Foam pump feedback calibration – Class1 FoamLogix 2.1A & 1.7AHP REV D User Manual

Page 56

FoamLogix, Model 2.1A and 1.7AHP Class “A”

Electronic Foam Proportioning Systems

56

54

FOAMLOGIX, Model 2.1A Class "A"

Electronic Foam Proportioning System

Installation

ISO 9001 CERTIFIED

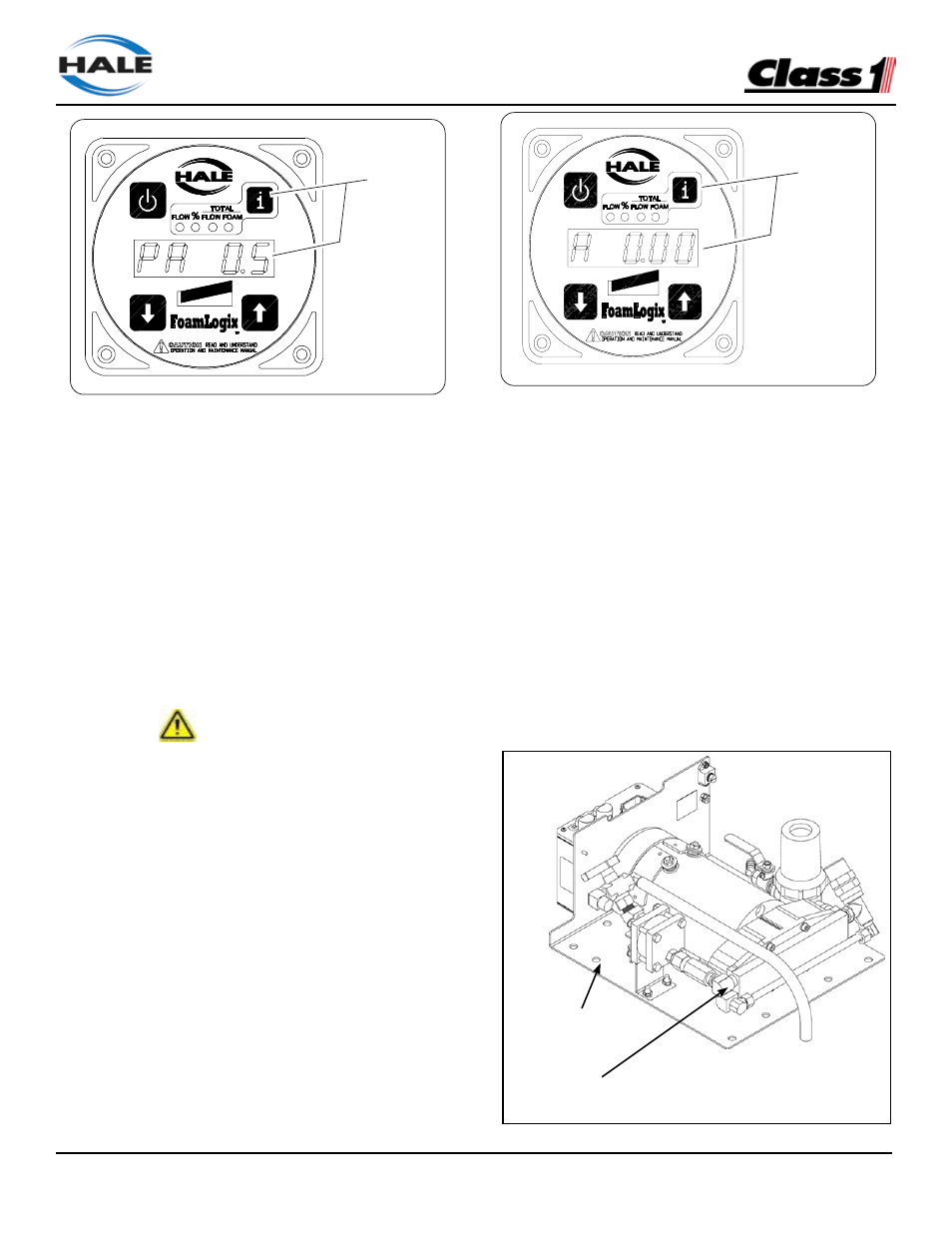

2. If the factory default values have not been

changed the display shows

PA 0.5.

3. Use the or buttons to set the user

specified default concentrate injection rate.

FOAM PUMP FEEDBACK

CALIBRATION

IMPORTANT!

FOAM PUMP FEEDBACK IS CALIBRATED AFTER

INSTALLATION TO VERIFY VALUES WITH THE

ACTUAL FOAM CONCENTRATE(S) BEING USED.

ONLY CALIBRATE USING ACTUAL FOAM CON-

CENTRATES.

DO NOT USE WATER, TRAINING OR TEST FOAMS

FOR FEEDBACK CALIBRATION VERIFICATION.

1. Press the

i button.

The display shows

A x.xx, the total vol-

ume of foam concentrate pumped during

the last calibration run. (See Figure 31:

“Display - Foam Pump Feedback Calibra-

tion.”)

2. Set the bypass valve to the

BYPASS.

3. Place a graduated measure container at

the outlet of the bypass hose capable of

containing the expected volume of foam

concentrate, 5 gallons (19 liters) minimum.

(See Figure 32: “Foam Concentrate

Collection.”).

Note: If an accurate calibrated container is

not available an accurate scale can be used

to weigh the foam concentrate pumped. The

total volume of foam concentrate is then

calculated from this weight and the density of

the foam concentrate per the MSDS sheet.

Figure 30: Display - Foam Concentrate Injection Rate

Default Value

Press and

release - the

default value is

shown

Figure 32: Foam Concentrate Collection

Measuring

(calibrated)

Container

Bypass Valve on

Foam Pump

Bypass Hose

Figure 31: Display - Foam Pump Feedback Calibration

Press and

release - the

present value is

shown

Figure 30: Display - Foam Concentrate Injection Rate

Default Value

2

.

If the factory default values have not been

changed the display shows

PA 0.5.

3. Use the or buttons to set the user specified

default concentrate injection rate.

FOAM PUMP FEEDBACK CALIBRATION

IMPORTANT!

FOAM PUMP FEEDBACK IS CALIBRATED AFTER

INSTALLATION TO VERIFY VALUES WITH THE

ACTUAL FOAM CONCENTRATE(S) BEING USED.

ONLY CALIBRATE USING ACTUAL FOAM CON-

CENTRATES.

DO NOT USE WATER, TRAINING OR TEST FOAMS

FOR FEEDBACK CALIBRATION VERIFICATION.

1. Press the

i button.

The display shows

A x.xx, the total vol ume of foam

concentrate pumped during the last calibration run.

(See Figure 31: “Display - Foam Pump Feedback

Calibra tion.”)

2. Set the bypass valve to the

BYPASS.

54

FOAMLOGIX, Model 2.1A Class "A"

Electronic Foam Proportioning System

Installation

ISO 9001 CERTIFIED

2. If the factory default values have not been

changed the display shows

PA 0.5.

3. Use the or buttons to set the user

specified default concentrate injection rate.

FOAM PUMP FEEDBACK

CALIBRATION

IMPORTANT!

FOAM PUMP FEEDBACK IS CALIBRATED AFTER

INSTALLATION TO VERIFY VALUES WITH THE

ACTUAL FOAM CONCENTRATE(S) BEING USED.

ONLY CALIBRATE USING ACTUAL FOAM CON-

CENTRATES.

DO NOT USE WATER, TRAINING OR TEST FOAMS

FOR FEEDBACK CALIBRATION VERIFICATION.

1. Press the

i button.

The display shows

A x.xx, the total vol-

ume of foam concentrate pumped during

the last calibration run. (See Figure 31:

“Display - Foam Pump Feedback Calibra-

tion.”)

2. Set the bypass valve to the

BYPASS.

3. Place a graduated measure container at

the outlet of the bypass hose capable of

containing the expected volume of foam

concentrate, 5 gallons (19 liters) minimum.

(See Figure 32: “Foam Concentrate

Collection.”).

Note: If an accurate calibrated container is

not available an accurate scale can be used

to weigh the foam concentrate pumped. The

total volume of foam concentrate is then

calculated from this weight and the density of

the foam concentrate per the MSDS sheet.

Figure 30: Display - Foam Concentrate Injection Rate

Default Value

Press and

release - the

default value is

shown

Figure 32: Foam Concentrate Collection

Measuring

(calibrated)

Container

Bypass Valve on

Foam Pump

Bypass Hose

Figure 31: Display - Foam Pump Feedback Calibration

Press and

release - the

present value is

shown

Figure 31: Display - Foam Pump Feedback Calibration

3.

Place a graduated measure container at the

outlet of the bypass hose capable of containing

the expected volume of foam concentrate, 5

gallons (19 liters) minimum.

(See Figure 32: “Foam Concentrate Collection.”)

Note: If an accurate calibrated container is not

available an accurate scale can be used to

weigh the foam concentrate pumped. The total

volume of foam concentrate is then calculated

from this weight and the density of the foam

concentrate per the MSDS sheet.

Bypass Hose

Bypass Valve

on Foam

Pump

Figure 32: Foam Concentrate Collection