7 timeout monitoring – NORD Drivesystems BU0290 User Manual

Page 36

PROFINET bus module for NORD frequency inverters SK 200E

36

Subject to technical amendments

BU 0290 GB-4312

5.1.6

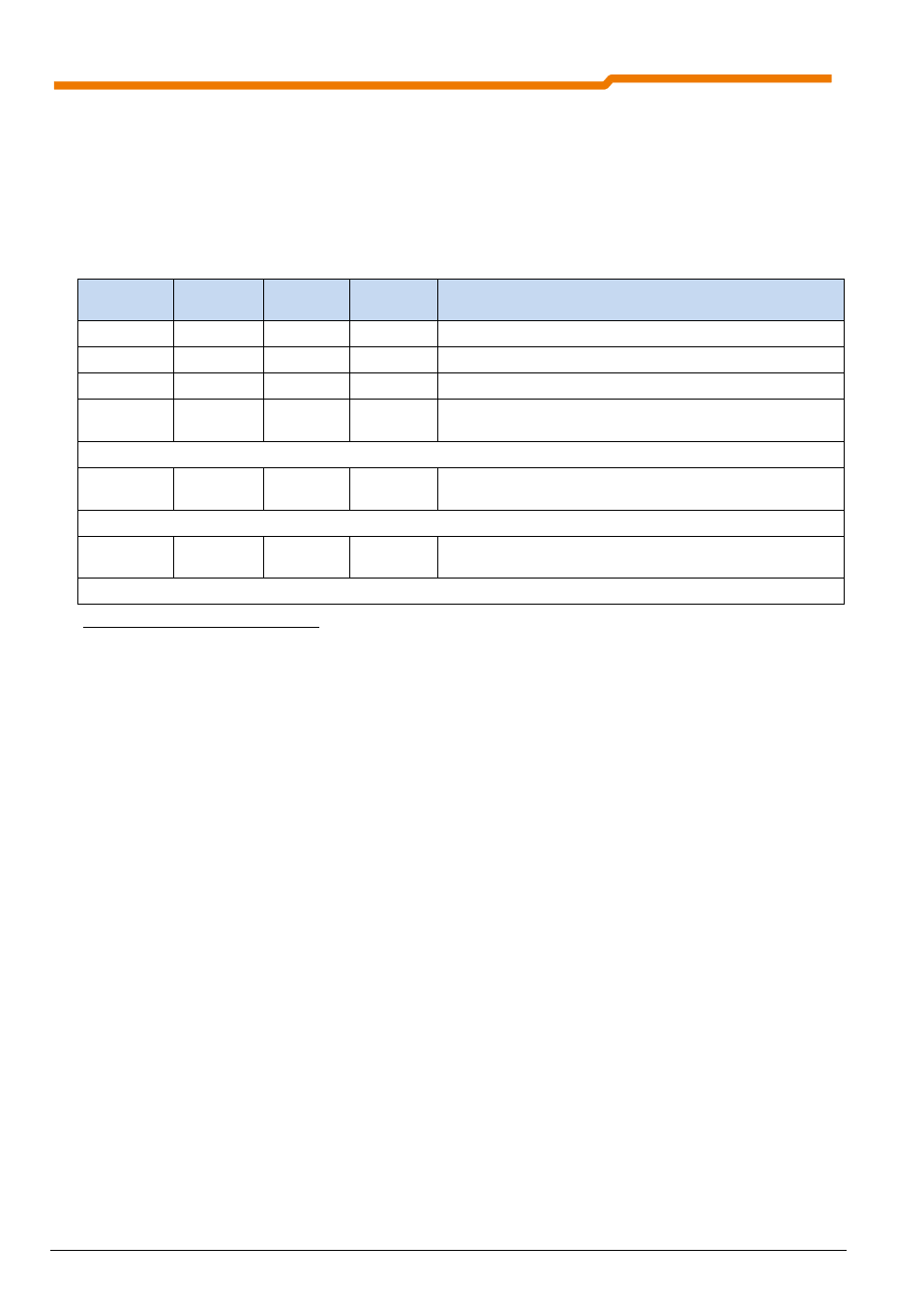

Example for switching the frequency inverter on and off

In this example, a frequency inverter will be operated with a setpoint (setpoint frequency) and an actual value

(actual frequency). The "Maximum Frequency" is 50Hz.

Parameter settings:

P105 = 500

P543 = 1

P546 = 1

Control

word

Setpoint 1

Status

word

Actual

value 1

Explanation

- - -

- - -

0000h

0000h

- - -

- - -

xx40h

0000h

The mains voltage is switched on at the FI

047Eh

0000h

xx31h

0000h

FI is set to "Standby" status

047Fh

2000h

xx37h

2000h

FI is set to "Operation enabled" status and controlled with a

50% setpoint.

The FI is enabled, the motor is supplied with current and rotates with a frequency of 25Hz.

0047Eh

2000h

xx31h

0000h

FI is set to "Standby" status, the motor runs up its

parameterised ramp to speed 0 and is switched off.

The FI is disabled again and the motor is without current.

047Fh

1000h

xx37h

1000h

FI is set to "Operation enabled" status and controlled with a

25% setpoint.

The FI is enabled, the motor is supplied with current and rotates with a frequency of 12.5Hz.

Table 20 Example of setpoint specification

5.1.7

Timeout monitoring

The PROFINET IO data traffic can be monitored with a watchdog with the aid of the time set in parameter

P151. If no further cyclical data is sent from the PROFINET IO controller, a module error is detected and set in

the FI (E10.3).

Monitoring via the FI parameter P513 is also possible. This is triggered if the process data contact is

interrupted or the process data is transferred with an invalid control word (Bit10 in control word = 0). This

function is activated when the first valid process data telegram is received.