Motor selection and requirements, General specifications, Turndown requirements – Pulsafeeder MPC Vector User Manual

Page 52

46

Motor Selection and Requirements

General Specifications

All motors used with the MPC VECTOR controller must meet these minimum specifications:

•

230 VAC, 50 or 60 Hz 3-phase input power AC induction motor

•

1800 rpm (60 Hz) or 1500 rpm (50 Hz) synchronous speed

•

Service Factor 1.05 or greater

•

Class F Insulation (minimum)

•

Refer to your equipment specifications and documentation for the correct frame size

•

Motors may or may not need feet and/or a C-face mount depending on equipment

Turndown Requirements

Motor turndown ratings are dependent on the application and intended use of the pump. Users should understand and

take into account the following factors when considering motor selection:

•

Application required turndown ratio

•

Viscosity of pumped liquid

•

Length of wiring between the MPC VECTOR controller and the pump (motor)

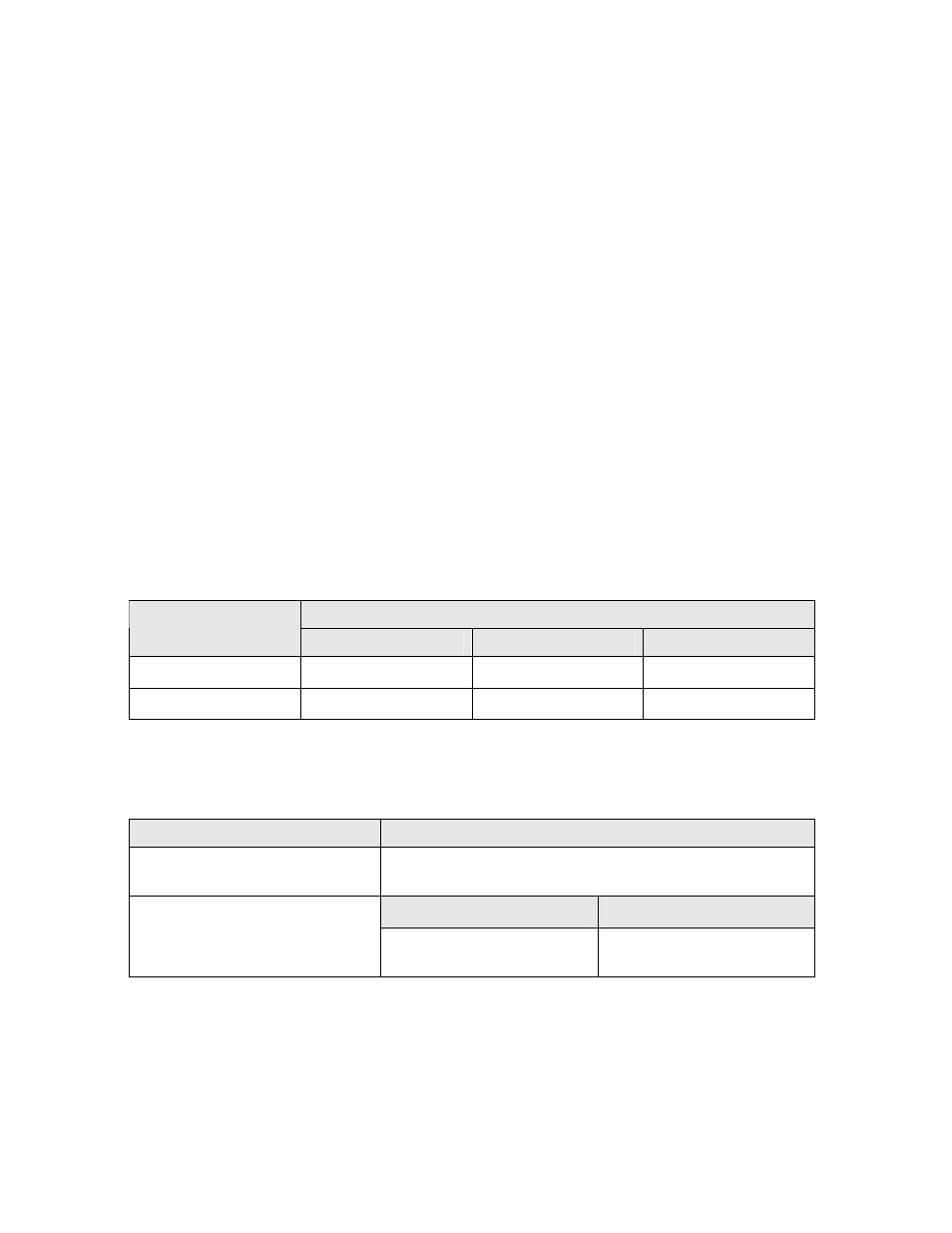

Application Required Turndown Range

Liquid Viscosity

4:1

10:1

20:1

Low, below 50 CPS

3:1 or 4:1

N/A

(see note below)

Consult factory

High, above 50 CPS

3:1 or 4:1

10:1

Consult factory

NOTE: when pumping liquids with low viscosity, pump performance is greatly diminished at slow rotational speeds due

to internal slip. Therefore, high speed turndown ratios are not expected in this type of application.

Cable Length

Minimum Required Motor Turndown Rating

MPC VECTOR to motor less than 25

feet (7.6 meters)

Use ratings guidelines in chart above

4:1 or 10:1 turndown

20:1 turndown

MPC VECTOR to motor greater

than 25 feet (7.6 meters)

Must use 10:1 inverter duty

rated motor

Consult factory

NOTE: the maximum pump to controller distance is 100 feet (30.5 meters). If longer distances are required, please

contact the factory. Line and load reactors can be utilized to allow operation over longer distances.