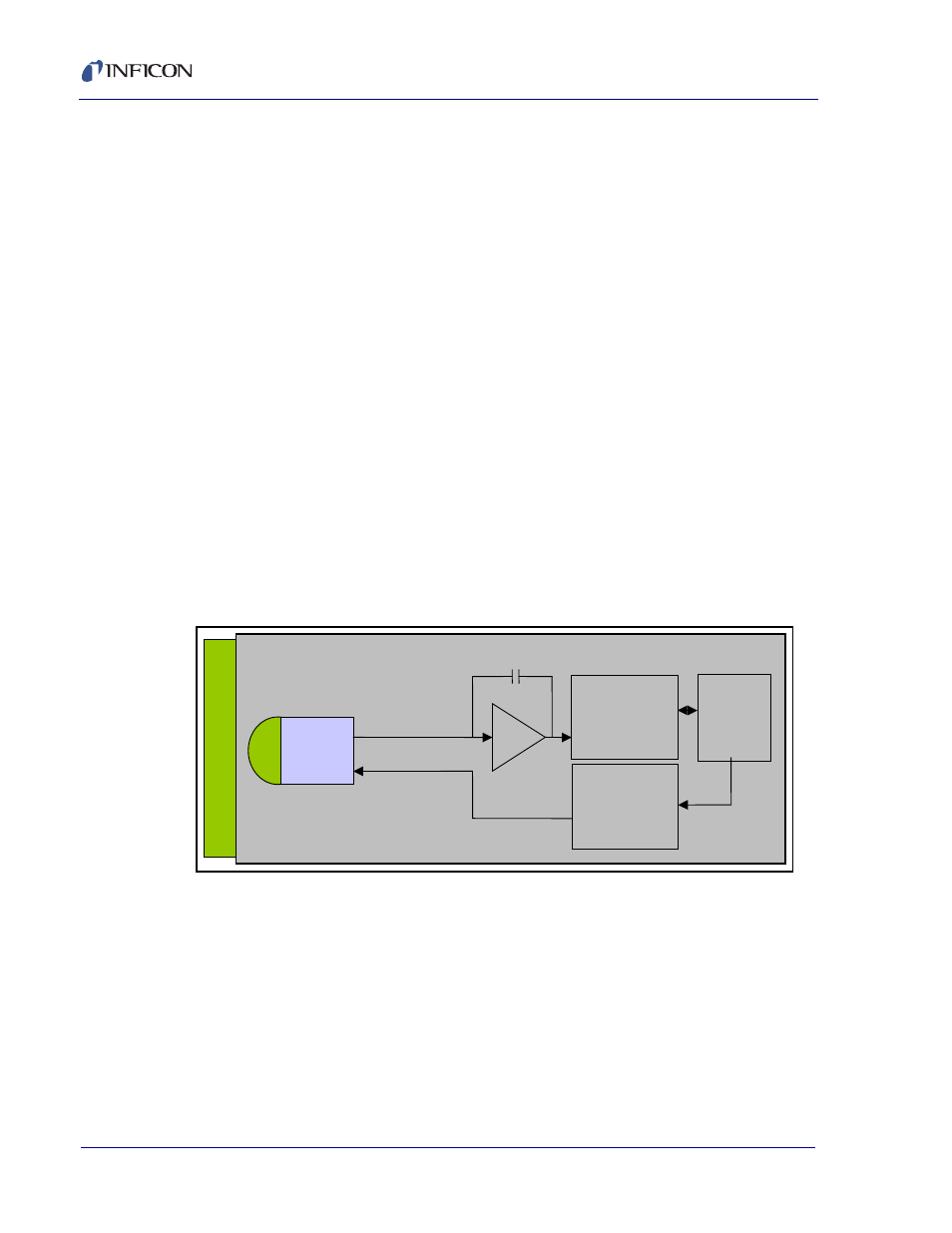

6.2.3 Detector

Once the characteristic wavelength is discriminated by a filter or monochromator,

it must be accurately measured by a detector. The EIES-IV Guardian uses a

photomultiplier tube (PMT) to convert the optical signal to electric current. See

.

Figure 6-3 PMT

In addition to the PMT, a programmable high voltage power supply and

microprocessor are housed within the detector module. This allows each detector

to be calibrated to a PMT voltage specific to the material and deposition rate being

measured. A single DB-9 cable carries the RS-232 communications and low

voltage power between the detector and Guardian controller.

0 - 1000V

20 Bit

D to A

32 Bit

C

Switching

Power

Supply

0 - 2500 nA

PMT

I/V

F

I

L

T

E

R

Δ-∑

μ