Drying temperature – RADWAG MA 200.3Y Moisture Analyzer User Manual

Page 69

- 69 -

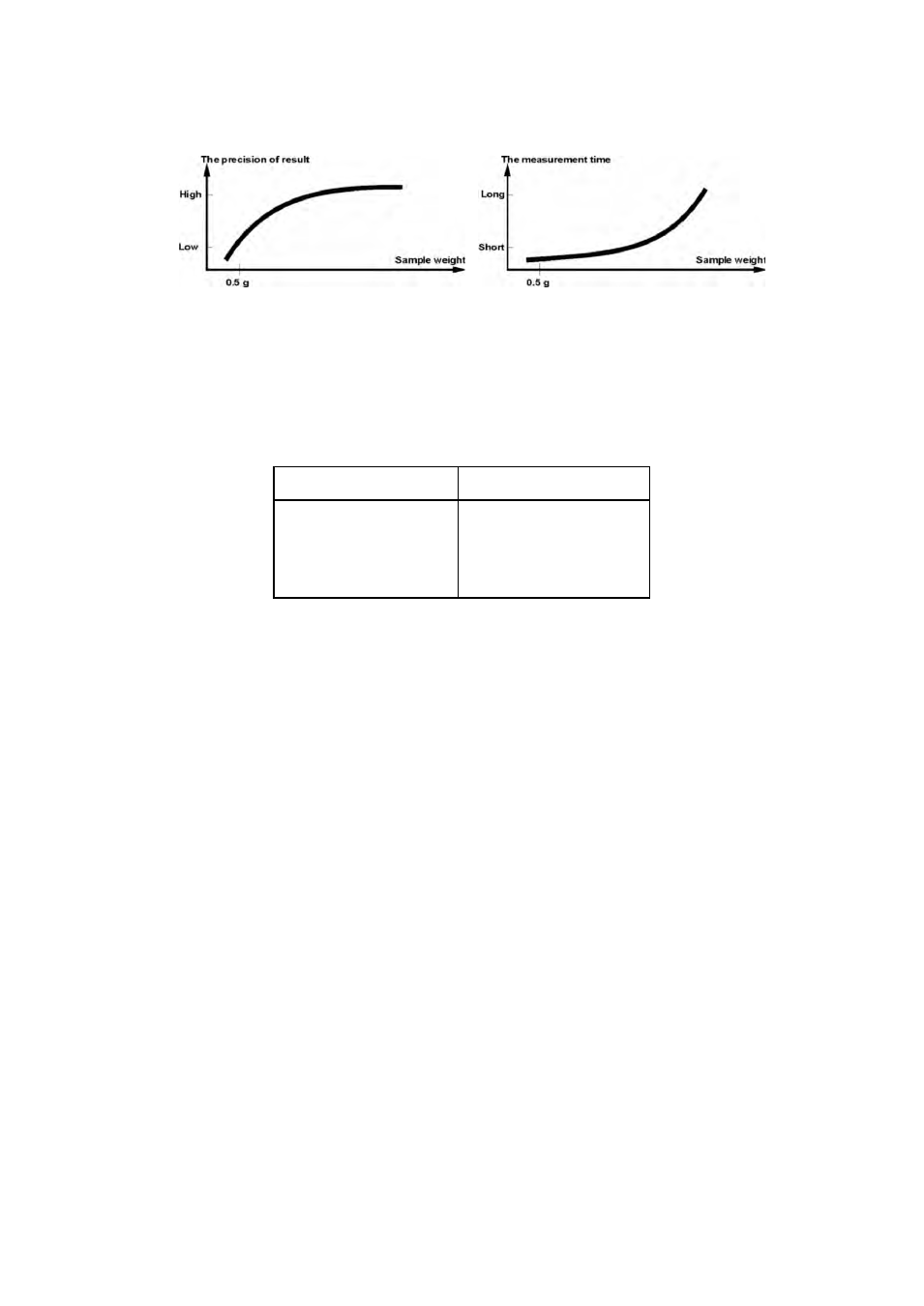

Obtaining short measurement time is feasible in case of small sample mass,

but sample mass cannot be too small, as it may negatively influence required

measurement accuracy.

17.2.2. Influence of sample mass on measurement result repeatability

Sample mass has considerable influence on repeatability of measurement

results obtained on a moisture analyzer. Relation between sample mass and

repeatability is presented in below table.

Sample mass

Repeatability

to 2g

±

0,24%

to 10g

±

0,06%

Over 10g

±

0,04%

Data provided in the above table refer to an ideal and uniform sample, and an

assumption, that moisture content has completely evaporated from tested

sample during testing process, and the sample has not decomposed (e.g.

humid high-silica sand).

Measurement results are always subject to uncertainty related to a sample

and repeatability of used moisture analyzer. In practice, it means that

obtained measurement result may exceed repeatability values provided above.

17.2.3. Drying temperature

Drying temperature has the largest impact on drying time. Temperature value

depends on type of dried substance. Too low drying temperature causes too

low moisture content evaporation (under-dried sample), and consequently

unnecessary extending of measurement time. Too high drying temperature

causes burning of dried sample (sample overheating, chemical

decomposition). Drying temperature of traditional method (using a furnace) is

specified in applicable industry or company standards. Unless standards apply,

then temperature should be adjusted by tests.

On selecting drying temperature value, proceed as follows:

•

Determine moisture content in a sample

•

Determine temperature of substance chemical decomposition by tests