Calibration, Color calibration method – Konica Minolta bizhub PRO C6500P User Manual

Page 146

138

Chapter 7—Color Workflow

Calibration

One of the most important issues in obtaining satisfactory print

quality is steady toner density. Toner density is affected by many

factors such as heat, humidity, and service settings. You should

perform calibration every 24 hours to compensate for these

factors.

The calibration process corrects the printer colors by measuring

their density and creating calibration look-up tables. The IC-304

print controller uses the data in these tables to compensate for the

differences between the actual, measured density level and the

target level, the target density.

You should perform calibration in the following instances:

•

When prints show “color casts”

•

After machine maintenance or hardware changes—for

example, replacing a “Charge Coroton”

•

On drastic ambient changes (temperature and humidity)

Color Calibration Method

The IC-304 print controller uses the target calibration method. This

method ensures consistency over time and that the density values

of the printed output do not exceed the predefined density values.

Target calibration enables you to calibrate the printer according to

the following predefined density values:

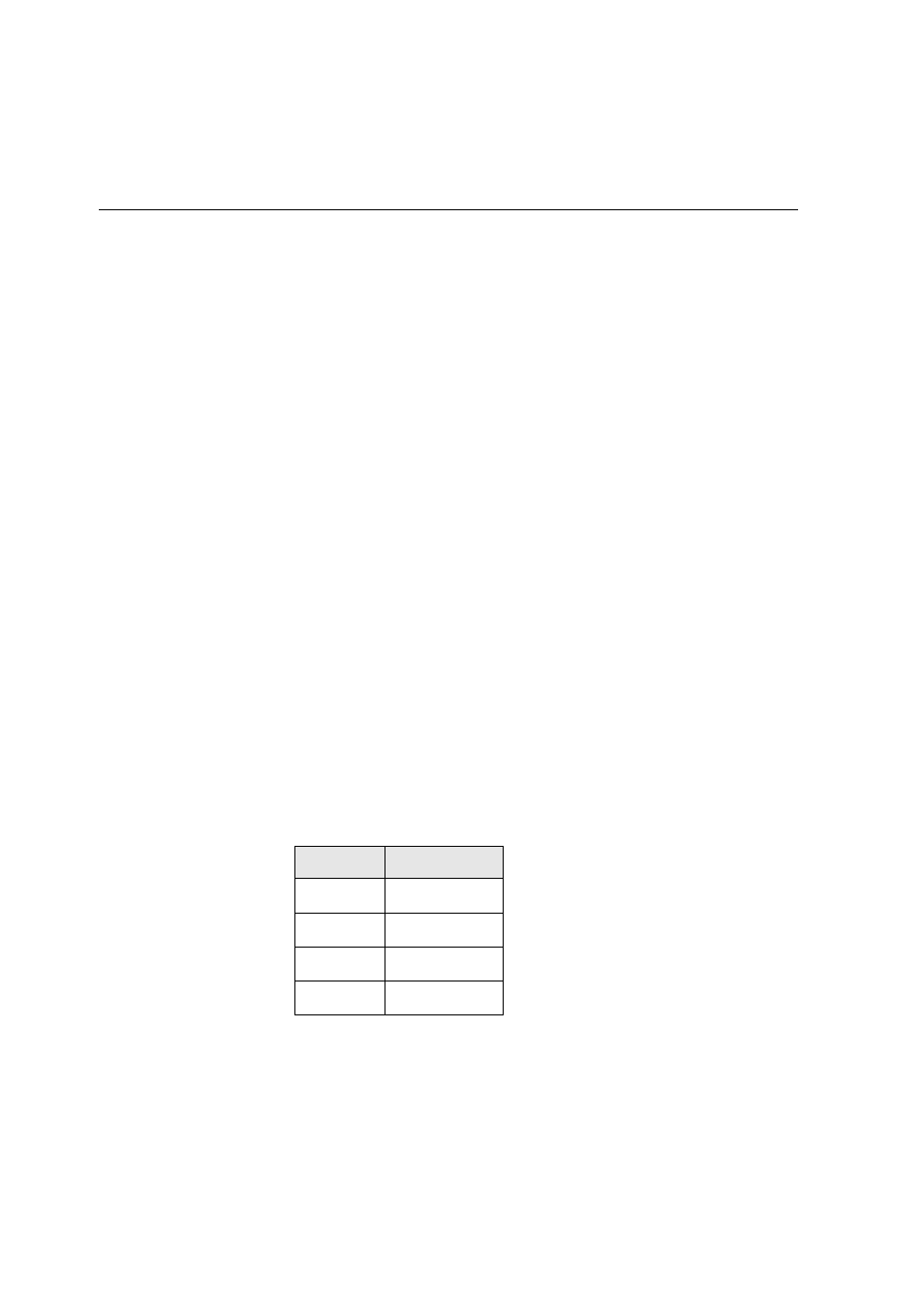

Table 11: Fixed density values for uncoated paper

Toner

Density value

Cyan

1.3426

Magenta

1.4669

Yellow

0.9246

Black

1.7603