Operation, Description – Class1 FoamLogix 2.1A & 1.7AHP REV D User Manual

Page 59

FoamLogix, Model 2.1A and 1.7AHP Class “A”

Electronic Foam Proportioning Systems

59

Section 4 Operation

DESCRIPTION

Operation of Hale FoamLogix systems is con trolled

by the Digital Display Control Unit, pro vided with

four push buttons (pads). (See Figure

36: “Digital Diaplay Control Unit Overview.”)

The Hale FoamLogix system constantly monitors

water and foam concentrate flow values, main taining

foam injection at the specified concentrate injection

rate. The system responds to variations in water flow

by increasing or decreasing the speed of the foam

pump.

On initial power up of the apparatus, the Hale

FoamLogix system begins a brief self-diagnostic

routine. When completed, the system enters the

STANDBY mode. The

FLOW LED lights and the

dsiplay shows the current water flow rate in the

monitored discharge pipe.

Pressing the DISPLAY button (i) cycles through

the four functions as indicated by the red LED

illuminating under each function.

Note: TOTAL FLOW and TOTAL FOAM values

may be reset any time they are displayed. When

the

% FOAM LED is lit, or in any other function

mode, the foam concentrate injection rate may

be set to the desired value, if different from the

default value. This may be adjusted prior to or

during foam operations by pressing the and

buttons. Also see heading “Control unit functions”

on page 60.

When the red

ON button is pressed, the FLOW

LED illuminates indicating that the system is

ready. If water flow is present the foam pump

starts and injects foam concentrate into the

discharge stream.

The bar graph lights when foam is being injected

and indicates system capacity.

When the

ON button is pressed again the LEDs

extinguish, indicating that the system is in STANDBY

mode and the foam pump STOPS. However, other

system monitoring functions continue.

FOAMLOGIX, Model 2.1A Class "A"

57

Electronic Foam Proportioning System

Operation

ISO 9001 CERTIFIED

Note: TOTAL FLOW and TOTAL FOAM

values may be reset any time they are

displayed. When the

% FOAM LED is lit, or in

any other function mode, the foam

concentrate injection rate may be set to the

desired value, if different from the default

value. This may be adjusted prior to or during

foam operations by pressing the and

buttons. Also see heading “Control unit

functions” on page 58.

When the red

ON button is pressed, the FLOW

LED illuminates indicating that the system is

ready. If water flow is present the foam pump

starts and injects foam concentrate into the

discharge stream.

The bar graph lights when foam is being injected

and indicates system capacity.

When the

ON button is pressed again , the LEDs

extinguish, indicating that the system is in

STANDBY mode and the foam pump STOPS.

However, other system monitoring functions

continue.

SECTION

4

OPERATION

DESCRIPTION

Operation of Hale FoamLogix systems is con-

trolled by the Digital Display Control Unit, pro-

vided with four push buttons (pads). (See Figure

36: “Digital Diaplay Control Unit Overview.”)

The Hale FoamLogix system constantly monitors

water and foam concentrate flow values, main-

taining foam injection at the specified concentrate

injection rate. The system responds to variations

in water flow by increasing or decreasing the

speed of the foam pump.

On initial power up of the apparatus, the Hale

FoamLogix system begins a brief self-diagnostic

routine. When completed, the system enters the

STANDBY mode. The

FLOW LED lights and the

dsiplay shows the current water flow rate in the

monitored discharge pipe.

Pressing the DISPLAY button (

i ) cycles through

the four functions as indicated by the red LED

illuminating under each function.

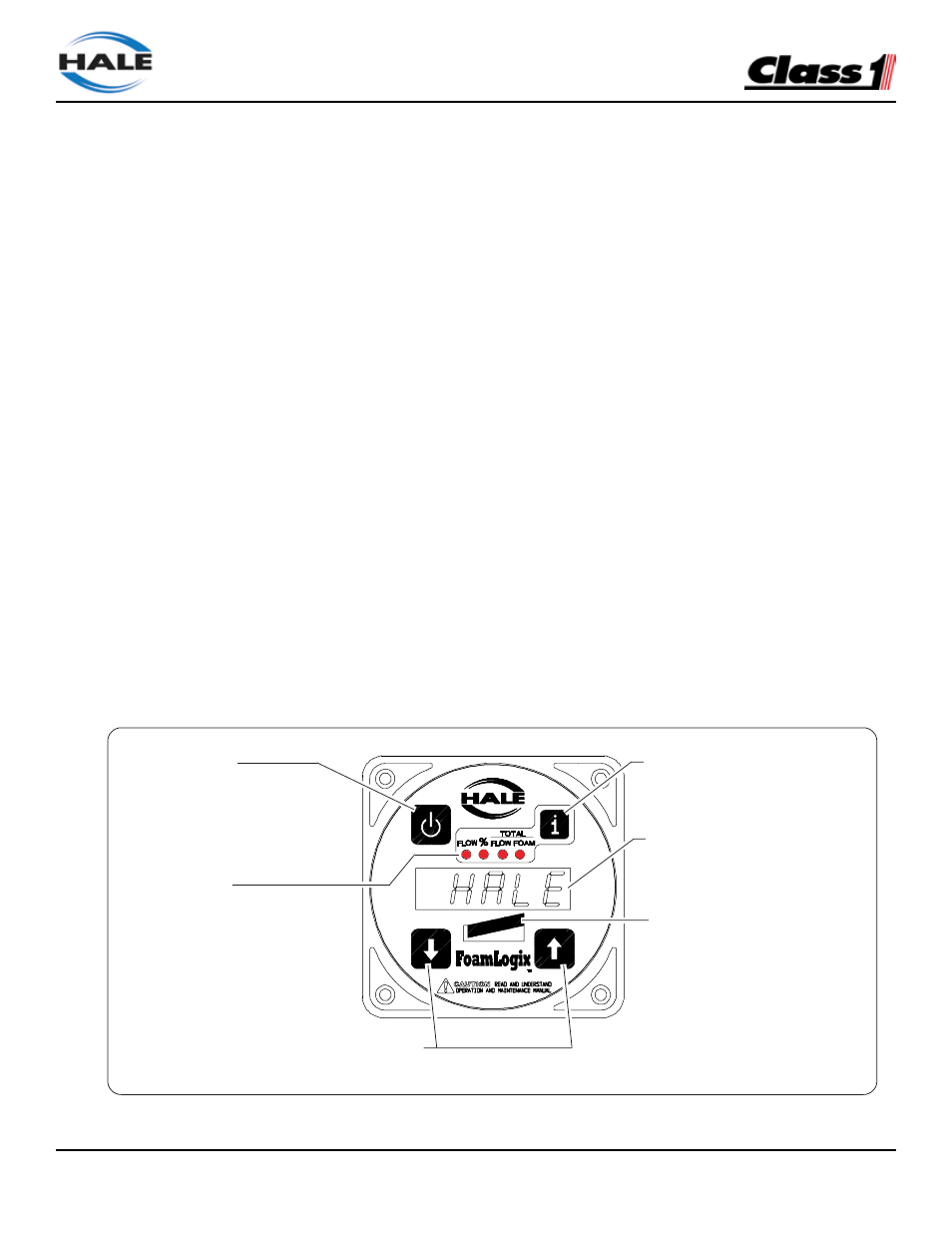

Figure 36: Digital Display Control Unit Overview

SELECT DISPLAY

(Selects control unit function as indicated

by labels and LEDS to the left.)

LED Indicators (4)

(Light ot indicate the function selected.)

On /OFF BUTTON

(Turns Foam Injection ON or OFF.)

BAR GRAPF

(Lights to indicate the system is ON and

the level of injected foam concentrate.)

UP/DOWN ARROWS

(Used to adjust the concentrate injection rate during operation. Pressing both

arrows simultaneously resets the TOTAL FOAM or FLOW Values.)

DIGITAL DISPLAY

(Provides direct readout of selected

function values and shows WARNINGS.)

Figure 36: Digital Display Control Unit Overview