2 mpc vector standard features – Pulsafeeder MPC Vector User Manual

Page 8

2

The motor used with the MPC VECTOR is a three-phase motor; however the three-phase power is generated

internally by the MPC VECTOR itself. Do not be confused by the motor nameplate. Input power to the

MPC VECTOR is single-phase or three-phase AC 230 volts (see Section 12, Specifications for acceptable

voltage range). The nameplate on the side of your MPC VECTOR controller will list the appropriate supply

requirements for your controller.

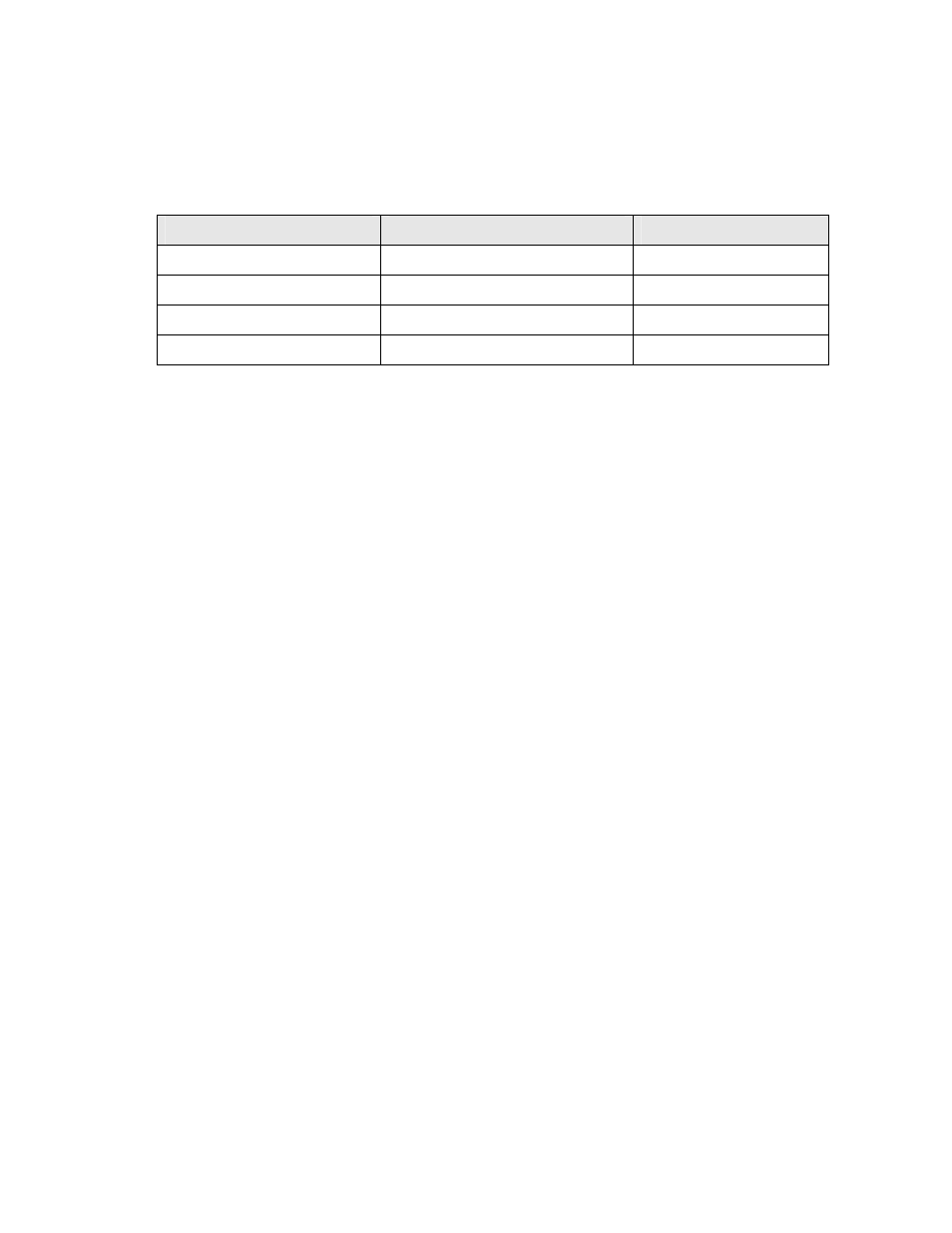

Motor Hp Rating

MPC VECTOR Input Power*

Output to Motor**

1

208/230 VAC 1 or 3 phase

230 VAC 3 phase

2

208/230 VAC 1 or 3 phase

230 VAC 3 phase

3

208/230 VAC 1 or 3 phase

230 VAC 3 phase

5

208/230 VAC 3 phase only

230 VAC 3 phase

* all input ratings are 50 or 60 Hz

** output to pump motor is always 60 Hz maximum frequency

The AC drive used in the MPC VECTOR maintains tight control over voltage and current supplied to the

pump motor. This results in lower motor operating temperatures and less stress on motor windings, resulting

in longer motor life and more reliable overall operation. Further motor selection information can be found in

Section 12, Specifications at the end of this manual.

1.2 MPC VECTOR Standard Features

• User keypad and display for ease of operation

• Display pump operation in GPH, LPH, GPM, LPM, or RPM

• One 4-20 mA analog input signal for flow control

• One analog (mA) input for flow feedback control (with an external, user supplied flow metering device

which provides an analog signal)

• Sensorless vector motor speed control

• Two configurable digital inputs

• Three configurable digital outputs (transistor type, 40 VDC maximum)

• Analog 4-20 mA feedback output

• NEMA 4X and IP56 ratings (for controller housing)

• 230 Volts, 50 or 60 Hz, single or three phase AC power for 1 through 3 Hp systems

• 230 Volts, 50 or 60 Hz, three phase (only) AC power for 5 Hp systems

• Security code lockout of menus

• Standard configurable pump protection utilizing proprietary PulsaGuard technology