Exit and save calibration – Class1 FoamLogix 2.1A & 1.7AHP REV D User Manual

Page 57

FoamLogix, Model 2.1A and 1.7AHP Class “A”

Electronic Foam Proportioning Systems

57

4. Start the Hale FoamLogix foam pump by pressing

the red

ON button.

The LEDs on the horizontal bar graph lights as

the foam pump begins operating at approximately

two-thirds speed, pump ing foam concentrate into

the container.

The display shows the volume of foam

concentrate being pumped.

5. STOP the foam pump and accurately measure

the amount of foam concentrate collected.

6. Adjust the reading on the display to match the

volume actually pumped using the or

button.

7. Repeat the procedure to verify the setting is

correct.

8. Set the bypass valve handle back to

INJECT

position.

Record Foam Pump Feedback Calibration

Factor

1. Press and release the

i button.

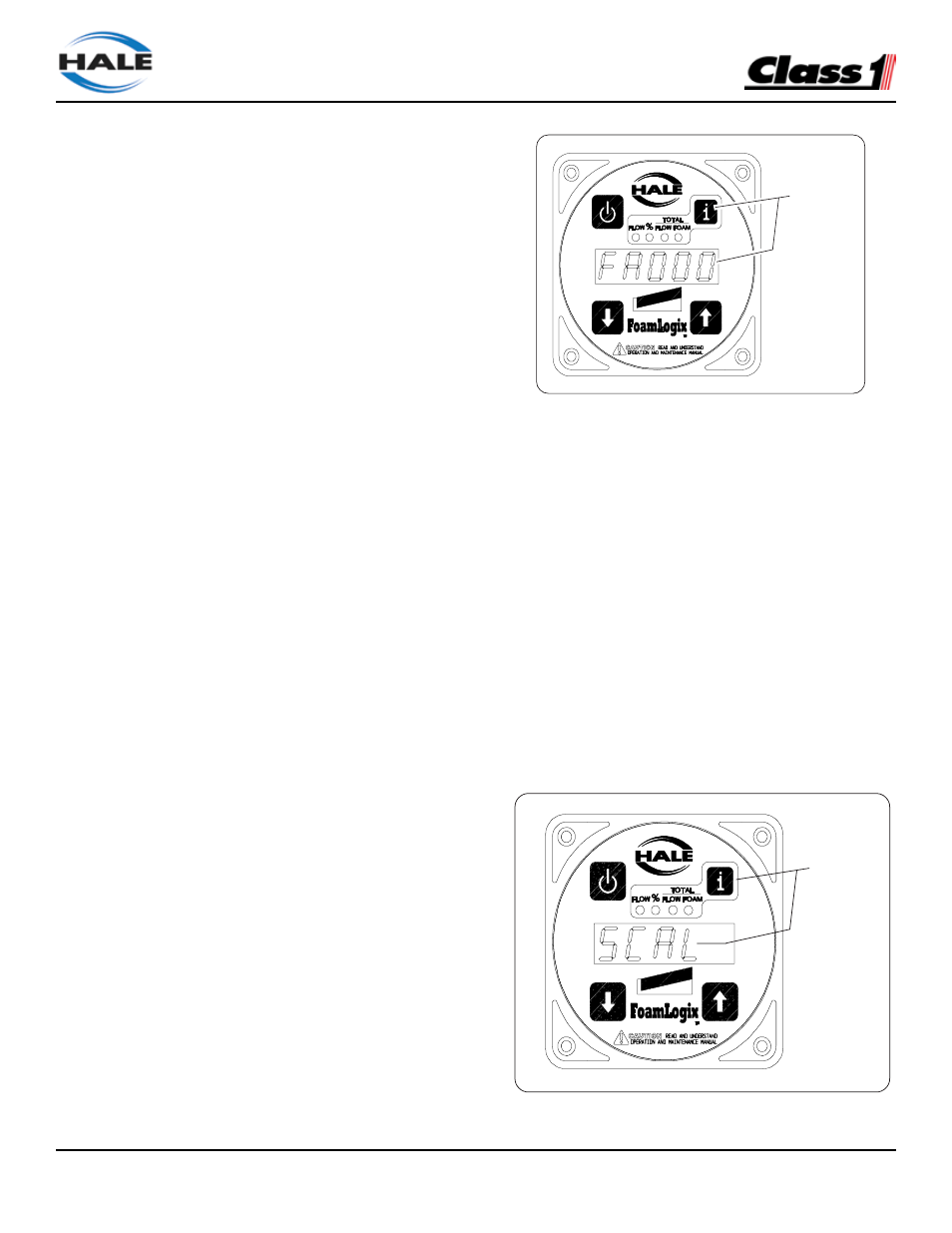

The display shows

FA xxx,the foam pump

feedback calibration factor.

(See Figure 33:

“Display - Foam Pump Feedback Calibration

Factor.”)

2. Record this value for future reference. This

factor must be programmed into the display if

the display is ever replaced.

FOAM PUMP FEEDBACK CALIBRATION

FACTOR: __________________________

EXIT AND SAVE CALIBRATION

1. To exit calibration and save the set values,

press and hold the

i button.

Figure 33: Display - Foam Pump Feedback Calibration

Factor

The display show

PASS, then clears.

2. While continuing to hold the display button

enter the password ().

3. The display shows

SCAL for several seconds and

then cycles through the start-up sequence

followed by the flow display

O. (See Figure 34:

“Display - Exit and Save Calibration.”)

This completes verification and adjustment of the

system. The Hale FoamLogix system is now ready

to be placed in service.

FOAMLOGIX, Model 2.1A Class "A"

55

Electronic Foam Proportioning System

Installation

ISO 9001 CERTIFIED

4. Start the Hale FoamLogix foam pump by

pressing the red

ON button.

The LEDs on the horizontal bar graph

lights as the foam pump begins operating

at approximately two-thirds speed, pump-

ing foam concentrate into the container.

The display shows the volume of foam

concentrate being pumped.

5. STOP the foam pump and accurately

measure the amount of foam concentrate

collected.

6.

Adjust the reading on the display to match

the volume actually pumped using the

or button.

7. Repeat the procedure to verify the setting

is correct.

8. Set the bypass valve handle back to

INJECT position.

Record Foam Pump Feedback

Calibration Factor

1. Press and release the

i button.

The display shows

FA xxx, the foam pump

feedback calibration factor. (See Figure

33: “Display - Foam Pump Feedback

Calibration Factor.”)

2. Record this value for future reference.

This factor must be programmed into the

display if the display is ever replaced.

FOAM PUMP FEEDBACK CALIBRATION

FACTOR: __________________________

EXIT AND SAVE CALIBRATION

1. To exit calibration and save the set values,

press and hold the

i button.

The display show

PASS, then clears.

2. While continuing to hold the display button

enter the password ().

3. The display shows

SCAL for several

seconds then cycles through the start-up

sequence followed by the flow display

O.

(See Figure 34: “Display - Exit and Save

Calibration.”)

This completes verification and adjustment of the

system. The Hale FoamLogix system is now

ready to be placed in service.

Figure 33: Display - Foam Pump Feedback Calibration

Factor

Press and

release - the

feedback factor

is shown

Press and

release -

SCAL

is shown

Figure 34: Display - Exit and Save Calibration

Figure 34: Display - Exit and Save Calibration

FOAMLOGIX, Model 2.1A Class "A"

55

Electronic Foam Proportioning System

Installation

ISO 9001 CERTIFIED

4. Start the Hale FoamLogix foam pump by

pressing the red

ON button.

The LEDs on the horizontal bar graph

lights as the foam pump begins operating

at approximately two-thirds speed, pump-

ing foam concentrate into the container.

The display shows the volume of foam

concentrate being pumped.

5. STOP the foam pump and accurately

measure the amount of foam concentrate

collected.

6.

Adjust the reading on the display to match

the volume actually pumped using the

or button.

7. Repeat the procedure to verify the setting

is correct.

8. Set the bypass valve handle back to

INJECT position.

Record Foam Pump Feedback

Calibration Factor

1. Press and release the

i button.

The display shows

FA xxx, the foam pump

feedback calibration factor. (See Figure

33: “Display - Foam Pump Feedback

Calibration Factor.”)

2. Record this value for future reference.

This factor must be programmed into the

display if the display is ever replaced.

FOAM PUMP FEEDBACK CALIBRATION

FACTOR: __________________________

EXIT AND SAVE CALIBRATION

1. To exit calibration and save the set values,

press and hold the

i button.

The display show

PASS, then clears.

2. While continuing to hold the display button

enter the password ().

3. The display shows

SCAL for several

seconds then cycles through the start-up

sequence followed by the flow display

O.

(See Figure 34: “Display - Exit and Save

Calibration.”)

This completes verification and adjustment of the

system. The Hale FoamLogix system is now

ready to be placed in service.

Figure 33: Display - Foam Pump Feedback Calibration

Factor

Press and

release - the

feedback factor

is shown

Press and

release -

SCAL

is shown

Figure 34: Display - Exit and Save Calibration