Engineering agma service classes, Application – NORD Drivesystems B1000 User Manual

Page 69

www.nord.com

A67

G1000 – Subject to Change Without Notice

INTRODUCTION

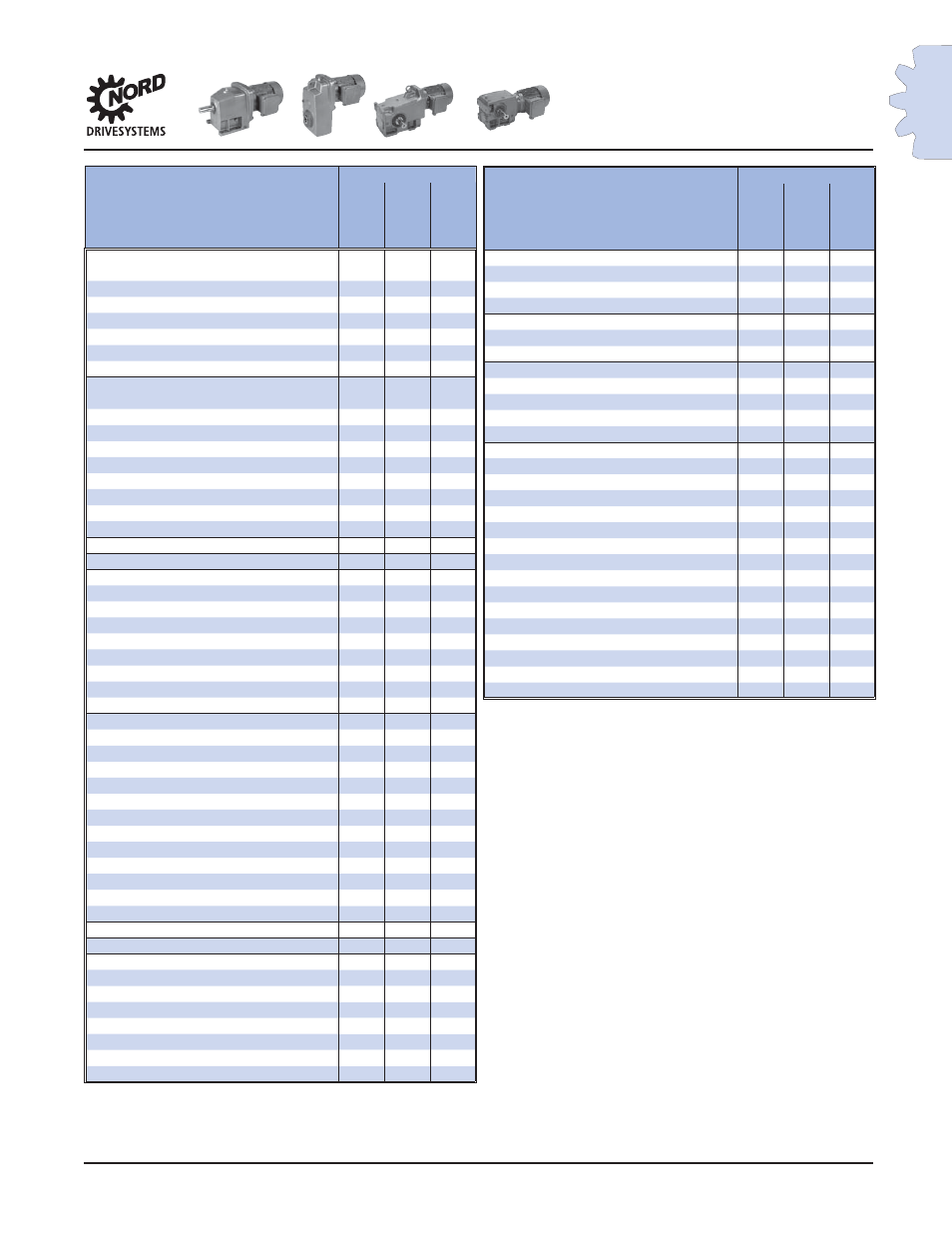

Application

Load Duration

Up to

3 hrs

per

day

3-10

hrs

per

day

Over

10 hrs

per

day

PLASTICS INDUSTRY –

PRIMARY PROCESSING

Intensive InternaI Mixers

Batch Mixers

III

III

III

Continuous Mixers

II

II

II

Batch Drop MiII – 2 smooth roIIs

II

II

II

Continuous Feed, HoIding &

II

II

II

Biend MiII CaIendars

II

II

II

PLASTICS INDUSTRY –

SECONDARY PROCESSING

BIow MoIders

II

II

II

Coating

II

II

II

FiIm

II

II

II

Pipe

II

II

II

Pre-PIasticizers

II

II

II

Rods

II

II

II

Sheet

II

II

II

Tubing

II

II

II

PULLERS – BARGE HAUL

II

II

II

PUMPS

CentrifugaI

I

I

II

Proportioning

II

II

II

Reciprocating

SingIe Acting, 3 or more cyIinders

II

II

II

DoubIe Acting, 2 or more cyIinders

II

II

II

Rotary

Gear Type

I

I

II

Lobe

I

I

II

Vane

I

I

II

RUBBER INDUSTRY

Intensive InternaI Mixers

Batch Mixers

III

III

III

Continuous Mixers

II

II

II

Mixing MiII

2 smooth roIIs

II

II

II

1 or 2 corrugated roIIs

III

III

III

Batch Drop MiII – 2 smooth roIIs

II

II

II

Cracker Warmer – 2 roII, 1 corrugated roII

III

III

III

Cracker – 2 corrugated roIIs

III

III

III

HoIding, Feed & BIend MiII – 2 roIIs

II

II

II

Refi ner – 2 roIIs

II

II

II

CaIendars

II

II

II

SAND MULLER

II

II

II

SEWAGE DISPOSAL EQUIPMENT

Bar Screens

II

II

II

ChemicaI Feeders

II

II

II

Dewatering Screens

II

II

II

Scum Breakers

II

II

II

SIow or Rapid Mixers

II

II

II

SIudge CoIIectors

II

II

II

Thickener

II

II

II

Vacuum FiIters

II

II

II

Application

Load Duration

Up to

3 hrs

per

day

3-10

hrs

per

day

Over

10 hrs

per

day

SCREENS

Air Washing

I

I

II

Rotary – Stone or GraveI

II

II

II

TraveIing Water Intake I

I

I

I

SCREW CONVEYORS

UniformIy Ioaded or Fed

I

I

II

Heavy Duty

I

II

II

SUGAR INDUSTRY

Beet SIicer

III

III

III

Cane Knives

II

II

II

Crushers

II

II

II

MiIIs (Iow speed end)

III

III

III

TEXTILE INDUSTRY

Batchers

II

II

II

CaIendars

II

II

II

Cards

II

II

II

Dry Cans

II

II

II

Dyeing Machinery

II

II

II

Looms

II

II

II

MangIes

II

II

II

Nappers

II

II

II

Pads

II

II

II

Siashers

II

II

II

Soapers

II

II

II

Spinners

II

II

II

Tenter Frames

II

II

II

Washers

II

II

II

Winders

II

II

II

Notes to GEARMOTOR SERVICE FACTOR tabIe:

1) The cIass numbers Iisted for paper miII appIications are

consistent with those shown in TAPPI (TechnicaI Association

of PuIp and Paper Industry) TechnicaI Information Sheet 0406-

18 1967, Service Factors for Gears on major Equipment in the

Paper and PuIp Industry.

2) Anti-friction bearings onIy.

3) A CIass Number of I may be applied at base speed of a super-

caIendar operating over a speed range of part-range constant

horsepower and part-range constant torque where the con-

stant horsepower speed range is greater than 1.5 to 1. A CIass

Number of II is appIicabIe to supercaIendars operating over

the entire speed range at constant torque or where the con-

stant horsepower speed range is Iess than 1.5 to1.

Engineering

AGMA

Service Classes