Simulated flow, Foam concentrate injection rate – Class1 FoamLogix 2.1A & 1.7AHP REV D User Manual

Page 55

FoamLogix, Model 2.1A and 1.7AHP Class “A”

Electronic Foam Proportioning Systems

55

Press the

3.

or button and set the reading to

match the actual flow calculated from the Pitot

gauge reading.

Decrease fire pump pressure by approxi mately

4.

one half (1/2) and recalculate water flow rate.

Verify the reading on the control unit is within 5%

of the actual value.

STOP the water flow when adjustments are

5.

completed.

Record Flow and Sensor Calibration Factors

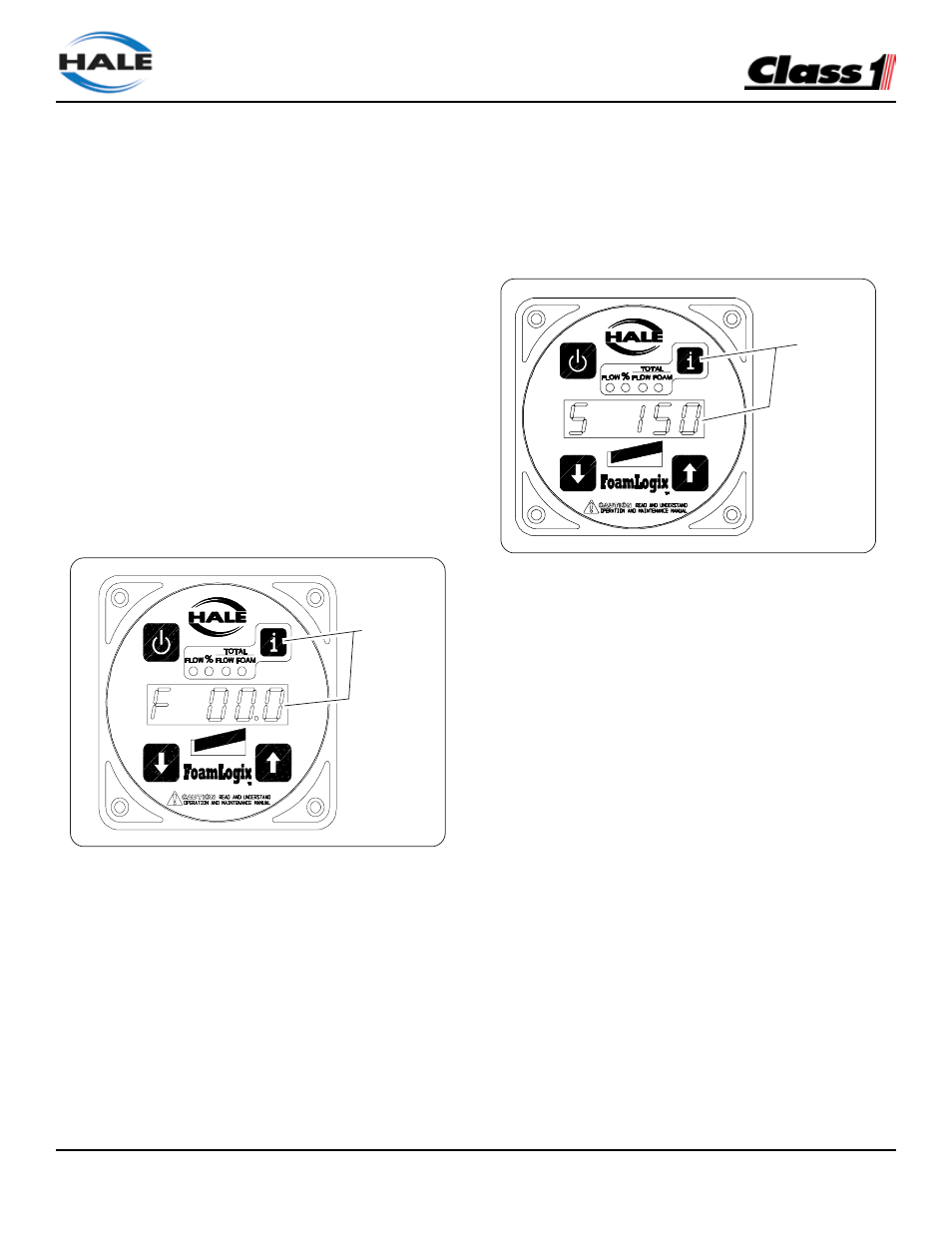

Press and release the

i button. The display show

F xx.x, which is the water flow sensor calibration

factor (See Figure 28: “Display Flow Sensor

Calibration Factor.”)

FOAMLOGIX, Model 2.1A Class "A"

53

Electronic Foam Proportioning System

Installation

ISO 9001 CERTIFIED

3. Press the

or button and set the

reading to match the actual flow calculated

from the Pitot gauge reading.

4. Decrease fire pump pressure by approxi-

mately one half (1/2) and recalculate water

flow rate.

Verify the reading on the control unit is

within 5% of the actual value.

5. STOP the water flow when adjustments

are completed.

Record Flow and Sensor Calibration

Factors

Press and release the

i

button. The display

show

F xx.x, which is the water flow sensor

calibration factor (See Figure 28: “Display -

Flow Sensor Calibration Factor.”)

Record this value for future reference. This

factor must be programmed into the display if

the display is ever replaced.

WATER FLOW SENSOR CALIBRATION

FACTOR: __________________________

SIMULATED FLOW

The default Simulated Flow value is factory set to

150 GPM (568 LPM) and, if necessary, may be

adjusted while in the user calibration mode.

Press the

i

button. The default simulated flow

rate is shown. (See Figure 29: “Display - Simu-

lated Flow Calibration.”)

Adjust the setting to the required rate by pressing

the or buttons (e.g.,

S 150).

FOAM CONCENTRATE INJECTION

RATE

When the Hale FoamLogix system power is

turned ON, the foam concentrate injection rate

stored in memory is the default setting. The user

specific default concentrate injection rate is

adjusted in calibration mode.

1. Press the

i button.

The display shows the current default

concentrate injection rate stored in the

computer memory for the selected foam

concentrate tank. (See Figure 30: “Display

- Foam Concentrate Injection Rate Default

Value” on page 52.)

Figure 28: Display - Flow Sensor Calibration Factor

Press and

release -

F xx.x

is shown

Figure 29: Display - Simulated Flow Calibration

Press and

release -

CAL is

shown

Figure 28: Display - Flow Sensor Calibration Factor

Record this value for future reference. This factor

must be programmed into the display if the display is

ever replaced.

WATER FLOW SENSOR CALIBRATION

FACTOR: __________________________

SIMULATED FLOW

The default Simulated Flow value is factory set to

150 GPM (568 LPM) and, if necessary, may be

adjusted while in the user calibration mode.

FOAMLOGIX, Model 2.1A Class "A"

53

Electronic Foam Proportioning System

Installation

ISO 9001 CERTIFIED

3. Press the

or button and set the

reading to match the actual flow calculated

from the Pitot gauge reading.

4. Decrease fire pump pressure by approxi-

mately one half (1/2) and recalculate water

flow rate.

Verify the reading on the control unit is

within 5% of the actual value.

5. STOP the water flow when adjustments

are completed.

Record Flow and Sensor Calibration

Factors

Press and release the

i

button. The display

show

F xx.x, which is the water flow sensor

calibration factor (See Figure 28: “Display -

Flow Sensor Calibration Factor.”)

Record this value for future reference. This

factor must be programmed into the display if

the display is ever replaced.

WATER FLOW SENSOR CALIBRATION

FACTOR: __________________________

SIMULATED FLOW

The default Simulated Flow value is factory set to

150 GPM (568 LPM) and, if necessary, may be

adjusted while in the user calibration mode.

Press the

i

button. The default simulated flow

rate is shown. (See Figure 29: “Display - Simu-

lated Flow Calibration.”)

Adjust the setting to the required rate by pressing

the or buttons (e.g.,

S 150).

FOAM CONCENTRATE INJECTION

RATE

When the Hale FoamLogix system power is

turned ON, the foam concentrate injection rate

stored in memory is the default setting. The user

specific default concentrate injection rate is

adjusted in calibration mode.

1. Press the

i button.

The display shows the current default

concentrate injection rate stored in the

computer memory for the selected foam

concentrate tank. (See Figure 30: “Display

- Foam Concentrate Injection Rate Default

Value” on page 52.)

Figure 28: Display - Flow Sensor Calibration Factor

Press and

release -

F xx.x

is shown

Figure 29: Display - Simulated Flow Calibration

Press and

release -

CAL is

shown

Figure 29: Display - Simulated Flow Calibration

Press the

i button. The default simulated flow rate

is shown. (See Figure 29: “Display - Simu lated Flow

Calibration.”)

Adjust the setting to the required rate by pressing

the or buttons (e.g.,

S 150).

FOAM CONCENTRATE INJECTION RATE

When the Hale FoamLogix system power is turned

ON, the foam concentrate injection rate stored in

memory is the default setting. The user specific

default concentrate injection rate is adjusted in

calibration mode.

1. Press the

i button.

The display shows the current default concentrate

injection rate stored in the computer memory for the

selected foam concentrate tank. (See Figure 30:

“Display Foam Concentrate Injection Rate Default

Value” on page 56.)