Caution – NORD Drivesystems B1000 User Manual

Page 677

www.nord.com

Input

Section

INPUT SECTION

F675

G1000 – Subject to Change Without Notice

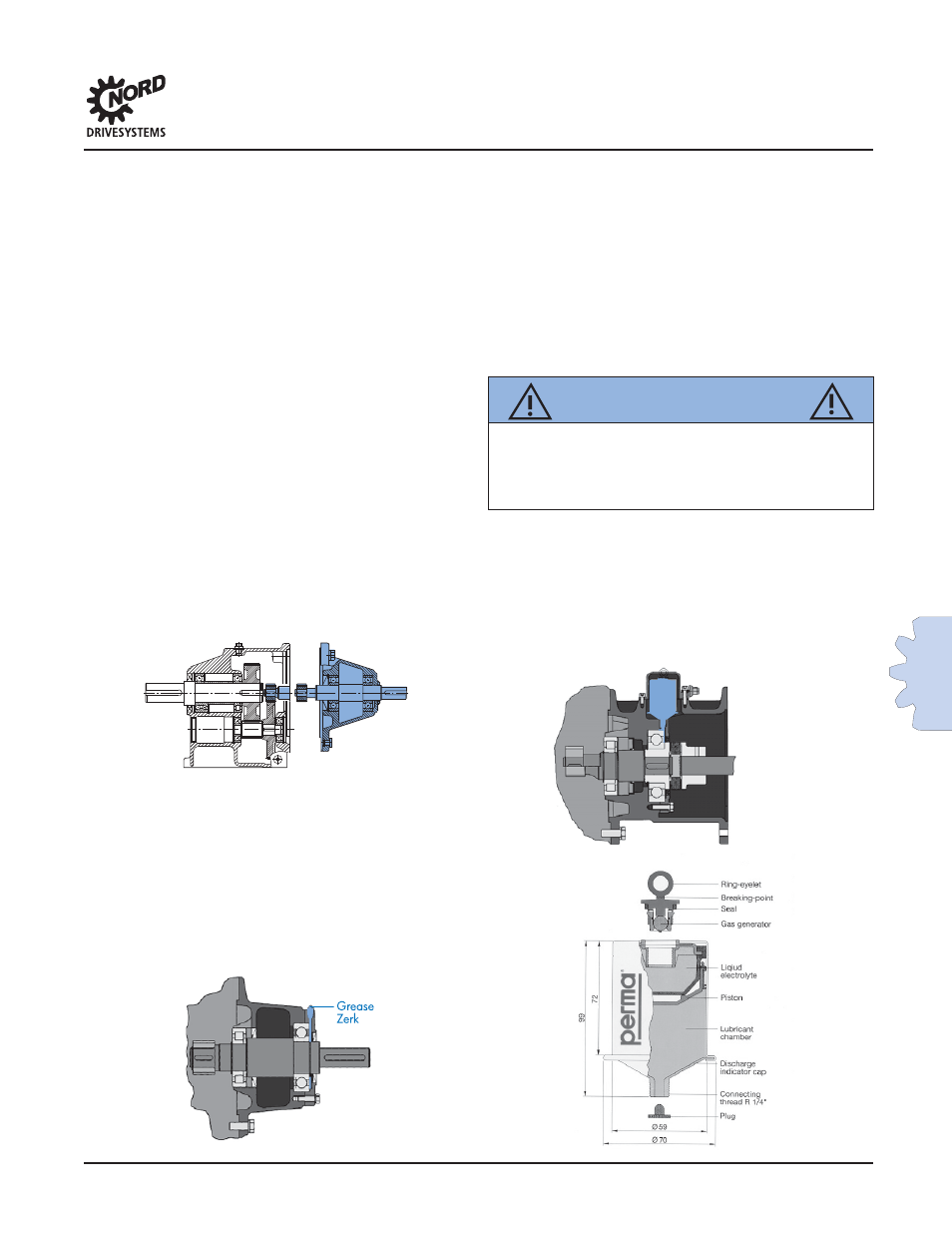

Integral Motors

NORD provides integral motors that mount directly

to the gearbox. Integral motor mounting eliminates

the need for costly v-belts or sheaves and directly cou-

ples the motor to the reducer. This also results in a

dimensionally compact one-piece package.

NORD high performance integral motors are avail-

able in many operational voltages, are inverter duty

rated, and offer many valuable options including

energy effi cient motors and power off brakes. For

more information on integral motors, see the cata-

logs motor section (section G).

Solid Input Shaft

Designed to mount couplings, sheaves or sprockets,

which transfer torque from the prime mover. The in-

put shaft is made from ANSI 1045 or stronger mate-

rial dimensioned with long keys according to ANSI

B17 standards. Bearings are sized to handle overhung

loads resulting from belt or sprocket inputs. See Sec-

tion A for more information on the capacity of each

input housing assembly. The maximum gearbox in-

put power rating is indicated in the speed reducer

performance tables.

The bearings of solid input shaft type W of the larger

gear units require re-lubrication at a regular interval.

This is necessary for double-stage gearboxes sizes

SK62 or SK6282 and larger, and triple-stage gear-

boxes from size SK73, SK7382 or SK9072.1 and larger.

To lubricate the bearing of the input shaft, approxi-

mately 1 oz (25 to 30g) of NIGI 2EP lithium-based

grease should be added by the grease zerk approxi-

mately every 4000 service hours. To insure adequate

service intervals, the grease zerk can be replaced with

an Automatic Lubricator.

Automatic Lubricator

Double-reduction gearboxes sizes SK62, SK6282 and

larger and triple reduction gearboxes SK73, SK6382,

SK9072.1 and larger with NEMA C-face or IEC adapt-

ers larger than 250TC/IEC160 are provided with an au-

tomatic lubricator. Automatic lubricators contain 120

cm3 (4 oz) of grease that is released over time to the

outboard adapter bearing. With 8 hours/day opera-

tion the lubricator will last 12 months. The automatic

lubricator is designed for ambient temperatures be-

tween 32ºF (0ºC) and 104ºF (40ºC).

CAUTION

The PERMA Automatic Lubrication canister is not

recommended for applications where the motor is

installed vertically. For alternate solutions, please

consult NORD with “the application details.”

The automatic lubricator must be activated before

the gearbox is put into operation. Activation is ac-

complished by turning the plastic eyelet in to the

canister until the eyelet breaks off. For replacement

automatic lubricators order by the part number:

28301000 - Standard canister

28301010 - Food grade canister