Class1 FoamLogix 2.1A & 1.7AHP REV D User Manual

Page 33

FoamLogix, Model 2.1A and 1.7AHP Class “A”

Electronic Foam Proportioning Systems

33

Table 6: Recommended Primary Power Cable Sizes

Models 3.3 and 5.0

Maximum length

8 AWG (8.4mm

2

)

6’ (1.8M) or less

4 AWG (21.2mm

2

)

6; (1.8M) to 15” (4.6M)

0 AWG (53.5mm

2

)

15’ (4.6M) or Longer

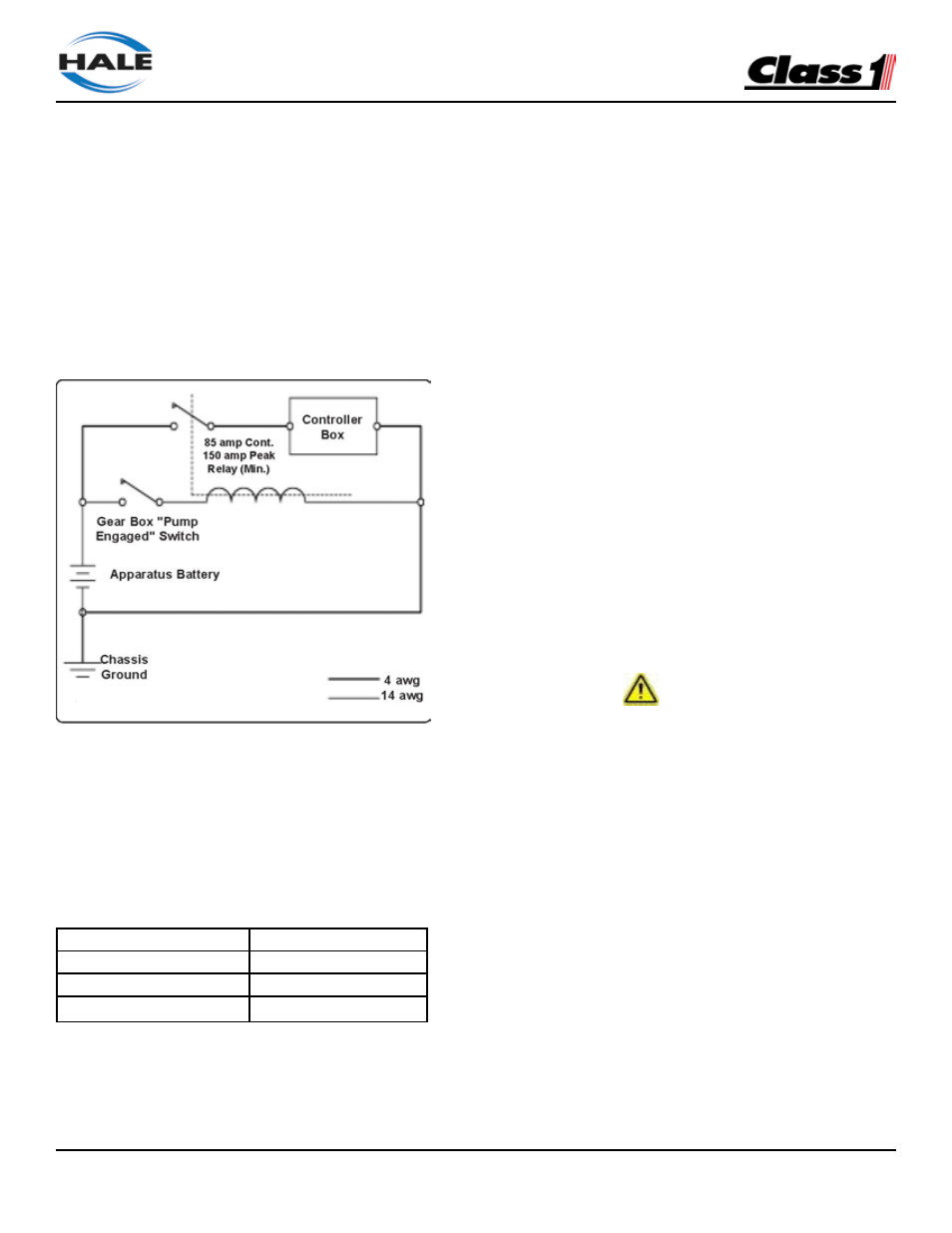

that power is supplied to the Hale Foam-Logix when

the main apparatus electrical system is energized

and the pump is in gear. Use of a solenoid with

a 150 AMP peak, 85 AMP continuous rating is

recommended. Figure 5: “Recommended Relay

Wiring Schematic” shows the recom mended wiring

for this relay.

Note: This ensures immediate operation when

the operator places the apparatus in PUMP mode,

and to prevent battery power drain when the

apparatus is not running.

With Hale FoamLogix 2.1A and 1.7AHP cable

lengths up to 6’ (1.8 meters) require a minimum 8

AWG type SGX (SAE J1127) battery cable. (See

Table 6: “Recommended Primary Power Cable

Sizes.”) Use solder lugs on cable ends with a 5/16”

(8mm) diameter hole.

When planning cable runs make sure the primary

wires are routed by the shortest most direct route.

A braided flat ground strap connected to the

apparatus chassis is recommended for the ground

connection.

This limits the RFI/EMI interference encoun tered

with radios, computers or other sensi tive electronic

equipment. The ground strap should be a minimum

of 1-1/4” (32mm) wide and no longer than 18”

(457mm). It must have soldered flat lug ends with

3/8” (10mm) diameter holes. If the ground strap

length exceeds 18” (457mm), a wider ground strap

should be used or use a double thickness of 1-1/4”

(32mm) wide ground strap. The ground strap must

be connected to the chassis. Use minimum 5/16” (8

mm) diam eter bolt or mounting to secure the strap.

Power and ground must also be provided for the

display unit using the 2 pin Packard connector. The

power must be a minimum 5 amp dedicated and

fused circuit. The ground must be connected to the

chassis ground stud and protected from corrosion.

Make sure the ground is attached directly to the

chassis frame and not to the apparatus body work.

IMPORTANT!

BEFORE MAKING GROUND CONNECTIONS REMOVE

ALL PAINT, GREASE AND COATINGS FROM THE

CONNECTION AREA. AFTER MAKING CONNECTION,

SEAL AGAINST CORROSION. WHEN A FLAT GROUND

STRAP IS NOT AVAIL ABLE USE A BATTERY CABLE

ONE SIZE LARGER THAN THE POWER CABLE USED.

FOAM CONCENTRATE TANK

A foam concentrate tank must be supplied to suit

the capacity required for the apparatus application.

The tank must meet NFPA minimum standards for

its design capacity, including:

❑

Filler size

❑

Vapor pressure venting

❑

Baffling

❑

Drain facilities.

Figure 5: Recommended Relay Wiring Schematic