Class1 FoamLogix 2.1A & 1.7AHP REV D User Manual

Page 35

FoamLogix, Model 2.1A and 1.7AHP Class “A”

Electronic Foam Proportioning Systems

35

The diagram provides recommended guidelines for

the installation of system components that handle

water, foam concentrate and foam solu tion. The

sequence in which the plumbing installation is

completed depends on your indi vidual installation.

Water and Foam Solution Plumbing

When installing water and foam solution piping runs,

use best industry practices to install this piping. Use

a suitable pipe sealing compound at all joints.

Check Valve Manifold

Hale pre-made stainless steel foam manifolds

are recommended.

The manifolds are available in kits and elimi nate

the extra labor and leaks from large pipe thread

connections.

The manifolds use 3” (76mm) Victaulic

connections and are available in single or dual

check valve configurations.

Figure 9: “Check Valve Manifold Installation,” on

page 36, shows a typical check valve manifold

installation.

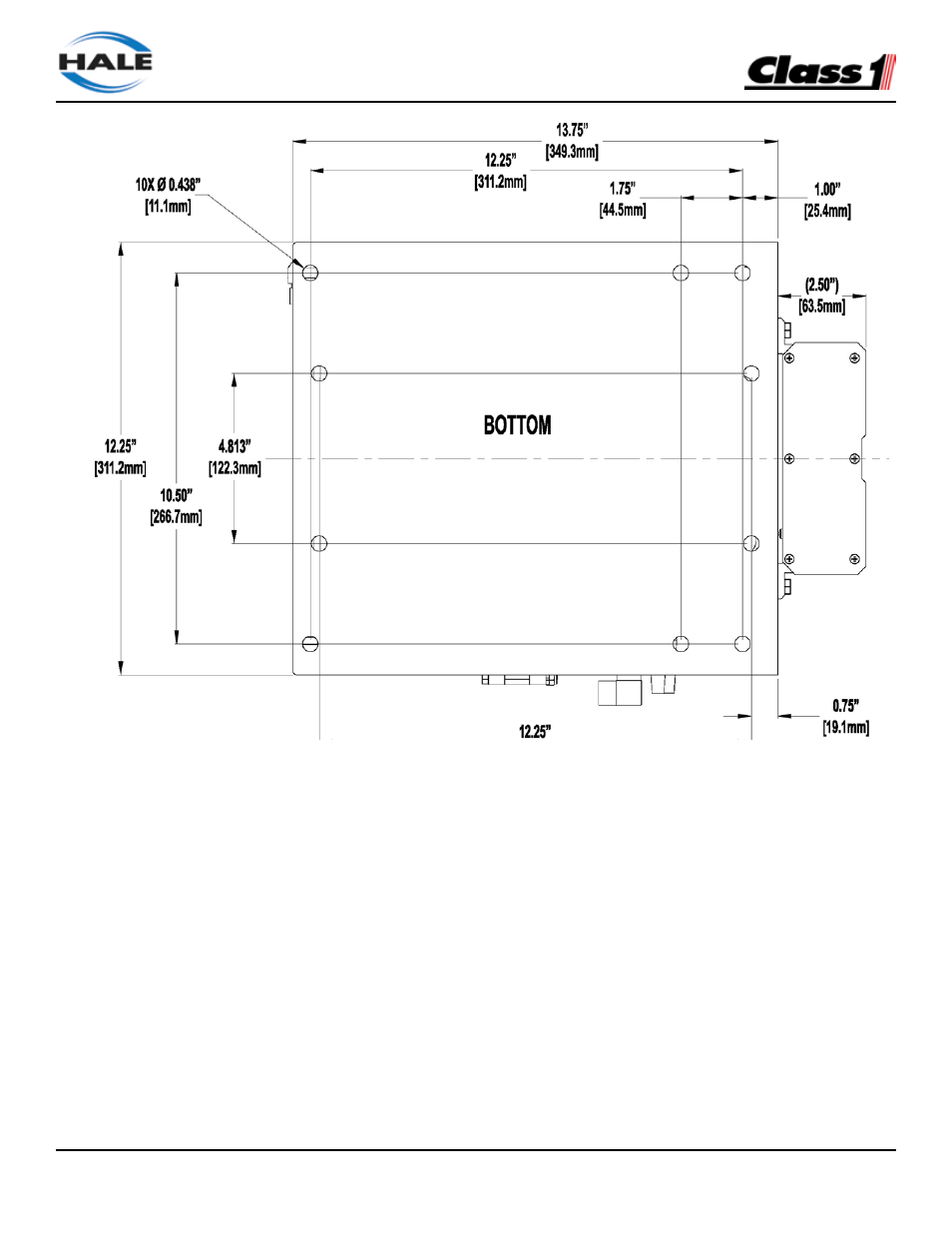

Figure 8: Base Plate Mounting Hole Locations