Normal operation summary – Class1 FoamLogix 2.1A & 1.7AHP REV D User Manual

Page 64

FoamLogix, Model 2.1A and 1.7AHP Class “A”

Electronic Foam Proportioning Systems

64

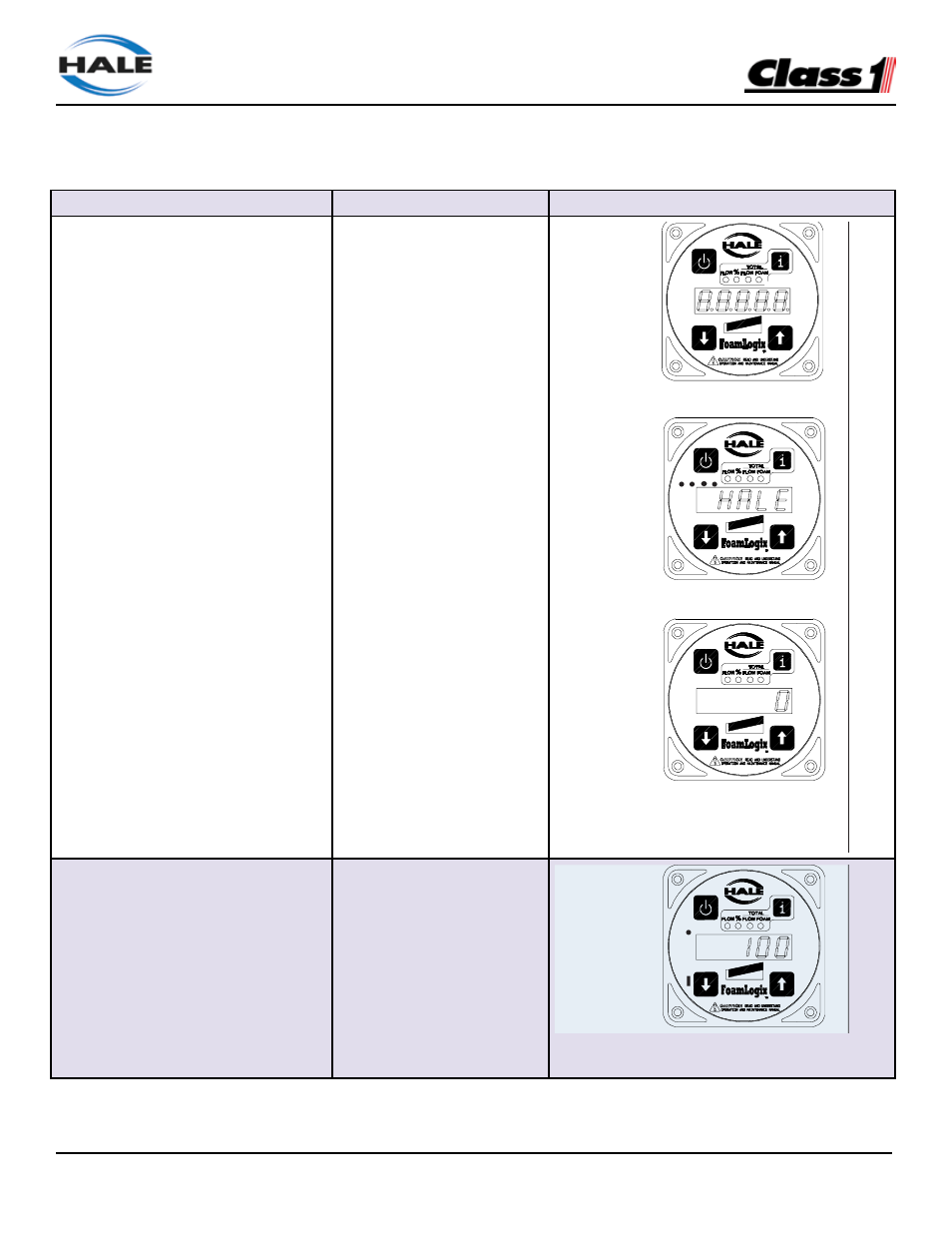

NORMAL OPERATION SUMMARY

OPERATION

ACTION

DISPLAY

Energize the system

Select foam tank

Energize apparatus and

turn FoamLogix power

switch to

ON.

If System equipped with

dual foam tanks place

selector toproper tank.

62

FOAMLOGIX, Model 2.1A Class "A"

Electronic Foam Proportioning System

Operation

ISO 9001 CERTIFIED

NORMAL OPERATION SUMMARY

OPERATION

ACTION

DISPLAY

Begin foam injection

Energize the system

Select foam tank

Energize apparatus and turn

FoamLogix power switch to

ON.

Initial StarUp

Self Diagonstics

STANDBY Display

(Single Flow Sensor: FLOW MULTIPLE

Flow Sensor: % FOAM)

If System equipped with dual

foam tanks place selector to

proper tank.

Water Flow

Established

(ON Button Pressed)

Establish water flow and press

ON button.

Begin foam injection

Establish water flow and

press

ON button.

62

FOAMLOGIX, Model 2.1A Class "A"

Electronic Foam Proportioning System

Operation

ISO 9001 CERTIFIED

NORMAL OPERATION SUMMARY

OPERATION

ACTION

DISPLAY

Begin foam injection

Energize the system

Select foam tank

Energize apparatus and turn

FoamLogix power switch to

ON.

Initial StarUp

Self Diagonstics

STANDBY Display

(Single Flow Sensor: FLOW MULTIPLE

Flow Sensor: % FOAM)

If System equipped with dual

foam tanks place selector to

proper tank.

Water Flow

Established

(ON Button Pressed)

Establish water flow and press

ON button.