Reducer tolerances – NORD Drivesystems B1000 User Manual

Page 62

www.nord.com

INTRODUCTION

A60

G1000 – Subject to Change Without Notice

Reducer

Tolerances

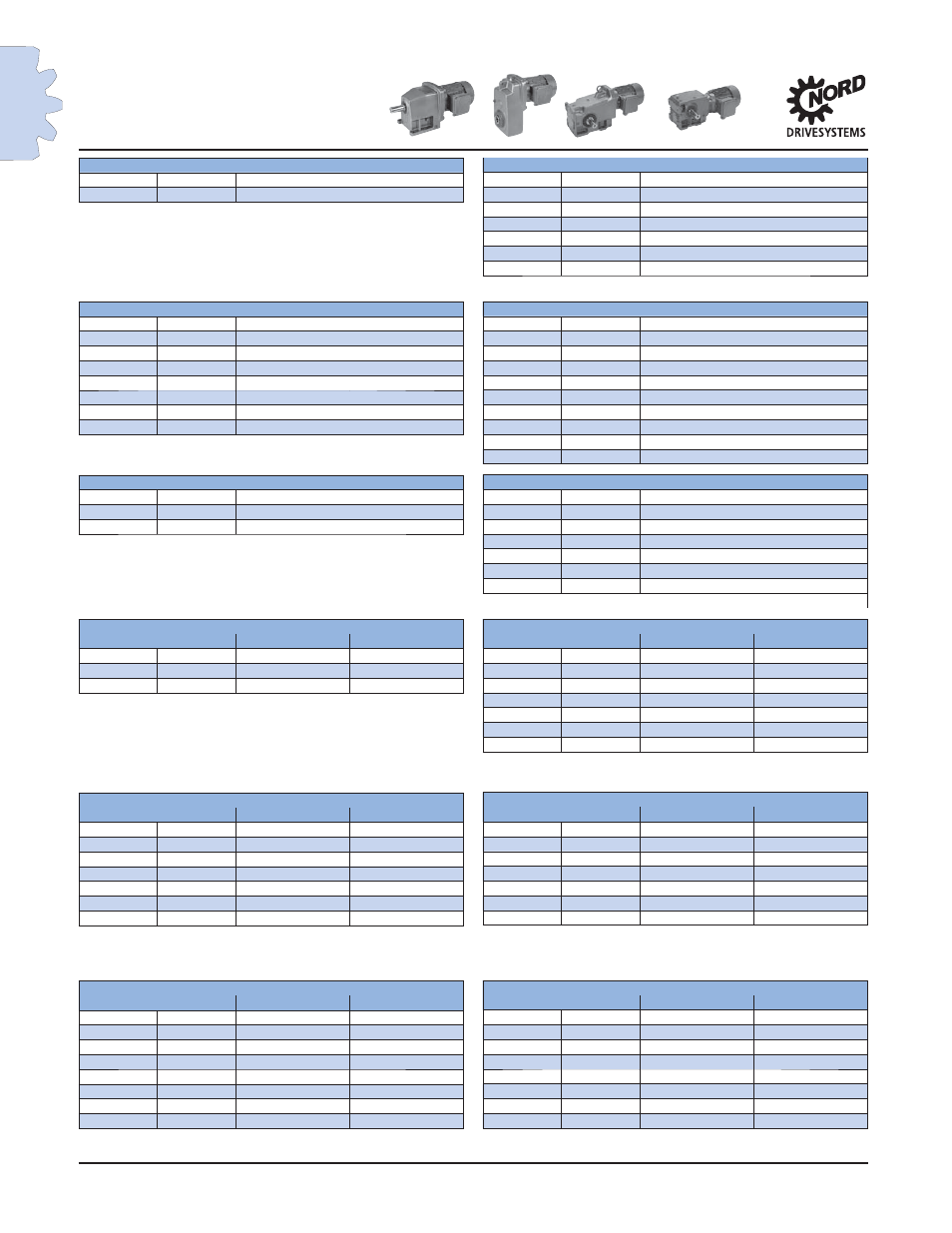

Solid Shaft Diameter Tolerance [in]

> 0.375

≤ 1.750

+0.0000 / -0.0005

> 1.750

≤ 7.500

+0.0000 / -0.0010

All Keys and Keyways: Inch - ANSI B17

Solid Shaft Drill & Tap Shaft End - Threaded Holes [in]

> ш 0.375

≤ ш 0.500

10-24 x 0.43

> ш 0.500

≤ ш 0.875

1/4-20 x 0.59

> ш 0.875

≤ ш 0.938

5/16-18 x 0.71

> ш 0.938

≤ ш 1.100

3/8-16 x 0.87

> ш 1.100

≤ ш 1.300

1/2-13 x 1.10

> ш 1.300

≤ ш 1.875

5/8-11 x 1.42

> ш 1.875

≤ ш 3.500

3/4-10 x 1.73

> ш 3.500

≤ ш 7.500

1-8 x 2.20

Keyed Hollow Bore Tolerances [in]

> ш 0.4375

≤ ш 1.6250

+0.0010 / -0.0000

> ш 1.6250

≤ ш 3.2500

+0.0012 / -0.0000

> ш 3.2500

≤ ш 7.0000

+0.0014 / -0.0000

Suggested Solid Shaft Tolerances for Keyed Hollow Bore [in]

Uniform Load

Shock Load

> ш 0.4375

≤ ш 0.8750

+0.0000 / -0.0005

+0.0000 / +0.0005

> ш 0.8750

≤ ш 4.5000

+0.0000 / -0.0010

+0.0000 / +0.0010

> ш 4.5000

≤ ш 7.0000

+0.0000 / -0.0012

+0.0000 / +0.0015

Customer Shaft Diameter Tolerance w/ Shrink Disk [in]

Shaft Diameter

Shaft Tolerance

Bore Tolerance

≥ ш 0.4375

≤ ш 0.6875

+0.0000 / -0.0004

+0.0007 / -0.0000

≥ ш 0.7500

≤ ш 1.1250

+0.0000 / -0.0005

+0.0008 / -0.0000

≥ ш 1.1250

≤ ш 1.9375

+0.0000 / -0.0006

+0.0009 / -0.0000

≥ ш 2.0000

≤ ш 3.1250

+0.0000 / -0.0007

+0.0011 / -0.0000

≥ ш 3.1875

≤ ш 4.6875

+0.0000 / -0.0008

+0.0013 / -0.0000

≥ ш 4.7500

≤ ш 7.0625

+0.0000 / -0.0009

+0.0015 / -0.0000

≥ ш 7.1250

≤ ш 7.5000

+0.0000 / -0.0011

+0.0018 / -0.0000

Inch Shaft Tolerances per ISO286-2, Class h6

Inch hollow bore tolerances per ISO286-2, Class H7

• Solid Shaft fi nish to be 125 micro inches (3.2mm) or smoother

Flange Pilot (AK or AK1) Tolerance [in]

Flange Pilot Diameter

Pilot Tolerance

Fit Class

> ш 1.969

≤ ш 3.150

+0.0005 / -0.0003

j6

> ш 3.150

≤ ш 4.724

+0.0005 / -0.0004

j6

> ш 4.724

≤ ш 7.087

+0.0006 / -0.0004

j6

> ш 7.087

≤ ш 9.055

+0.0000 / -0.0005

h6

> ш 9.055

≤ ш 9.843

+0.0000 / -0.0011

h6

> ш 9.843

≤ ш 12.402

+0.0000 / -0.0013

h6

> ш 12.402

≤ ш 15.748

+0.0000 / -0.0014

h6

> ш 15.748

≤ ш 19.685

+0.0000 / -0.0016

h6

Inch Pilot Tolerances per ISO286-2

Solid Shaft Diameter Tolerance

[mm]

> 10

≤ 18

+0.012 / +0.001

> 18

≤ 30

+0.015 / +0.002

> 30

≤ 50

+0.018 / +0.002

> 50

≤ 80

+0.030 / +0.011

> 80

≤ 120

+0.035 / +0.013

> 120

≤ 180

+0.040 / +0.015

> 180

≤ 190

+0.046 / +0.017

All Keys and Keyways: Metric - DIN 6885, class m6

Solid Shaft Drill & Tap Shaft End - Threaded Holes [mm]

> ш 10

≤ ш 13

M4 x 10

> ш 13

≤ ш 16

M5 x 12.5

> ш 16

≤ ш 21

M6 x 16

> ш 21

≤ ш 24

M8 x 19

> ш 24

≤ ш 30

M10 x 22

> ш 30

≤ ш 38

M12 x 28

> ш 38

≤ ш 50

M16 x 36

> ш 50

≤ ш 85

M20 x 42

> ш 85

≤ ш 130

M24 x 50

> ш 130

≤ ш 190

M30 x 60

Keyed Hollow Bore Tolerances [mm]

> ш 10

≤ ш 18

+0.018 / -0.000

> ш 18

≤ ш 30

+0.021 / -0.000

> ш 30

≤ ш 50

+0.025 / -0.000

> ш 50

≤ ш 80

+0.030 / -0.000

> ш 80

≤ ш 120

+0.035 / -0.000

> ш 120

≤ ш 180

+0.040 / -0.000

> ш 180

≤ ш 190

+0.035 / -0.000

Metric hollow bore tolerances per ISO286-2, Class H7

Suggested Solid Shaft Tolerances for Keyed Hollow Bore [mm]

Uniform Load

Shock Load

> ш 10

≤ ш 18

+0.000 / -0.011

+0.012 / +0.001

> ш 18

≤ ш 30

+0.000 / -0.013

+0.015 / +0.002

> ш 30

≤ ш 50

+0.000 / -0.016

+0.018 / +0.002

> ш 50

≤ ш 80

+0.000 / -0.019

+0.021 / +0.002

> ш 80

≤ ш 120

+0.000 / -0.022

+0.025 / +0.003

> ш 120

≤ ш 180

+0.000 / -0.025

+0.028 / +0.003

> ш 180

≤ ш 190

+0.000 / -0.029

+0.033 / +0.004

Uniform load: Mating shaft diameter tolerance per ISO286-2, class h6

Shock load: Mating shaft diameter tolerance per ISO286-2, class k6

Customer Shaft Diameter Tolerance w/ Shrink Disk [mm]

Shaft Diameter

Shaft Tolerance

Bore Tolerance

> ш 10

≤ ш 18

+0.000 / -0.011

+0.018 / -0.000

> ш 18

≤ ш 30

+0.000 / -0.013

+0.021 / -0.000

> ш 30

≤ ш 50

+0.000 / -0.016

+0.025 / -0.000

> ш 50

≤ ш 80

+0.000 / -0.019

+0.030 / -0.000

> ш 80

≤ ш 120

+0.000 / -0.022

+0.035 / -0.000

> ш 120

≤ ш 180

+0.000 / -0.025

+0.040 / -0.000

> ш 180

≤ ш 190

+0.000 / -0.029

+0.046 / -0.000

Metric Shaft Tolerances per ISO286-2, Class h6

Metric hollow bore tolerances per ISO286-2, Class H7

• Solid Shaft fi nish to be 125 micro inches (3.2mm) or smoother

Flange Pilot (AK or AK1) Tolerance [mm]

Flange Pilot Diameter

Pilot Tolerance

Fit Class

> ш 50

≤ ш 80

+0.012 / -0.007

j6

> ш 80

≤ ш 120

+0.013 / -0.009

j6

> ш 120

≤ ш 180

+0.014 / -0.011

j6

> ш 180

≤ ш 230

+0.000 / -0.013

h6

> ш 230

≤ ш 250

+0.000 / -0.029

h6

> ш 250

≤ ш 315

+0.000 / -0.032

h6

> ш 315

≤ ш 400

+0.000 / -0.036

h6

> ш 400

≤ ш 500

+0.000 / -0.040

h6

Metric Pilot Tolerances per ISO286-2

Casting Surfaces may differ slightly (approximately 0.125 inches or 3.2mm) from the specifi ed nominal dimensions as a result of the manufacturing process