Engineering nord service factor – NORD Drivesystems B1000 User Manual

Page 65

www.nord.com

A63

G1000 – Subject to Change Without Notice

INTRODUCTION

EXAMPLE for Helical-worm gearmotor:

A coiler operates 16 hours/day with 300 cycles/hour

with a calculated m

af

= 2.5. Ambient temperature is

120ºF and the unit operates 18 minutes per hour.

From the chart, fi nd 300 cycles/hour and follow the

axis vertically up until you intersect curve B. From the

intersection point, move horizontally left to fi nd the

service factor f

B

= 1.5 based on 16 hours/day opera-

tion.

The service factor f

B

for helical-worms must be modi-

fi ed for the ambient temperature factor f

B1

and duty

cycle factor f

B2

.

The combined service factor

f

Bcombined

= f

B

x f

B1

x f

B2

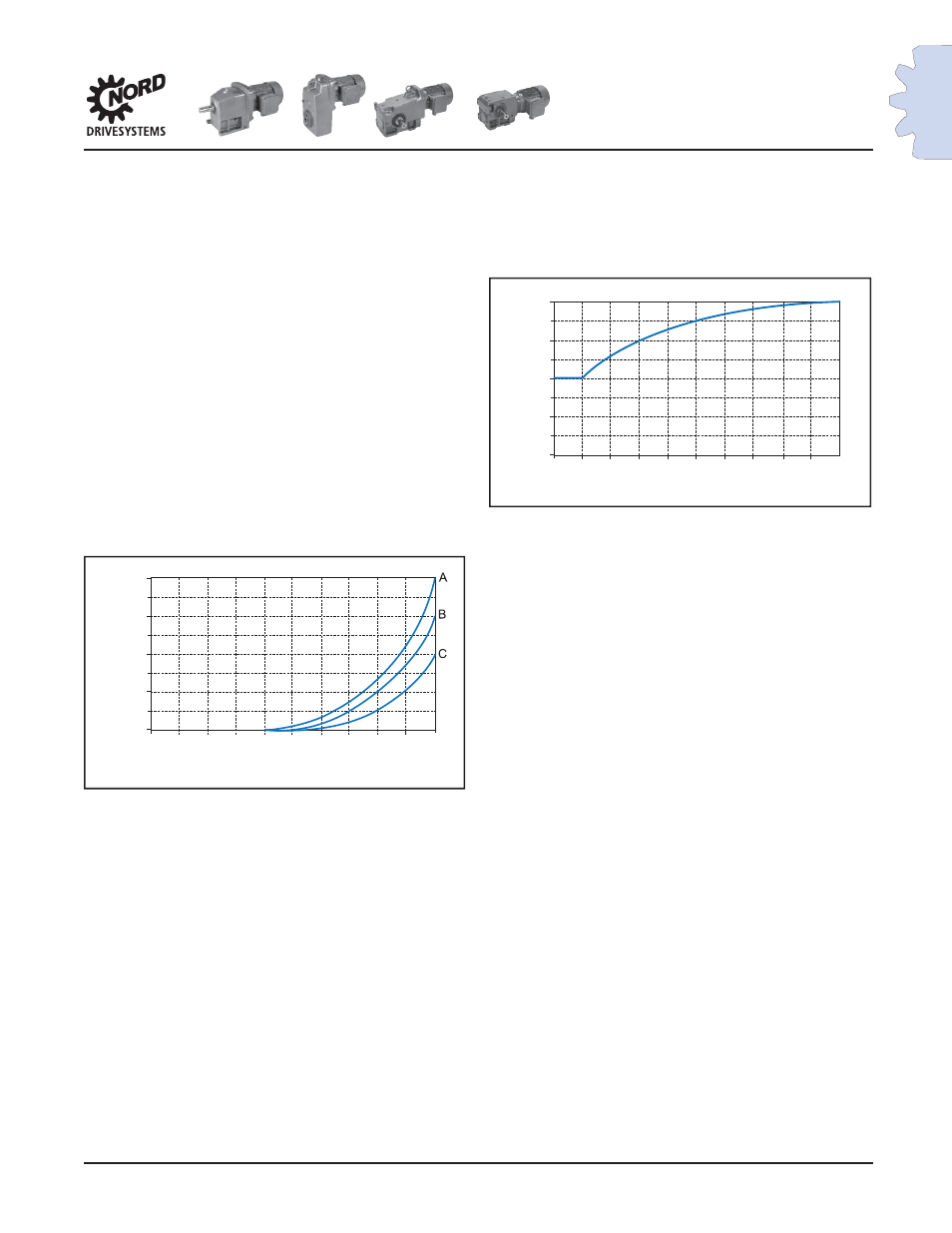

To fi nd the ambient temperature factor f

B1

use the

following chart based on ambient temperature.

To fi nd the duty cycle factor f

B2

use the following

chart based on how many minutes per hour the unit

is running.

In this example,

f

Bcombined

= (f

B

= 1.50) x (f

B1

=1.30) x (f

B2

= 0.90) = 1.76

When selecting worm gear reducers, multi-thread

(multi-start) worms must be used where shock load-

ing exists and where the driven machine may back-

drive the gearbox for short periods. Multi-thread

worms have z

1

(number of threads) greater than or

equal to 2.

m

af

≤ 0.25 all numbers of worm threads (z

1

) are possible

m

af

≤ 3.00 z

1

≥ 3 is recommend

m

af

≤ 10.00 z

1

≥ 6 is recommend

Refer to the worm reducer selection pages in this cat-

alog (pages and fi nd the any ratio with z

1

≥ 3. Then

refer to the gearmotor selection pages and choose a

gearmotor with a service factor of 1.76 or greater.

Engineering

NORD

Service Factor

Temper

atur

e F

a

c

tor f

B1

Ambient Temperature °F

1.4

1.3

1.2

1.1

1.0

50

68

86

104

122

32

1.0

0.9

0.8

0.7

0.6

0

12

24

36

48

60

Run Time Minutes/Hour

Dut

y C

y

cle F

a

c

tor f

B2