Low pressure strainer, Ordering information – Class1 FoamLogix 2.1A & 1.7AHP REV D User Manual

Page 16

FoamLogix, Model 2.1A and 1.7AHP Class “A”

Electronic Foam Proportioning Systems

16

The motor speed is constantly adjusted to main tain

the operator selected foam concentrate injection

rate. Since the system is flow based, injection rate

remains constant regardless of changes in system

pressure or the number of discharges that are open

(within the limits of the sytem).

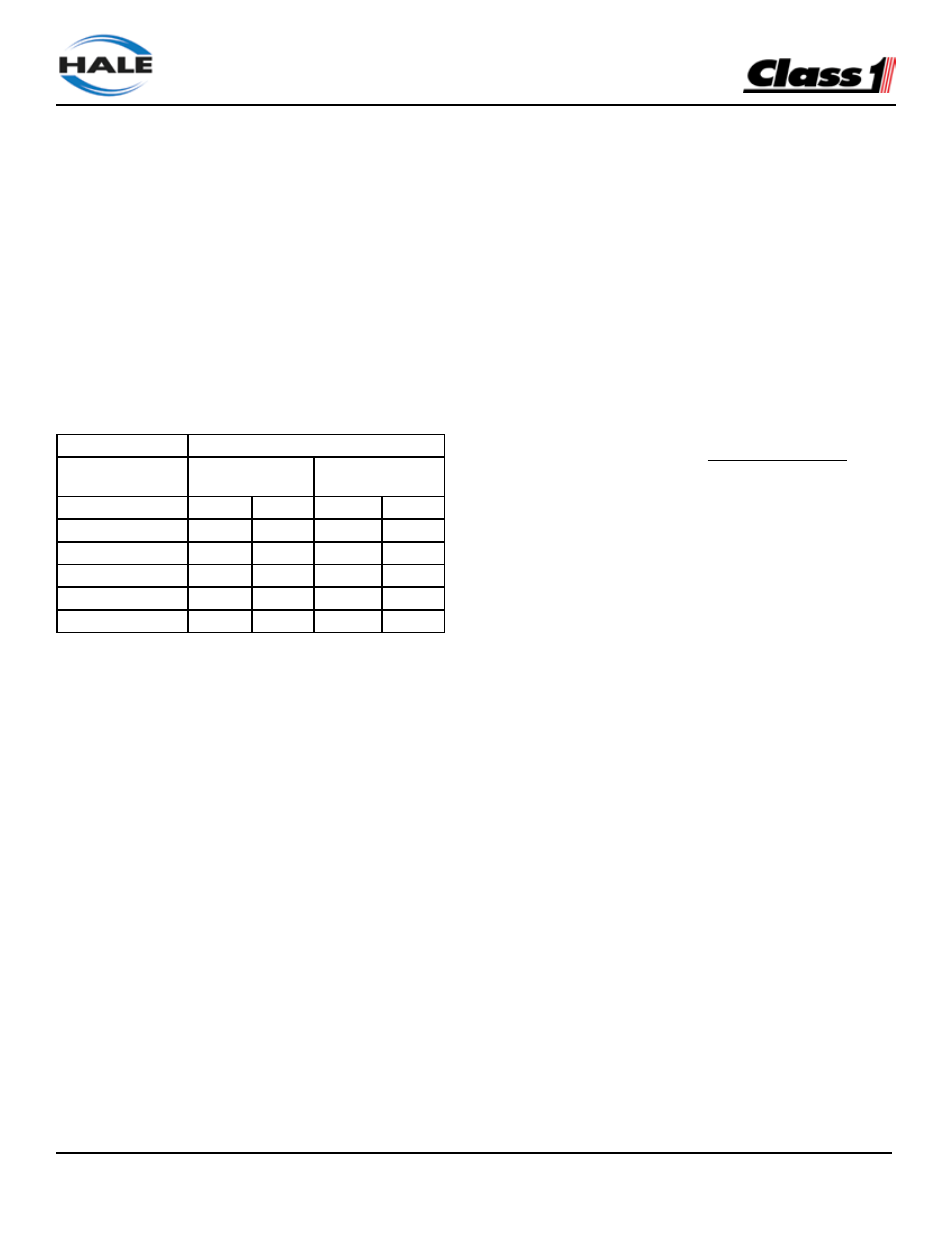

The maximum rated foam concentrate flow, in

gallons per minute, is denoted by the model

number. Table 1: “Maximum Foam Solution

Flows” shows the system capacity at various foam

concentrate injection rates for the Hale FoamLogix

2.1A and 1.7APH units.

Maximum Foam Solution Flow

Injection Rate

Percent (%)

Gallons per

Minute (GPM)

Liters Per Minute

(LPM)

2.1A

1.7AHP 2.1A

1.7AHP

0.1

2,100

1,700

7,949

6,426

0.2

1,050

850

3,974

3,213

0.3

700

567

2,650

2,143

0.5

420

340

1,590

1,285

1.0

210

170

795

643

Table 1: Maximum Foam Solution Flows

The Hale FoamLogix 2.1A & 1.7A Foam system

configu ration is shown in Figure 2-3: “Typical

System Layout” on page 21.

LOW PRESSURE STRAINER

A low pressure foam concentrate strainer is mounted

at the inlet of the foam pump. The strainer protects

the pump from debris that might accumulate in the

foam concentrate tank. The strainer/valve assembly

has a composite nonme tallic housing with stainless

steel mesh strainer element and includes a service

shut-off valve.

The valve inlet offers 1/2” NPT (13 mm) threads,

with a fitting to connect a 1/2” (13 mm) ID foam

concentrate suction hose.

The strainer and valve are low pressure devices

and are designed for installations where the

strainer IS NOT subject to HIGH pressure flush ing

water.

ORDERING INFORMATION

Ordering Hale FoamLogix 2.1A and 1.7AHP

Foam Systems is simple. Using the current Hale

FoamLogix 2.1A Foam System Price List and

Order Form helps ensure a complete matched

system is provided to the end user.

Use the following procedure when ordering a

Hale FoamLogix 2.1A Foam system. Following

all steps to ensure that a complete system is

ordered:

Check Hale Foam system product informa-

1.

tion update (Bulletin #961) for the latest

information and advice for foam system

selection.

Determine the Class “A” foam concentrate

2.

to be used in the system and ensure system

compatibility by referring to the Hale Foam

Concentrate Compatibility list (Bulletin #650).

Consult the current Hale FoamLogix 2.1A/

3.

1.7AHP Price List and Order Form for

ordering of the system.

The Hale FoamLogix 2.1A and 1.7AHP can be

ordered as one of two pre-configured packages

that include the pump and motor assem bly,

control unit, flow sensor cable, stain less steel

check valve and injection mani fold, and an

installation kit.

Package “A” includes the single check

valve manifold.