Class1 FoamLogix 2.1A & 1.7AHP REV D User Manual

Page 72

FoamLogix, Model 2.1A and 1.7AHP Class “A”

Electronic Foam Proportioning Systems

72

Note: Hale FoamLogix system electronic components

have no user serviceable components inside and are

replaced as a unit.

Opening of Hale FoamLogix electronic

components voids the manufacturer

warranty.

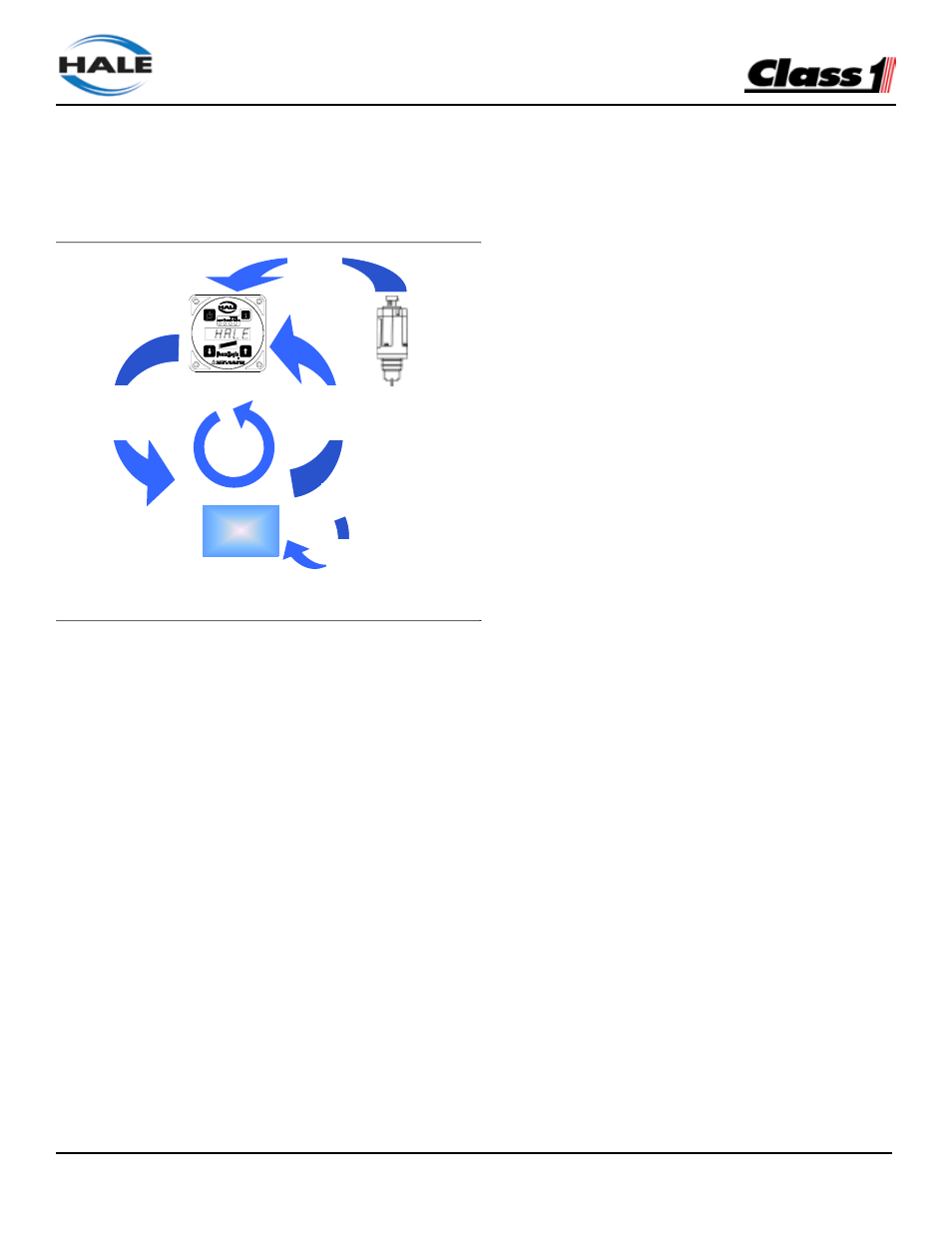

Water

Flow Data

Closed

Loop

System

FoamLogix Control

Display Unit

Foam Flow Data,

A or B Tank

Low Tank Data

Variable Speed

Instructions to

Motor

Water Flow

Sensor

Pump/Motor Base

Foam Flow

Data

Foam Flow

Sensor

Distribution

Box

Figure 43: FoamLogix 2.1A & 1.7AHP System Closed-Loop

Flow Diagram

System Overview

See Figure 43: “FoamLogix 2.1A and 1.7AHP

System Closed-Loop Flow Diagram.”

The FoamLogix 2.1A and 1.7AHP are “closed-

loop” systems. The brains behind the system is the

computer-controlled FoamLogix Control Display

Unit. As an electronic system, the flow of data

—”runs“ the system. A basic understanding of how

the system functions makes troubleshooting easier.

Water flow data is fed to the control unit computer.

Since the injection rate (%) is preset, the control

unit calculates the required motor speed of the foam

pump and sends this data to the motor. The output

of the pump is measured by a foam flow feedback

sensor.

The foam flow feedback sensor tells the control

unit how much foam is actually pumped so the

display can make the required motor speed

adjustments. This closed-loop runs several times

per second and is what makes the system so

accurate.

Note: The FoamLogix unit has a “simulated

flow“ function, described in Section 4:

“Operation” heading “Simulated Flow

Operation“ beginning on page 66. This allows

troubleshooting without flowing water, yet

simulates an actual water flow.

Distribution Box

The Distribution Box, part of the pump/motor

assembly, sends data on LOW tank warnings tank

selec tion status, as well as foam concen trate flow

feedback to the display.

LOW tank and Tank selection status are also

determined within the distribution box. A connector

at taches to selector valves. This connection signals

the control unit if the unit is in tank selected or flush

mode.

If no accessory is used, a connector plug is installed

to lock the system in the Tank A mode. (See Figure

20: “Control Harness Connections” on page 45.)

Removing this plug or disconnecting the MST

accessory cable places the system in the “flush“

mode.

Pump/Motor

The discharge of the foam pump directs foam to

the rotary lobe flow meter.

The rotors are a composite material con taining small

stainless steel targets. As the foam is being pumped,

a target lines up with the sensor in the pump head.