Troubleshooting, User diagnostics – Class1 FoamLogix 2.1A & 1.7AHP REV D User Manual

Page 71

FoamLogix, Model 2.1A and 1.7AHP Class “A”

Electronic Foam Proportioning Systems

71

USER DIAGNOSTICS

Power indicator lamps are provided on the

distribution box and on the feedback sensor. The

LED on the feedback sensor flashes when the

sensor is receiving pulses from the flow sensor rotor

targets. These LEDs help to ease tracing of power

supply faults and eliminates some of the guesswork

in troubleshooting. If the system malfunctions make

sure the follow ing conditions are checked:

❑

All hose connections correct and tight (Refer to

appropriate system plumbing diagram in Section

3 “Installation.”)

❑

All electrical connections correct and tight (Refer

to appropriate system electrical diagram in

Section 3 “Installation.”)

❑

Apparatus electrical system energized with

power supplied to pump panel and Hale

FoamLogix.

Once the above conditions are met, proceed to the

system troubleshooting section to determine the

cause of the malfunction.

Hale FoamLogix systems consist of individual

subsystems working together to provide finished

foam solution at the proper percentage. Also see

heading “System Overview” on page 72.

The system is designed using modular compo-

nents making troubleshooting and repair easier.

Each subsystem has its own set of troubleshoot-

ing procedures. The procedures that follow provide

a logical flow path to isolate and correct a system

failure.

SECTION 6 TROUBLESHOOTING

FOAMLOGIX, Model 2.1A Class "A"

69

Electronic Foam Proportioning System

Troubleshooting

ISO 9001 CERTIFIED

SECTION

6

TROUBLESHOOTING

USER DIAGNOSTICS

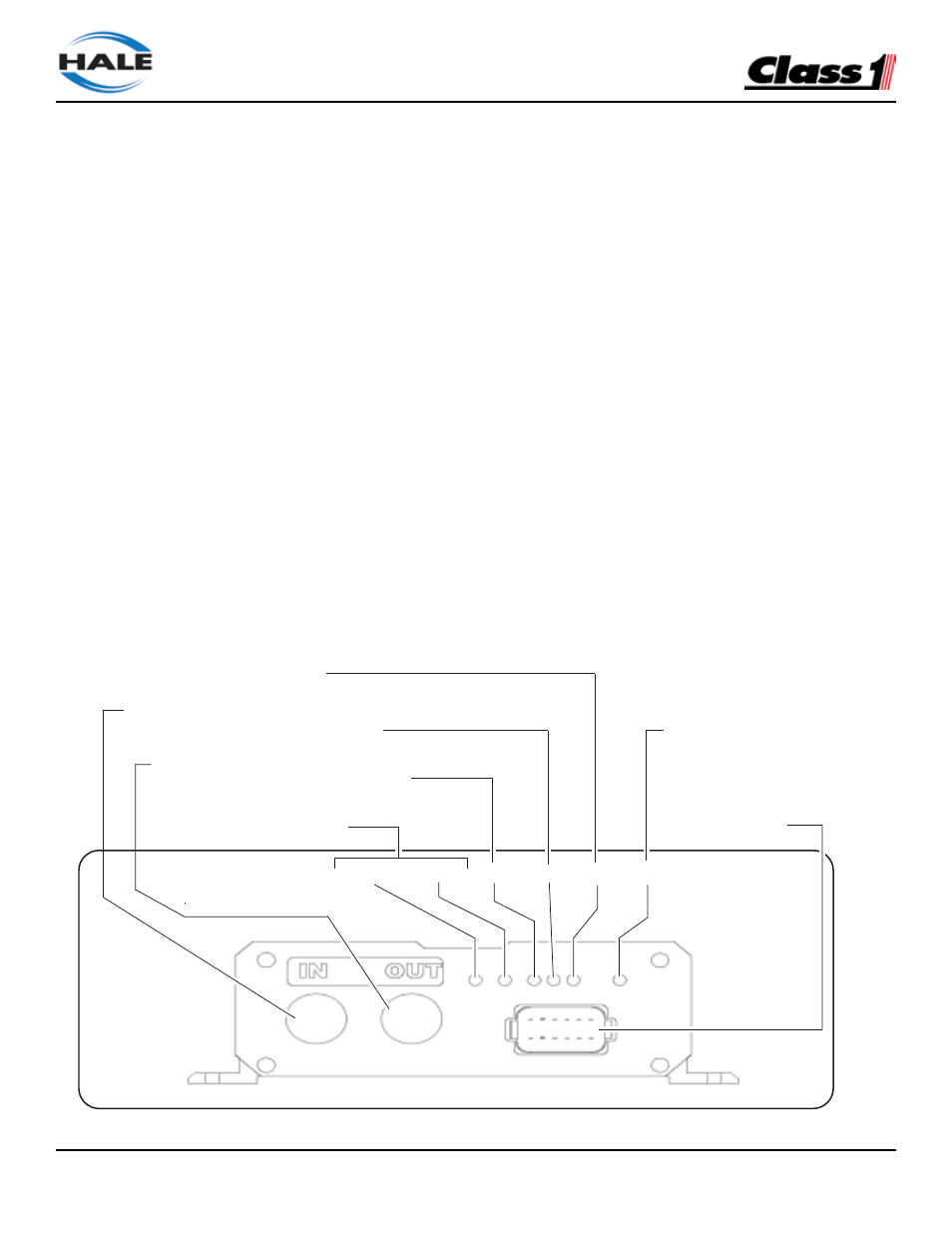

Power indicator lamps are provided on the

distribution box and on the feedback sensor. The

LED on the feedback sensor flashes when the

sensor is receiving pulses from the flow sensor

rotor targets. These LEDs help to ease tracing of

power supply faults and eliminates some of the

guesswork in troubleshooting. (See Figure 42:

“Distribution Box Overview.”)

If the system malfunctions make sure the follow-

ing conditions are checked:

❑

All hose connections correct and tight

(Refer to appropriate system plumbing

diagram in Section 3 “Installation.”)

❑

All electrical connections correct and tight

(Refer to appropriate system electrical

diagram in Section 3 “Installation.”)

❑

Apparatus electrical system energized

with power supplied to pump panel and

Hale FoamLogix.

Once the above conditions are met, proceed to

the system troubleshooting section to determine

the cause of the malfunction.

Hale FoamLogix systems consist of individual

subsystems working together to provide finished

foam solution at the proper percentage. Also see

heading “System Overview” on page 70.

The system is designed using modular compo-

nents making troubleshooting and repair easier.

Each subsystem has its own set of troubleshoot-

ing procedures. The procedures that follow

provide a logical flow path to isolate and correct a

system failure.

Distribution Box,

Top View

COM

TANK A

VIGN DPWR

TANK B VCC

Figure 42: Distribution Box Overview

Tank Selection

LEDs

5VDC Logic Power

DC Power Available to

Module

DC Power Available to

Motor

Module Status -

Steady = OnLine

Slow flash = NO communication

from controller

Fast flash = CAN BUS Error

Main DC Power

Connection

DC Power to

Motor

Main Control

Harness