Introduction, 1 description – Pulsafeeder MPC Vector User Manual

Page 7

1

1. Introduction

The MPC VECTOR is a microprocessor based motor speed control device, for use with Pulsafeeder pumps. It has

been designed for simplicity, yet still has many advanced features that allow the MPC VECTOR to operate in a wide

variety of environments and applications. This product is not just a variable speed drive. It is a state of the art

multifunctional controller, which provides functionally no one stand-alone variable speed drive does. What makes this

product unique is that it combines functionality of three devices in one:

• Vector type variable speed drive.

• Input output processor (4-20 mA in and out, digital input/output), including PID loop for closed loop flow

control.

• Power monitor for detection of run-dry conditions

This instruction manual covers the MPC VECTOR control only. For information and safety precautions specific to the

pump or any other accessories, please refer to the appropriate IOM.

1.1 Description

The MPC VECTOR is an advanced pump controller that is physically separated from the pump's enclosure. Its

purpose is to precisely adjust output flow of a process media by means of pump motor speed control.

The MPC VECTOR is designed for a wide variety of control applications. If delivered with a pump and motor,

the device is factory configured. Field configuration may be required in certain installations. Local setup and

control is achieved through the keypad and a backlit two-line liquid crystal display. Basic operation is simple with

dedicated function keys eliminating the need for a sophisticated menu system. Pump output is displayed as

Gallons or Liters per Hour (GPH/LPH), Gallons or Liters per Minute (GPM/LPM), or Revolutions per Minute

(RPM).

Digital and analog inputs will support a variety of industry standard signals to offer flexible remote control.

The MPC VECTOR is designed to simplify and automate the calibration of pump flow and analog signals. Flow

calibration uses on-screen prompting and automated pump operation to eliminate stopwatches, calculators and

human inaccuracies. Analog signal calibration is also accomplished by simple keypad entry. It includes a real-

time display of signal level. This eliminates the need for external meters.

The MPC VECTOR will accept, and automatically adjust to, either 60 Hz or 50 Hz input power. No special

modifications, settings, or adjustments are required. MPC VECTOR controller can be supplied with a 60 Hz, 50

Hz, or dual rated 50/60 Hz motor. The controller/motor combination allows for 60 Hz rated pump flow (1800 rpm

motor speed) even when operating from a 50 Hz input. Users in locations with 50 Hz AC supply do not have to

de-rate pump flow with this controller.

Minimum motor speed is limited under all circumstances to 31 rpm. Please note that in certain applications, the

practical minimum speed (to achieve flow and pressure) may be higher than 31 rpm. This can be dependent

on product viscosity and other application-specific variables.

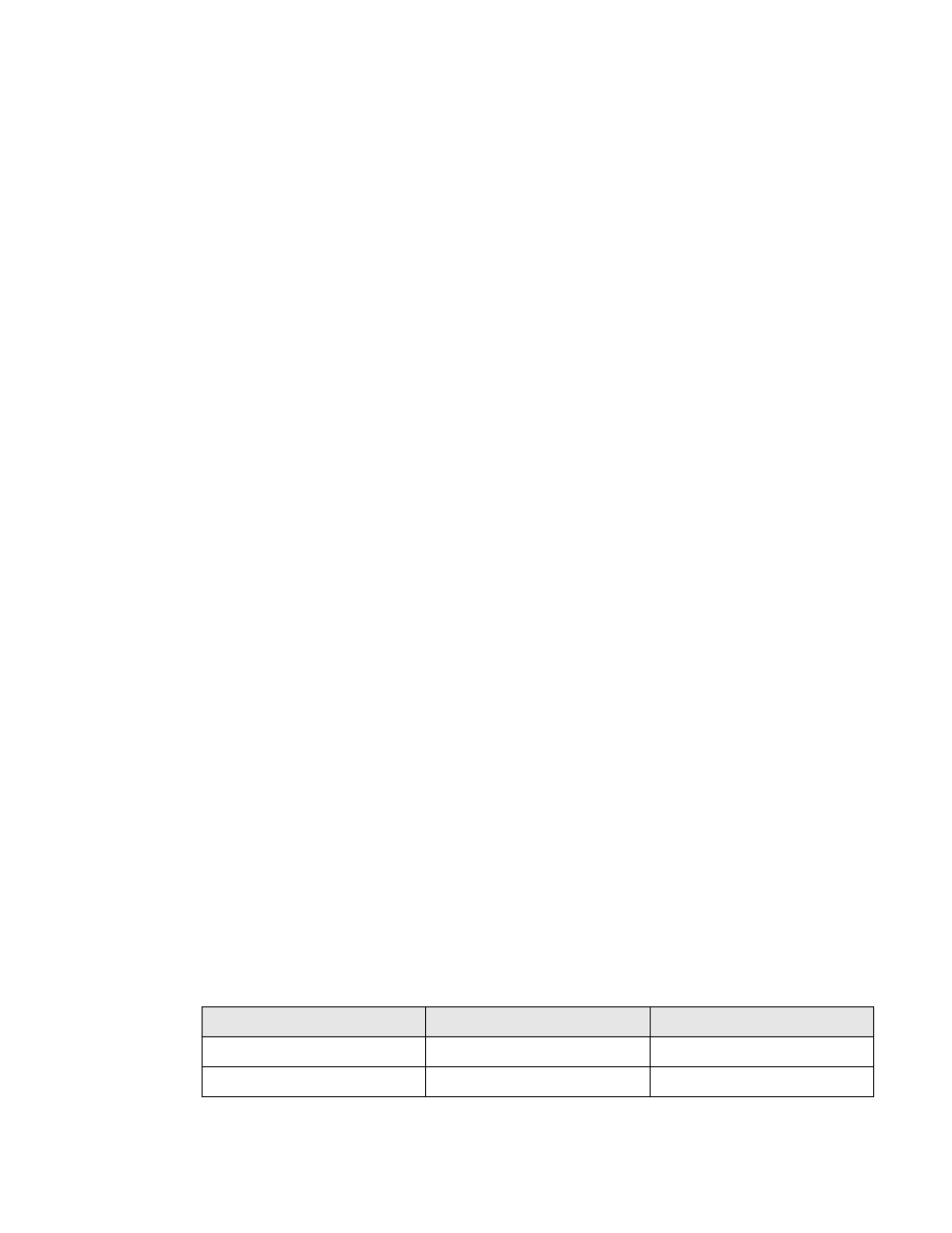

Input Frequency

MPC VECTOR Motor

Max MPC VECTOR Output

60 Hz (USA and similar)

60 Hz (or dual rated)

60 Hz / 1800 rpm

50 Hz (Europe, Asia, etc)

50 Hz or 60 Hz or dual rated

60 Hz / 1800 rpm