Class1 FoamLogix 2.1A & 1.7AHP REV D User Manual

Page 39

FoamLogix, Model 2.1A and 1.7AHP Class “A”

Electronic Foam Proportioning Systems

39

2. The downstream piping length is not as

critical, but there must be a short length

of straight pipe with no fittings or valves

immediately after the flow sensor paddle

wheel. Two to three times the pipe diam eter

is recommended.

37

37

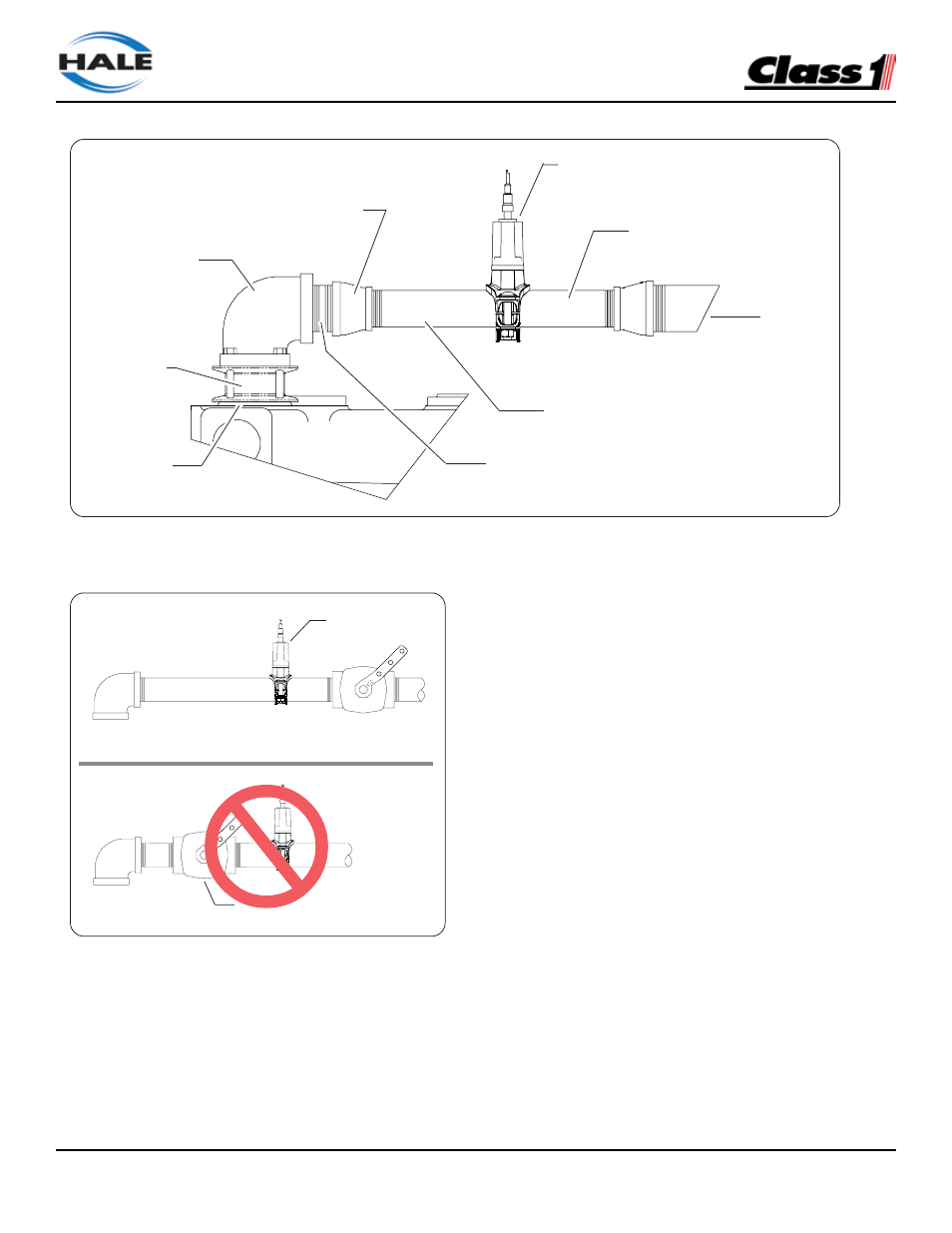

Figure 14: Typical Reduced Size Sensor Piping Arrangement

Figure 15: Flow Sensor Placement

3. Do not mount a flow sensor directly after

an elbow or valve. Valves create severe

turbulence when they are “Gated”.

Saddle Clamp Installation

See Figure 16: Flow Sensor/Saddle Clamp

Installation“ on page 40.

Installation of the Paddle Wheel Flow Sensor

using a saddle clamp requires a 1.385“/ 1.390“

(35/35.3mm) bored hole in the pipe.

A minimum of six times the pipe diameter of straight

run pipe without any fittings is neces sary prior to

the position of this hole.

The flow sensor requires a spacer and eight

stainless steel internal hex head screws. These

are supplied with the sensor.

Four 6-32 x 1/2“ screws attach the spacer to the

saddle clamp mount, and four 6-32 x 3/4“ screws

with lock washers attach the paddle wheel to the

spacer.