Drying time – RADWAG MA 200.3Y Moisture Analyzer User Manual

Page 71

- 71 -

place at full power of the filaments, causing heating the drying chamber to

increased temperature (maximum temperature value is higher by 30 % from

set drying temperature). Overheating compensates heat loss during

evaporation of large moisture content in the test’s initial stage.

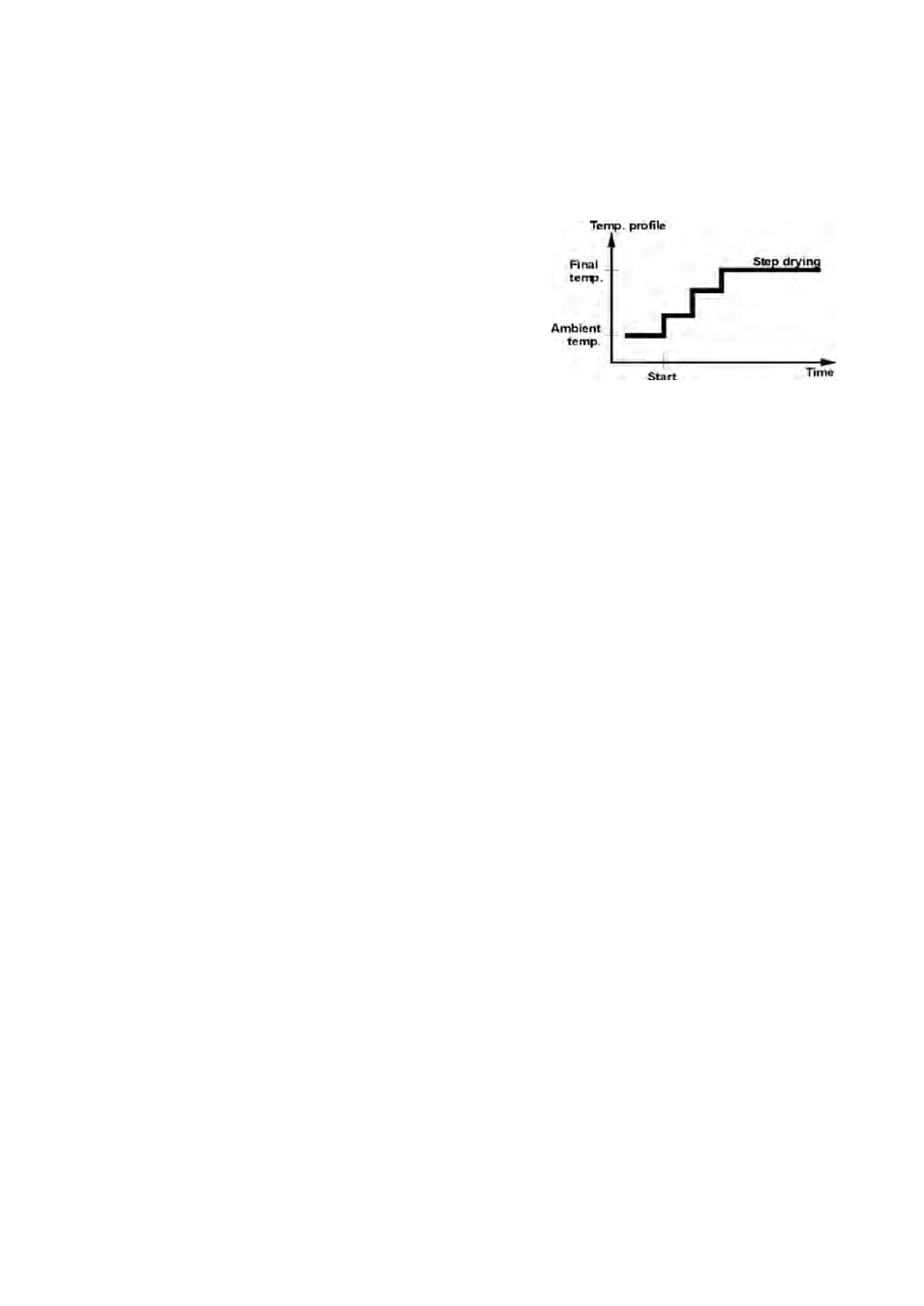

STEP mode

Enables determining up to three steps with

random drying temperature. Step mode is

recommended for drying substances with

moisture content over 15%. Temperature and

heating time in each step have to be adjusted

by tests.

17.2.5. Drying time

Drying time is set by selecting one of available finish mode criteria. This

means that a moisture analyzer must meet pre-set criterion (one of the

requirements: mass over time, time) to automatically finish the drying mode.

Finish of drying process can be triggered by amount of time, independently on

loss in mass. This criterion is used for substances that may decompose during

drying process, and their mass does not reach constant value.

The second criterion is loss in mass (less than 1 mg) in defined amount of

time.

Automatic finish mode (Auto switch off mode)

MA 3Y operator can choose between various types of finish modes:

-

Automatic 1 (change 1mg/10s)

-

Automatic 2 (change 1mg/25s)

-

Automatic 3 (change 1mg/60s)

-

Automatic 4 (change 1mg/90s)

-

Automatic 5 (change 1mg/120s)

-

Time defined (maximum drying time 99 hours 59 minutes)

-

Manual (on pressing a function key)

-

User defined 1 (set mass change ratio ∆m 0,1-9,9mg and time interval ∆t

max 2,55 sec.

-

User defined 2 (set moisture content change ratio ∆%M over time 60s)

-

Test (enables adjusting finish mode parameters to a tested sample)

Automatic finish mode – user defined criterion (mass/time)

MA 3Y operator determines the limit value for loss of mass and time in which

the loss of mass must not exceed a pre-set value. As the moisture analyzer

reaches the set criterion it automatically finishes the measurement (drying

process).