System installer start-up, Initial system power check, Initial system check – Class1 FoamLogix 2.1A & 1.7AHP REV D User Manual

Page 49

FoamLogix, Model 2.1A and 1.7AHP Class “A”

Electronic Foam Proportioning Systems

49

System Installer Start-up

On initial power-up of the Hale FoamLogix system,

at the installer facility, the following procedures must

be followed.

INITIAL SYSTEM POWER CHECK

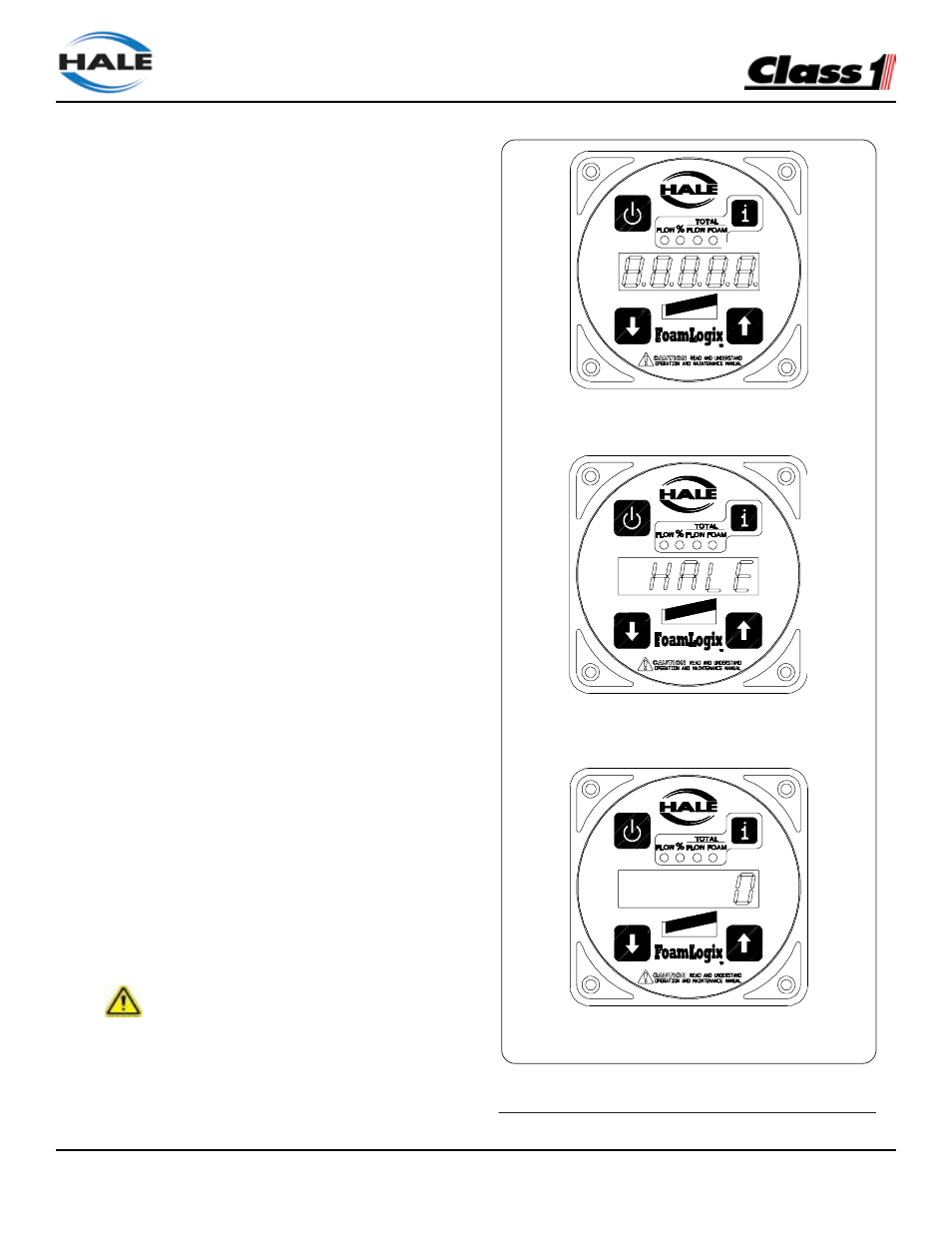

Watch the display on the control unit as the

apparatus electrical system is turned ON. Check

the control unit readout for:

❑

FLOW

❑

TOTAL FLOW

❑

% FOAM

❑

TOTAL FOAM

❑

all bar graph LEDs light

❑

“88888” appears for several seconds

❑

“HALE CLASS 1 2002” (or “HALE CLASS

1 [CURRENT DATE]”) scrolls across the

display

❑

The default display, zero (0), if no water is

flowing and FLOW LED

(See Figure 23: “Control Unit Ready Indication”)

If a default display does not appear, refer to Section

6: TROUBLESHOOTING for possible

WARM-UP/

SYSTEM CHECKING

causes and solutions.

INITIAL SYSTEM CHECK

After initial system power-up, low tank level sensor

operation, foam pump operation and flow sensor

calibration must be checked per the following:

CAUTION !

WATER IS USED AT THE SYSTEM INSTALLER

FACILITY TO VERIFY LOW TANK LEVEL SENSOR

SYSTEM READY

OPERATION AND FOAM PUMP

PERATION AS THE END USER SPECIFIED FOAM

CONCENTRATES MAY NOT BE READILY AVAILABLE.

FOAMLOGIX, Model 2.1A Class "A"

47

Electronic Foam Proportioning System

Installation

ISO 9001 CERTIFIED

SYSTEM INSTALLER START-UP

On initial power-up of the Hale FoamLogix

system, at the installer facility, the following

procedures must be followed.

INITIAL SYSTEM POWER CHECK

Watch the display on the control unit as the

apparatus electrical system is turned ON. Check

the control unit readout for:

❑

FLOW

❑

TOTAL FLOW

❑

% FOAM

❑

TOTAL FOAM

❑

all bar graph LEDs light

❑

“88888” appears for several seconds

❑

“HALE CLASS 1 2002” scrolls across the

display

❑

The default display, zero (0), if no water is

flowing and FLOW LED

(See Figure 23: “Control Unit Ready

Indication”).

If a default display does not appear, refer to

Section 6: TROUBLESHOOTING for possible

causes and solutions.

INITIAL SYSTEM CHECK

After initial system power-up, low tank level

sensor operation, foam pump operation and flow

sensor calibration must be checked per the

following:

CAUTION!

WATER IS USED AT THE SYSTEM INSTALLER

FACILITY TO VERIFY LOW TANK LEVEL SENSOR

OPERATION AND FOAM PUMP OPERATION AS

THE END USER SPECIFIED FOAM CONCEN-

TRATES MAY NOT BE READILY AVAILABLE.

Figure 23: Control Unit Ready Indication

SYSTEM READY

WARM-UP/SYSTEM CHECKING

INITIAL POWER-UP