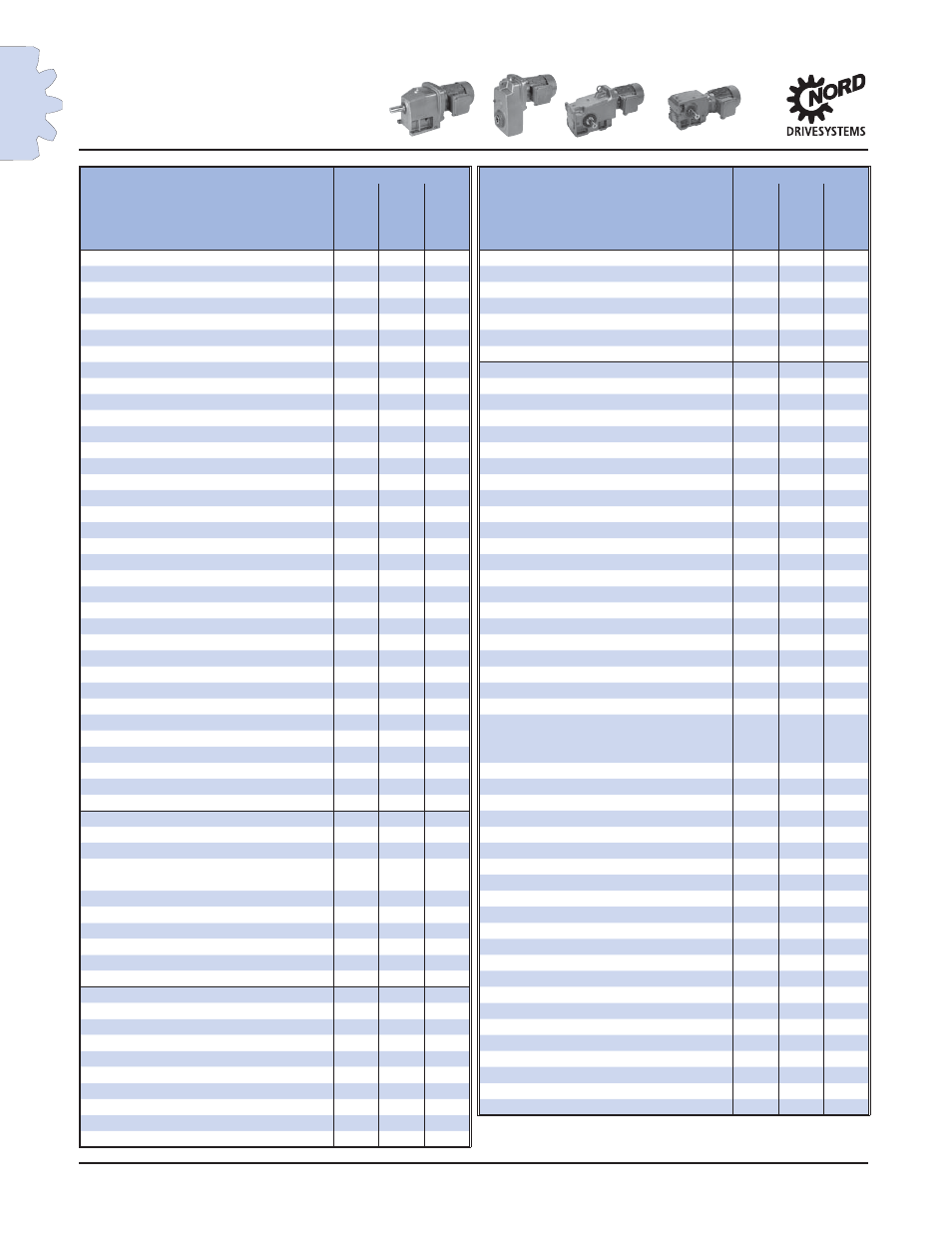

Engineering agma service classes, Application – NORD Drivesystems B1000 User Manual

Page 68

www.nord.com

A66

INTRODUCTION

G1000 – Subject to Change Without Notice

Application

Load Duration

Up to

3 hrs

per

day

3-10

hrs

per

day

Over

10 hrs

per

day

LUMBER INDUSTRY

Barkers

SpindIe Feed

II

II

II

Main Drive

III

III

III

Conveyors

Burner

II

II

II

Main or Heavy Duty

II

II

II

Main Iog

III

III

III

Re-saw, Merry-Go-Round

II

II

II

SIab

III

III

III

Transfer

II

II

II

Chains

FIoor

II

II

II

Green

II

II

III

Cut-Off Saws

Chain

II

II

III

Drag

II

II

III

Debarking Drums

III

III

III

Feeds

Edger

II

II

II

Gang

II

III

III

Trimmer

II

II

II

Long Deck

III

III

III

Log HauIs – IncIine – WeII Type

III

III

III

Log Turning Devices

III

III

III

Planer Feed

II

II

II

PIaner TiIting Hoists

II

II

II

RoIIs – Iive-off brg. – RoII Cases

III

III

III

Sorting TabIe

II

II

II

TippIe Hoist

II

II

II

Transfers

Chain

II

II

III

Craneway

II

II

III

Tray Drives

II

II

II

Veneer Lathe Drives

II

II

II

METAL MILLS

Draw Bench Carriage and Main Drive

II

II

II

Runout TabIe

Non-reversing

Group Drives

II

II

II

IndividuaI Drives

III

III

III

Reversing

III

III

III

SIab Pushers

II

II

II

Shears

III

III

III

Wire drawing

II

II

II

Wire Winding Machine

II

II

II

METAL STRIP PROCESSING MACHINERY

BridIes

II

II

II

CoiIers & UncoiIers

I

I

II

Edge Trimmers

I

II

II

FIatteners

II

II

II

Loopers (AccumuIators)

I

I

I

Pinch RoIIs

II

II

I

Scrap Choppers

II

II

II

Shears

III

III

III

Slitters

I

II

II

Application

Load Duration

Up to

3 hrs

per

day

3-10

hrs

per

day

Over

10 hrs

per

day

MILLS, ROTARY TYPE

BaII & Rod

Spur Ring Gear

III

III

III

HeIicaI Ring Gear

II

II

II

Direct Connected

III

III

III

Cement KiIns

II

II

II

Dryers & CooIers

II

II

II

PAPER MILLS

1)

Agitator (Mixer)

II

II

II

Agitator for Pure Iiquors

II

II

II

Barking Drums

III

III

III

Barkers – MechanicaI

III

III

III

Beater

II

II

II

Breaker Stack

II

II

II

CaIender

2)

II

II

II

Chipper

III

III

III

Chip Feeder

II

II

II

Coating RoIIs

II

II

II

Conveyors

Chip, Bark, ChemicaI

II

II

II

Iog (incIuding SIab)

III

III

III

Couch RoIIs

II

II

II

Cutter

III

III

III

CyIinder MoIds

II

II

II

Dryers

2)

Paper Machine

II

II

II

Conveyor Type

II

II

II

Embosser

II

II

II

Extruder

II

II

II

Fourdrinier RoIIs (IncIudes Iump,

Dandy RoII, Wire Turning, and

Return RoIIs)

II

II

II

Jordan

II

II

II

KiIn Drive

II

II

II

Mt. Hope RoII

II

II

II

Paper RoIIs

II

II

II

Platter

II

II

II

Presses – FeIt & Suction

II

II

II

PuIper

III

III

III

Pumps – Vacuum

II

II

II

ReeI (Surface Type)

II

II

II

Screens

Chip

II

II

II

Rotary

II

II

II

Vibrating

III

III

III

Size Press

II

II

II

SupercaIendar

3)

II

II

II

Thickener (AC Motor)

II

II

II

Thickener (DC Motor)

II

II

II

Washer (AC Motor)

II

II

II

Washer (DC Motor)

II

II

II

Wind and Unwind Stand

I

I

I

Winders (Surface Type)

II

II

II

Yankee Dryers

2)

II

II

II

Engineering

AGMA

Service Classes