Festo DRRD-12 ... 63 User Manual

Page 21

DRRD-12 ... 63

Festo – DRRD-12 ... 63-Z6 – 1310b English

21

3. Feed the appropriate lines through the hollow

drive shaft, if necessary, or use the variant

with energy throughfeed.

The shaft opening for wiring has the following

dimensions (

Tab. 2).

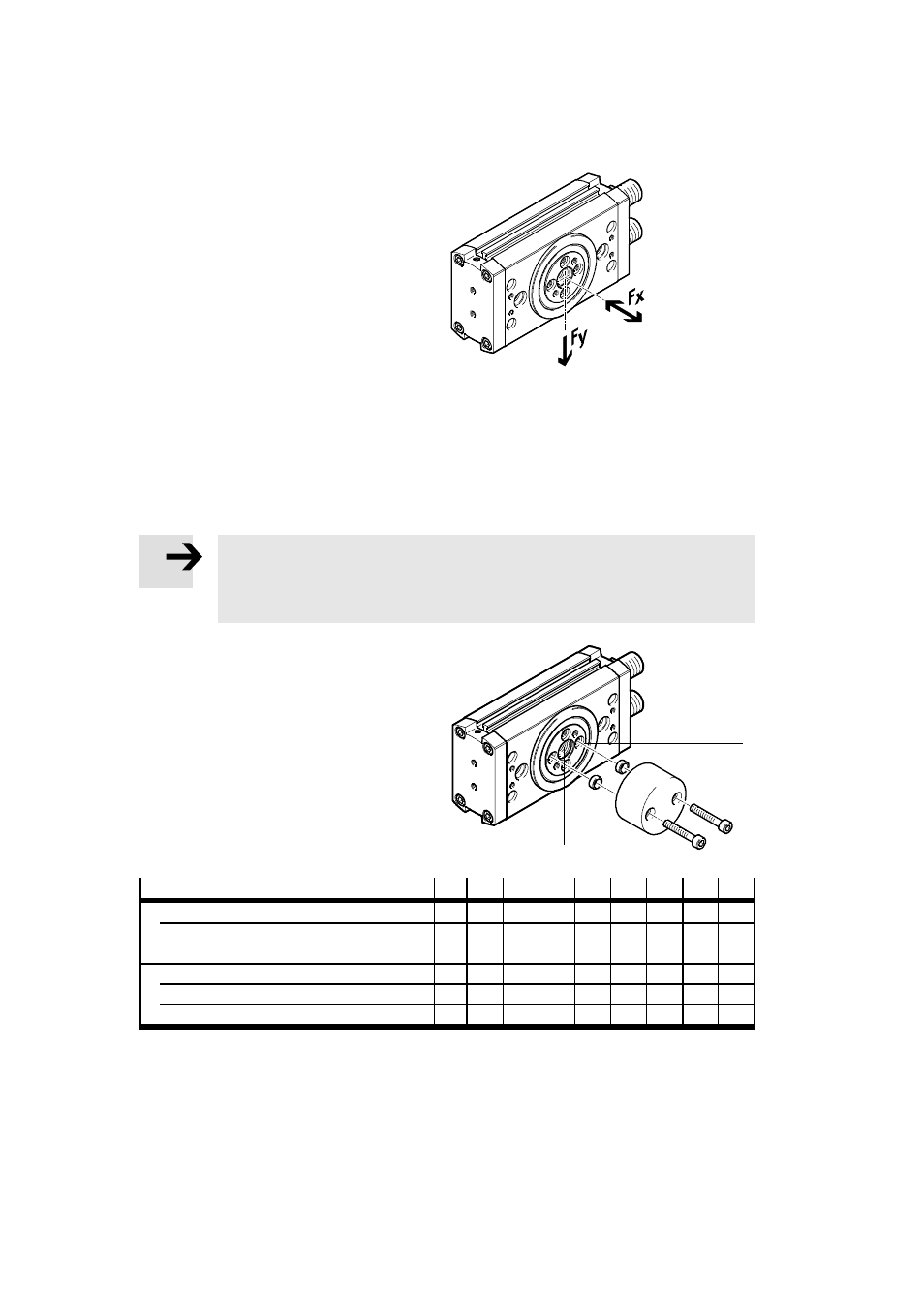

4. When mounting the moving mass, make sure

that the following specifications are observed:

–

installation without tilting

–

permissible radial force Fy

–

permissible axial force Fx

–

permissible mass moment of inertia

–

a structure that is as rotationally symmet-

rical as possible.

Fig. 3

The mass moment of inertia of the payload should be calculated. Lever arms, cantilevers and

masses should be considered in the calculation (maximum permissible values

Catalogue

specifications, www.festo.com/catalogue).

Note

If there are demanding requirements for concentricity of the components on the flanged

shaft:

•

Use the middle centring hole

4 as well as one of the 4 existing centring holes.

5. Secure the effective load to the drive flange at

the mounting interface

aA by using at least

two screws positioned opposite one another

and centring sleeves.

The tightening torque is summarised in the

following table (

Tab. 2).

aA

Fig. 4

4

Size

12

16

20

25

32

35

40

50

63

Shaft opening

4

[mm]

5

8

8

10.5 10.5 10.5 21

21

21

Centring sleeve ZBH for middle

centring hole

[mm]

7

12

12

15

15

25

25

25

25

Screw for thread at

aA

M3

M4

M4

M5

M6

M6

M6

M8

M10

Centring sleeve ZBH

[mm]

5

7

7

9

9

9

9

12

15

Tightening torque

[Nm]

1.2 3

3

6

10

10

10

20

40

Tab. 2