Clincher™ ordering guide, Product specifications – NORD Drivesystems B1000 User Manual

Page 9

www.nord.com

A7

G1000 – Subject to Change Without Notice

N

OI

T

C

U

D

O

RT

NI

Gear Unit

Shaft/Mounting

Reducer Options

Motor/Input

Motor Options

SK

-

see page 816

see page 816

Gear Unit

0182NB 1382NB 1282/02 6382/22

0282NB

2382

2282/02 6382/32

1282

3382

3282/12 7382/22

2282

4382

4282/12 7382/32

3282

5382

5282/12 8382/22

4282

6382

8382/32

5282

7382

9382/42

6282

8382

9382/52

7282

9382

10382/52

8282

10382

11382/52

9282

11382

10282

12382

11282

Clincher™

Ordering Guide

Shaft/Mounting

VZ - Solid Shaft/B14 Flange

VX - Solid Shaft/Foot

AZ - Hollow Shaft/B14 Flange

VF - Solid Shaft/B5 Flange

LX - Double Solid Shaft/Foot

AF - Hollow Shaft/B5 Flange

SCP - Screw Conveyor Package

AX - Hollow Shaft/Foot

Reducer Options

B - Fixing Kit

LL - Long Term Storage

Cross Drilled Shaft

G - Rubber Buffers

VL - Heavy Duty Output Bearings FKM - Fluoro-rubber Seals

VG - Heavy Duty Rubber Buffers VL2 - Spread Bearing Design

OSG - Oil Sight Glass

H - Hollow Shaft Cover

VL3 - Oil Safe Spread Bearing Design OA - Oil Expansion Chamber

H66 - IP66 Hollow Shaft Cover VL4- Drywell Drop Bearing Design OC - Oil Cooler

SH - Shrink Disc & Cover

LX- Double Solid Shaft

WC - Water Cooling Cover

VSH - Heavy Duty Shrink Disc & Cover SM5 - Stainless Steel Output Shaft OT - Oil Reservoir Tank

M - GRIPMAXX

™

SWA - Special Hollow Shaft

MDP - Magnetic Drain Plug

PR - Flange Pilot Removal

SWV - Special Solid Shaft

ADP - Additional Drain Plug

Shaft Diameter (If required)

B5 Flange Diameter (If required)

SCP Drive Shaft Diameter (If required)

see pages 454 - 459

see page 35

Input

Shaft

NEMA

Adapter

IEC

Integral Motors

Integral Energy Efficent Motors

Scoop

Motor

Platform

Servo Adapter

(Keyed)

W

N56C

IEC 63

63S/4 - 0.16hp

160L/4 - 20hp

80LH/4 - 1hp

200LH/4 - 40hp

S56

MKN056

SEP 100

N140TC

IEC 71

63L/4 - 0.25hp

180MX/4 - 25hp

90SH/4 - 1.5hp

225SH/4 - 50hp

S140T

MKN140

SEP 130

N180TC

IEC 80

71S/4 - 0.33hp

180LX/4 - 30hp

90LH/4 - 2hp

225MH/4 - 60hp

S180T

MKN180

SEP 165

N210TC

IEC 90

71L/4 - 0.50hp

200L/4 - 40hp

100LH/4 - 3hp

250MH/4 - 75hp

S210T

MKN210

SEP 215

N250TC

IEC 100

80S/4 - 0.75hp

225S/4 - 50hp

112MH/4 - 5hp

280SH/4 - 100hp

S250T

MKN250

SEP 300

N280TC

IEC 112

80L/4 - 1hp

225M/4 - 60hp

132SH/4 - 7.5hp

280MH/4 - 125hp

S280T

MKN280

Servo Adapter

(Clamp)

N320TC

IEC 132

90S/4 - 1.5hp

250M/4 - 75hp

132MH/4 - 10hp

315SH/4 - 150hp

S320T

MKN320

N360TC

IEC 160

90L/4 - 2hp

280S/4 - 100hp

160MH/4 - 15hp

315MH/4 - 175hp

S360T

MKN360

SEK 100

N400TC

IEC 180

100L/4 - 3hp

280M/4 - 125hp

160LH/4 - 20hp

315MAH/4 - 200hp

S400T

MKN400

SEK 130

IEC 200

100LA/4 - 5hp

315S/4 - 150hp

180MH/4 - 25hp

315LH/4 - 250hp

SEK 165

IEC 225

112M/4 - 5.4hp

315M/4 - 175hp

180LH/4 - 30hp

SEK 215

IEC 250

132S/4 - 7.5hp

315MA/4 - 200hp

SEK 300

IEC 280

132M/4 - 10hp

315L/4 - 250hp

IEC 315

160M/4 - 15hp Other Speeds Available

Other Speeds Available

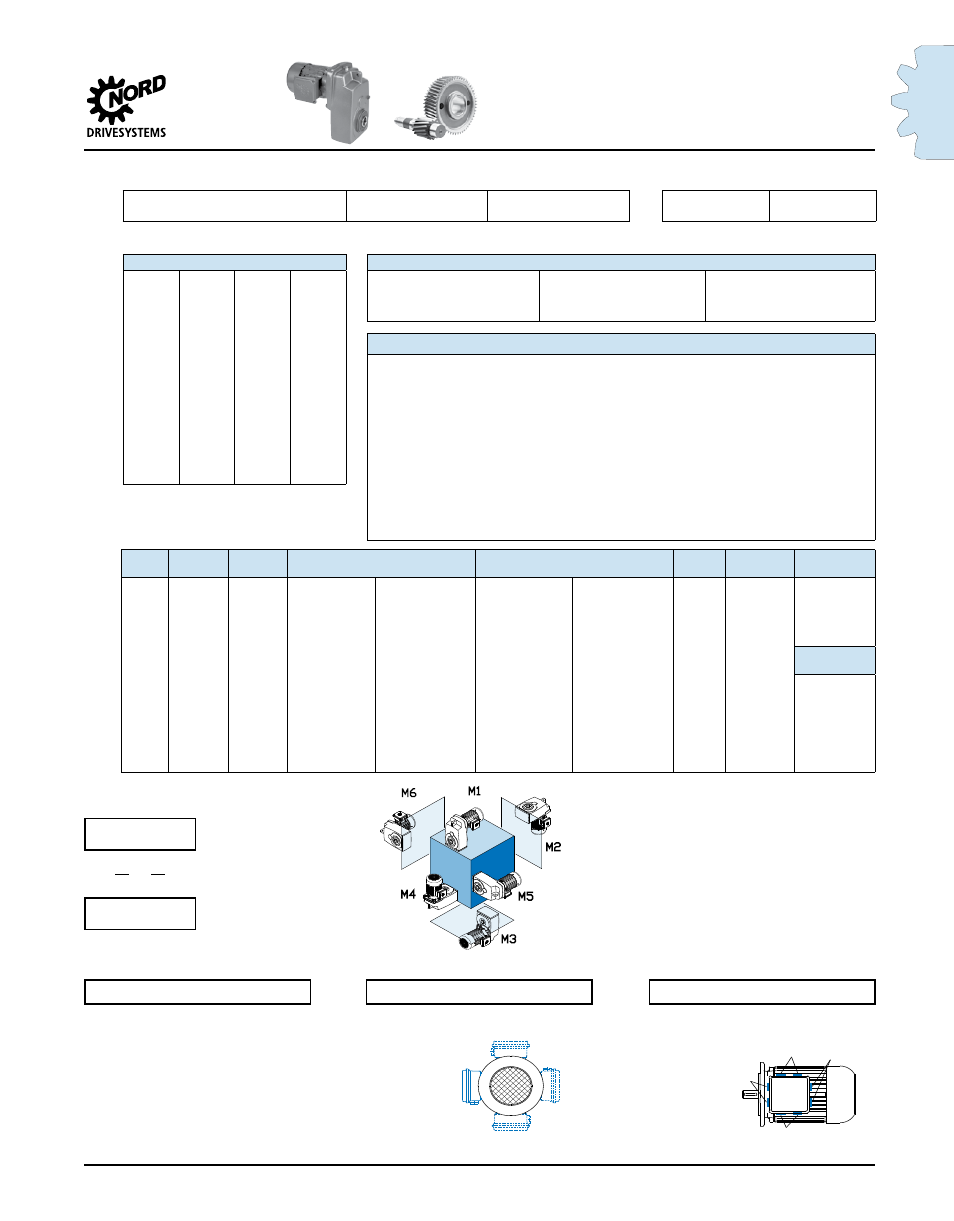

M1

M2

M6

M4

M3

M5

Product Specifications

Gearmotor Only Details

Voltage & Frequency

Terminal Box Pos.

Conduit Entry Loc.

230/460V-60Hz (460V only ≥ 40 hp)

TB1

CE I ∗

575V-60Hz

TB2

CE II

208V-60Hz

TB3

CE III ∗

400V-50Hz

TB4

CE IV

115/230V-60Hz, 1 ph.

Other ___________

∗ Brakemotor

TB2

TB1

TB4

TB3

CE III*

CE II

CE IV

CE I*

Mtg. Pos. M1 Shown

Mtg. Pos. M1 Shown

Ratio

Mounting Position

Paint

Lubricant

:1

M1

Standard Stainles Steel Paint

Standard

M2

NSD+ (gray)

Synthetic

see pages 270 - 314

M3

NSD+W (white)

Food Grade

OR

M4

NSD-X3 (gray)

Other _______

Output Speed

M5

NSD-X3W (white)

rpm

M6

Casting Primed

Special _______

Special _______

see pages 270 - 314