General information, Cautions, Brake torque selection – NORD Drivesystems B1000 User Manual

Page 732: General selection considerations

www.nord.com

G730

General

Information

BRAKES

G1000 – Subject to Change Without Notice

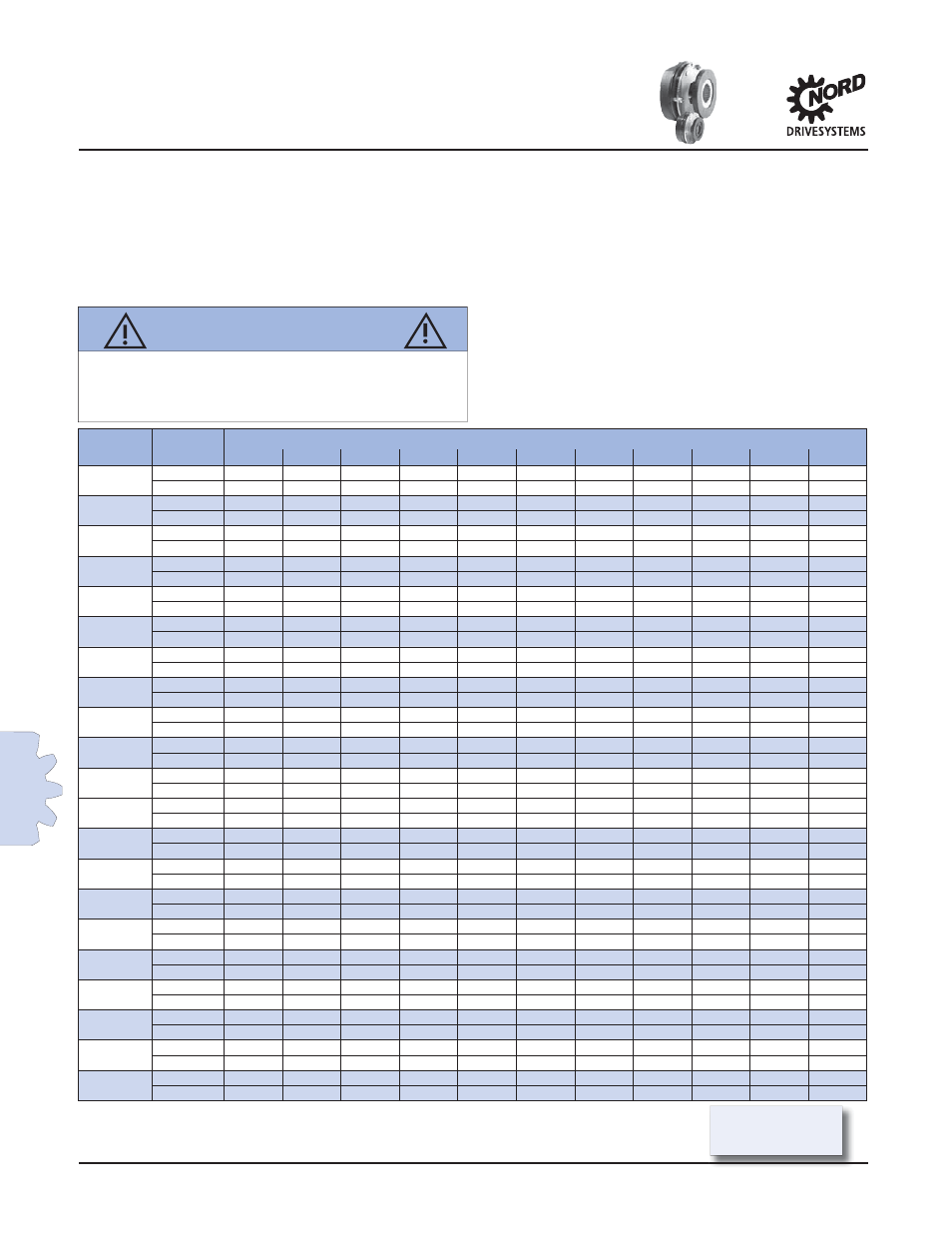

Brake Torque Selection

Each NORD motor size has a number of brake torque

sizes available. The bold value in the table below is

the standard brake torque size for each motor.

Example for ordering: SK 32 - 80S/4 BRE 10

(BRE 10 indicates the unit has a brake torque size of 10 Nm)

CAUTIONS

BRE800 and BRE1200 brakes may only be controlled with a

fast reaction rectifi er (overexcitation), the maximimum per-

missible nominal currents of the rectifi er must be considered!

Motor

Frame

Units

Brake Size

BRE5

BRE10

BRE20

BRE40

BRE60

BRE100

BRE150

BRE250

BRE400

BRE800

BRE1200

63S/L

Nm

5

10 *

1)

lb-ft

3.7

7.4 *

1)

71S/L

Nm

5

10 *

lb-ft

3.7

7.4

80S

Nm

5

10

20 *

lb-ft

3.7

7.4

15 *

80L

Nm

5

10

20 *

lb-ft

3.7

7.4

15 *

90S

Nm

10

20

40 *

lb-ft

7.4

15

30 *

90L

Nm

10

20

40 *

lb-ft

7.4

15

30

100L

Nm

20

40

60 *

1)

lb-ft

15

30

44

100LA/4

Nm

20

40

60 *

1)

lb-ft

15

30

44 *

1)

112M

Nm

20

40

60

lb-ft

15

30

44

132S

Nm

60

100

150

lb-ft

44

74

110

132M

Nm

60

100

150

lb-ft

44

74

110

132SM

Nm

60

100

150

lb-ft

44

74

110

160M

Nm

100

150

250

lb-ft

74

110

185

160L

Nm

100

150

250

lb-ft

74

110

185

180MX/LX

Nm

150

250

lb-ft

110

185

200L

Nm

250

400

lb-ft

185

295

225S

Nm

400

800 *

2)

lb-ft

295

590 *

2)

250M

Nm

800 *

2)

lb-ft

590 *

2)

280 S/M

Nm

800 *

2)

1200 *

3)

lb-ft

590 *

2)

885 *

3)

+ weight

kg

2

3

5.5

7

10

16

22

32

50

80

100

lb

4.4

6.6

12.1

15.4

22

35

49

71

110

176

220

+ inertia

kgm

2

x 10

-3

0.015

0.045

0.153

0.45

0.86

1.22

2.85

6.65

19.5

39

39

lb-ft

2

x 10

-3

0.356

1.07

3.63

10.7

20.4

29.0

67.7

158

463

926

926

* IP66 – IP66 brake not possible.

1) Brake release lever “HL” and “FHL” not possible.

2) When used as a stopping brake, evaluation of brake work is essential.

3) Designed as holding brake or emergency stop brake only.

1 Nm = 0.738 lb-ft

1 lb-ft = 1.36 Nm

General Selection Considerations

NORD relies on the equipment builder to specify ap-

propriate brake sizing for their application, while

giving consideration to the following:

• For most applications, we advise sizing the brake to

1.5 - 2 times the motor rated torque.

• For vertical applications, it may be advisable to size

the brake size up to 3 times the motor rated torque.

• For some applications, it may be necessary to specify

a reduced brake torque setting to prevent, excessive

peak load conditions developed at the reducer output.

• On travel drive applications, excessive brake torque

may lead to wheel skid, & excess hoist-cable swing.