Class1 FoamLogix 2.1A & 1.7AHP REV D User Manual

Page 40

FoamLogix, Model 2.1A and 1.7AHP Class “A”

Electronic Foam Proportioning Systems

40

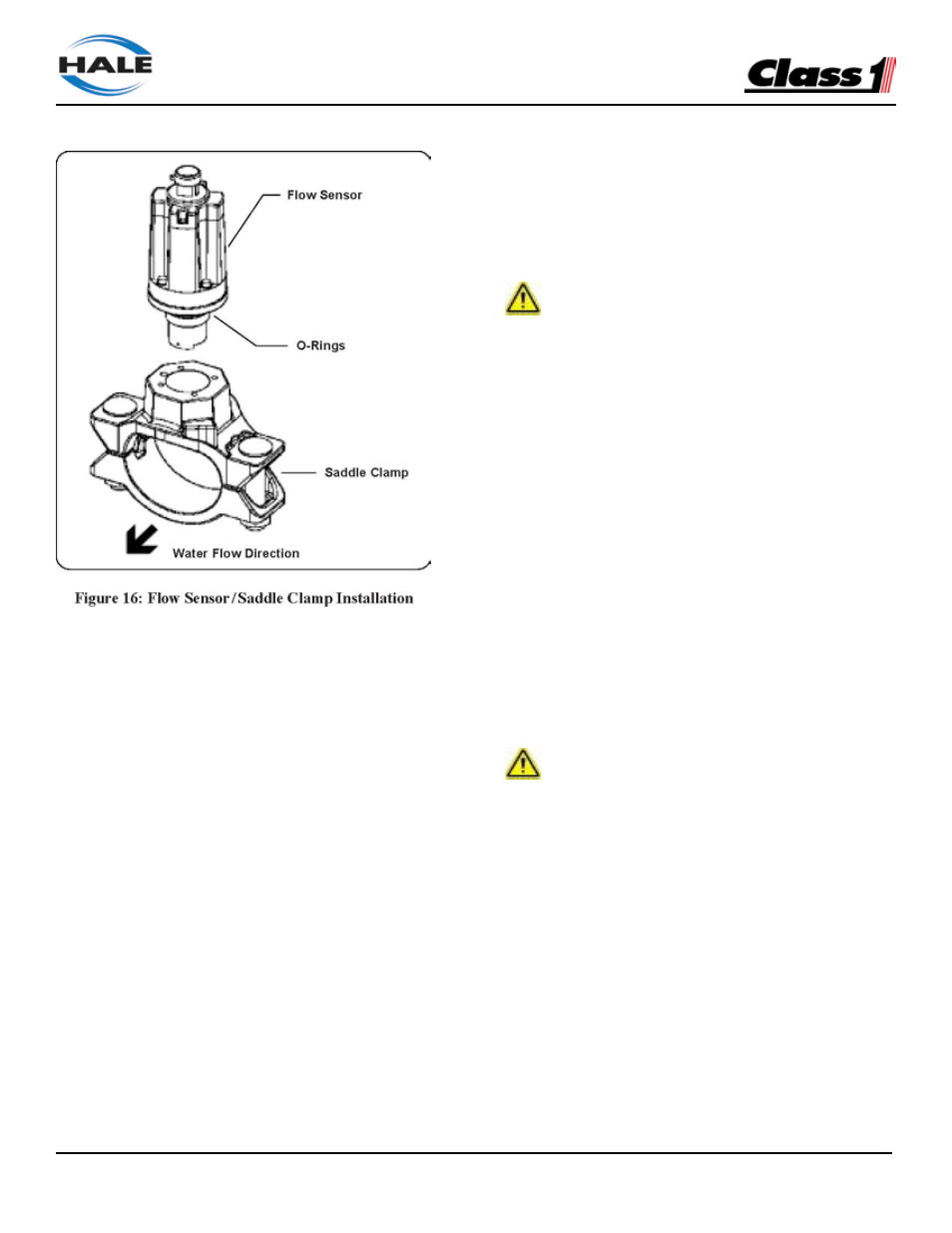

Align the indexing pin of the saddle clamp to the

indexing hole of the spacer to align the saddle

clamp mount.

Secure with four 1/2” machine screws, no lock

washers. Torque to 8.5 in.-lbs. (1.0 N-m).

Align the paddle wheel indexing pin to the indexing

hole in the spacer and secure using four 3/4”

screws and lock washers. Torque to 7.5 in.-lbs. (0.9

N-m).

Apply a small amount of grease to the saddle

clamp gasket before the final installation of the

assembly onto the pipe. Firmly tighten the saddle

clamp onto the pipe.

Foam Pump Flush System

The flushing water hose must be a minimum of 1/2”

(12 mm) inside diameter. The flush water supply

is provided from one of the pressure taps on the

discharge side of the fire pump.

It must be reduced to 50 PSI (3.5 BAR). It is

recommended to installed a check valve at the

pressure tap to prevent contamination.

FOAM CONCENTRATE PLUMBING

CAUTION!

MAKE SURE THE FOAM TANK AND FOAM CON-

CENTRATE SUCTION HOSES ARE CLEAN BE FORE

MAKING FINAL CONNECTION TO FOAM PUMP.

FLUSH TANK AND HOSES PRIOR TO MAKING

CONNECTIONS.

MAKE SURE THE FOAM CONCENTRATE IS

GRAVITY FED FROM THE TANK TO THE PUMP.

Foam concentrate plumbing consists of:

❑

Foam concentrate suction hose

❑

Foam strainer

❑

Foam concentrate discharge hose

❑

Check valve/injector fitting.

Foam Strainer Connection

CAUTION!

THE FOAM CONCENTRATE STRAINER ASSEM-

BLY, MOUNTED ON THE FOAM PUMP INLET, IS A

LOW PRESSURE DEVICE. IT WILL NOT WITH STAND

FLUSHING WATER PRESSURE. IF FLUSHING

WATER IS TO BE PROVIDED THE PRESSURE MUST

BE LIMITED TO 50 PSI (3.5 BAR).

The strainer/valve assembly has 1/2” (12mm) NPT

female threaded ports. A 1/2” hose barb fitting is

supplied to connect the 1/2” ID hose, provided with

the Hale Foam-Logix 2.1A installation kit.