Class1 FoamLogix 2.1A & 1.7AHP REV D User Manual

Page 41

FoamLogix, Model 2.1A and 1.7AHP Class “A”

Electronic Foam Proportioning Systems

41

Th

e hose from the foam tank to the strainer must

have adequate wall stiffness to with stand the

vacuum of the foam pump while it is operating (23”

[584 mm] Hg and 50 PSI [3 BAR], Kuriyama, Kuri-

tec K-3130 or K-7130 series or equal).

After the foam pump is mounted on the apparatus,

connect the PVC hose provided to the strainer inlet.

Install the clear plastic hose from the foam tank

outlet to the inlet of the strainer/valve assembly.

The inlet is on the valve end. Wetting the ends

of the hose and fittings makes the installation on

the hose fittings easier.

CAUTION!

MAKE SURE THE FOAM TANK AND FOAM CON-

CENTRATE SUCTION HOSES ARE CLEAN BE FORE

MAKING FINAL CONNECTION TO FOAM PUMP. IF

NECESSARY FLUSH TANK AND HOSES PRIOR TO

MAKING CONNECTION.

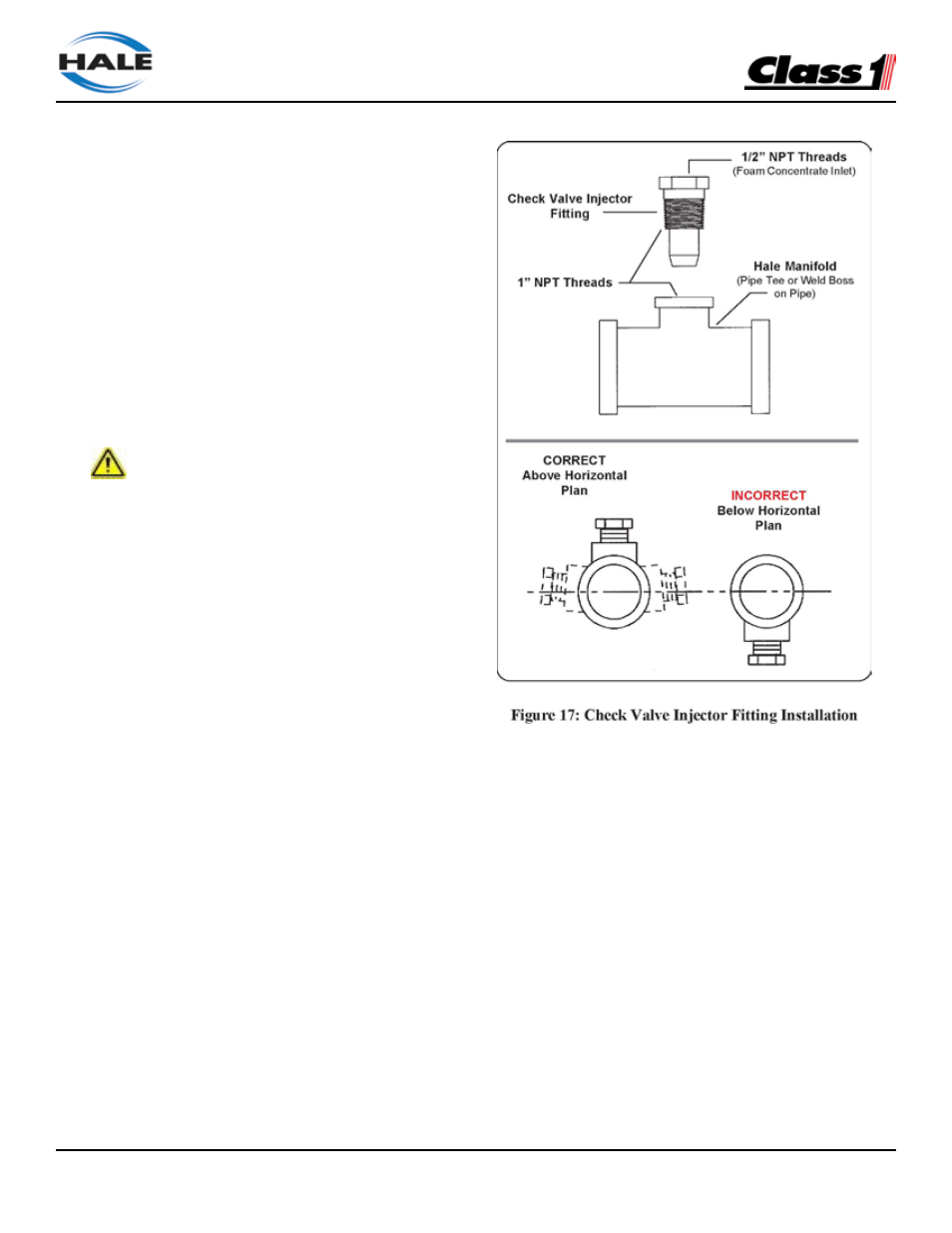

Check Valve/Injector Fitting

The Hale check valve/injector fitting, supplied

with the Hale FoamLogix system, meets NFPA

requirements for a non-return device in the foam

injection system. It prevents back flow of water into

the foam concentrate tank.

When properly installed the brass and stain-

less steel construction check valve/injector fitting

ensures foam concentrate is injected into the

center of the water flow for better mixing.

Note: Always position the check valve/ injector fitting

at a horizontal or higher angle to allow water to drain

away from the fitting. (See Figure 17: “Check Valve

Injector Fitting Installation.”) This avoids sediment

deposits or the formation of an ice plug.

The check valve/injector fitting MUST be mounted

in a location that is common to all discharges which

require foam concentrate. (See Figure 18: “Injection

and bypass Hose Connection”)

The Hale FoamLogix system DOES NOT permit

a separate injection point for each foam capable

discharge.

The check valve/injector fitting has – 1” NPT

(25.4mm) threads on the outside, to fit into the 1”

NPT threaded connection on the Hale mini manifold

a pipe tee, or a 1” NPT weld fitting installed in the

discharge piping of the fire pump. (See Figure 17:

“Check Valve Injector Fitting Installation.”)