Lubrication, Lubrication types – NORD Drivesystems B1000 User Manual

Page 44

www.nord.com

INTRODUCTION

Lubrication

A42

G1000 – Subject to Change Without Notice

Lubrication Types

Proper gearbox lubrication is essential in order to reduce friction, heat, and component wear. Lubricants re-

duce heat and wear by inserting a protective “fl uid boundary” between mating parts and preventing direct

metal to metal contact. Lubricants also help prevent corrosion and oxidation, minimize foam, improve heat

transfer, optimize reducer effi ciency, absorb shock loads and reduce noise.

Mounting position not only determines the proper fi ll-level but may also have some effect on fi nal reducer

assembly. If considering any mounting positions that are not shown as catalog-standard options, it is critical

that the customer consult with NORD prior to ordering. Unless otherwise specifi ed, NORD supplies most all

gear units (*) factory-fi lled with the standard lubrication type and the appropriate amount of lubricating oil.

* Gear units SK10282, SK10382, SK11282, SK11382, SK12382, and SK9096.1 are supplied without oil.

Oil Formulation Codes

MIN-EP

Mineral Oil with EP Additive

PAO

Synthetic Polyalphaolefi n Oil

PG

Synthetic Polyglycol Oil

FG

Food-Grade Oil

FG-PAO

Food-Grade, Synthetic Polyalphaolefi n Oil

Important Notes

• In worm gears avoid using (EP) gear oils that contain

sulfur-phosphorous chemistries, as these additives can

react adversely with bronze worm gears and accelerate

wear.

• Food grade lubricants must be in compliance with FDA

212 CFR 178.3570 and qualify as a NSF-H1 lubricant.

Please consult with lubrication manufacture for more

information.

• When making a lubrication change, check with the

lubrication supplier to assure compatibility & to obtain

recommended cleaning or fl ushing procedures.

• Do not mix different oils with different additive packages

or different base oil formulation types. Polyglycol (PG)

oils are not miscible with other oil types and should

never be mixed with mineral oil, or Polyalphaolefi n

(PAO)

oil.

• Please Consult NORD if considering cold-temperature

oils below an ISO Viscosity VG100 or lower.

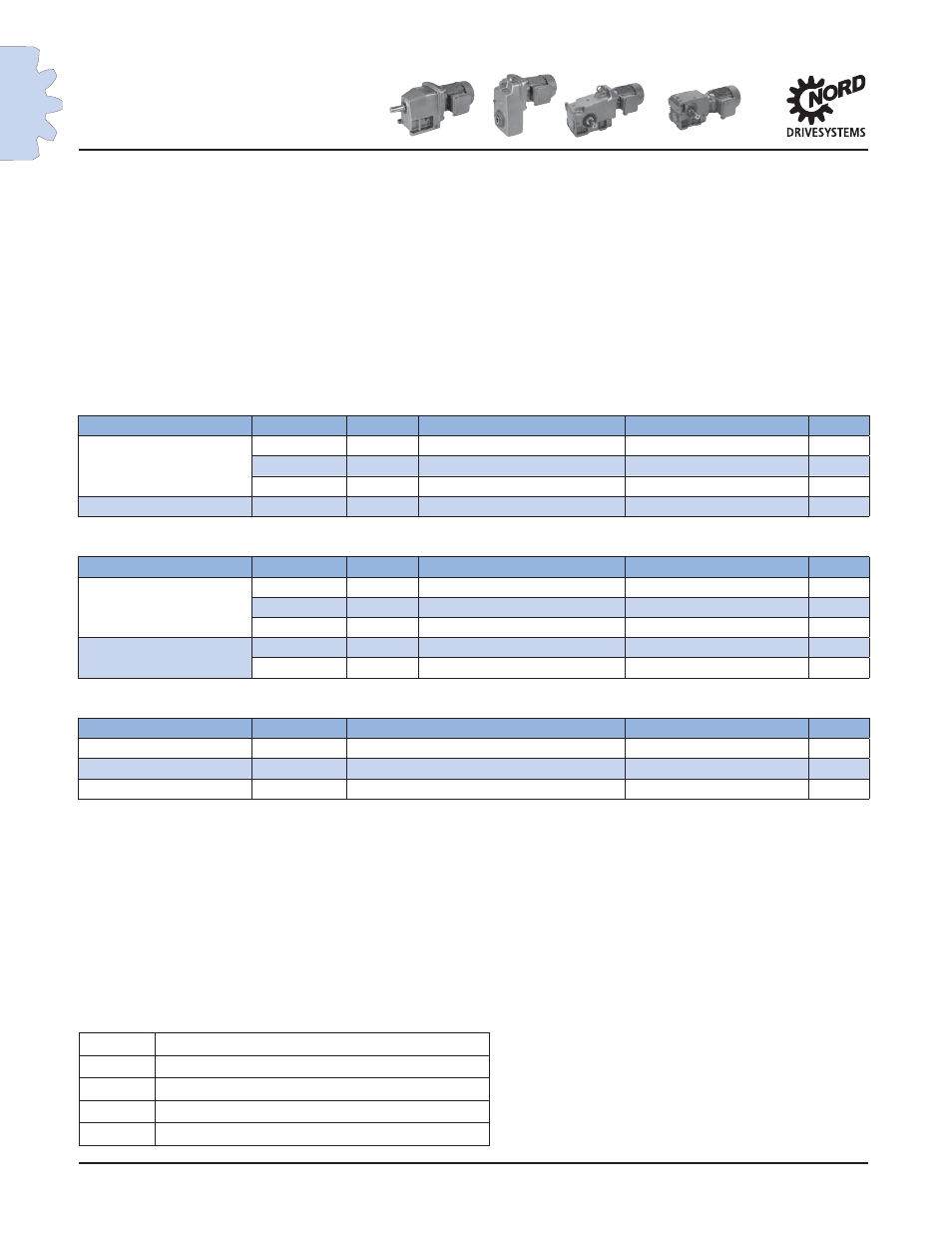

Standard Oil Lubricants

Gear Unit Type

ISO Viscosity

Oil Type

Ambient Temperature Range

Manufacturer Brand/Type

Notes

Helical In Line, Parallel-

Shaft & Bevel

VG220

MIN-EP

0 to 40ºC (32 to 104º)

Mobilgear 600XP220

VG220

PAO

-35 to 60ºC (-31 to 140ºF)

Mobil SHC630

VG220

FG

-5 to 40ºC (23 to 104ºF)

Fuchs FM220

Helical Worm

VG680

PAO

0 to 60ºC (32 to 140ºF)

Mobil SHC636

Optional Oil Lubricants

Gear Unit Type

ISO Viscosity

Oil Type

Ambient Temperature Range

Manufacturer Brand/Type

Notes

Helical In Line, Parallel-

Shaft & Bevel

VG460

PAO

-35 to 80ºC (-31 to 176ºF)

Mobil SHC 634

-

VG150

PAO

-35 to 25ºC (-31 to 77ºF)

Mobil SHC629

-

VG220

FG-PAO

-35 to 60ºC (-31 to 140ºF)

Mobil/Cibus SHC220

-

Helical Worm

VG460

PAO

0 to50ºC (32 to 122ºF)

Mobil SHC 634

-

VG460

FG-PAO

0 to50ºC (32 to 122ºF)

Mobil/Cibus SHC460

-

Standard Bearing Grease Lubricants

Grease Type/Thickener

NLGI Grade

Ambient Temperature Range

Manufacturer Brand/Type

Notes

Standard (Li-Complex)

NLGI 2

-30 to 60ºC (-22 to 140ºF)

Mobil Grease XHP222

High Temp (Polyurea)

NLGI 2

-25 to 80ºC (-13 to 176ºF)

Mobil Polyrex EP 2

Food-Grade (AL-Complex)

NLGI 2

-25 to 40ºC (-13 to 104ºF)

Mobil Grease FM222

Stocked Lubricants

Standard product on serviceable gear units

Standard product on maintenance free gear units