Selection information – NORD Drivesystems B1000 User Manual

Page 14

www.nord.com

INTRODUCTION

A12

G1000 – Subject to Change Without Notice

Selection

Information

NORD Mass Acceleration Service Factoring

NORD often uses a calculation based system to prop-

erly assign a service factor. This system considers hours

of operation per day, the severity of the application

and the number of times the equipment is cycled. See

page 72 for additional detail.

4. Gearbox Type & Input

NORD gear drives are available in a number of

mechanical confi gurations including:

• Helical

in-line

• Clincher™ shaft mount

• Right-angle

helical-bevel

• Right-angle

helical-worm

NORD’s modular design allows for a number of differ-

ent inputs to be added to NORD reducers including:

• Integral

motor

• NEMA-C and IEC motor adapter

• Solid input shaft

• Servo motor adapter

• Sugar scoop mount

• Top motor mount platform

• NORDISC

TM

variable speed friction drives

• Titan

TM

variable speed belt boxes

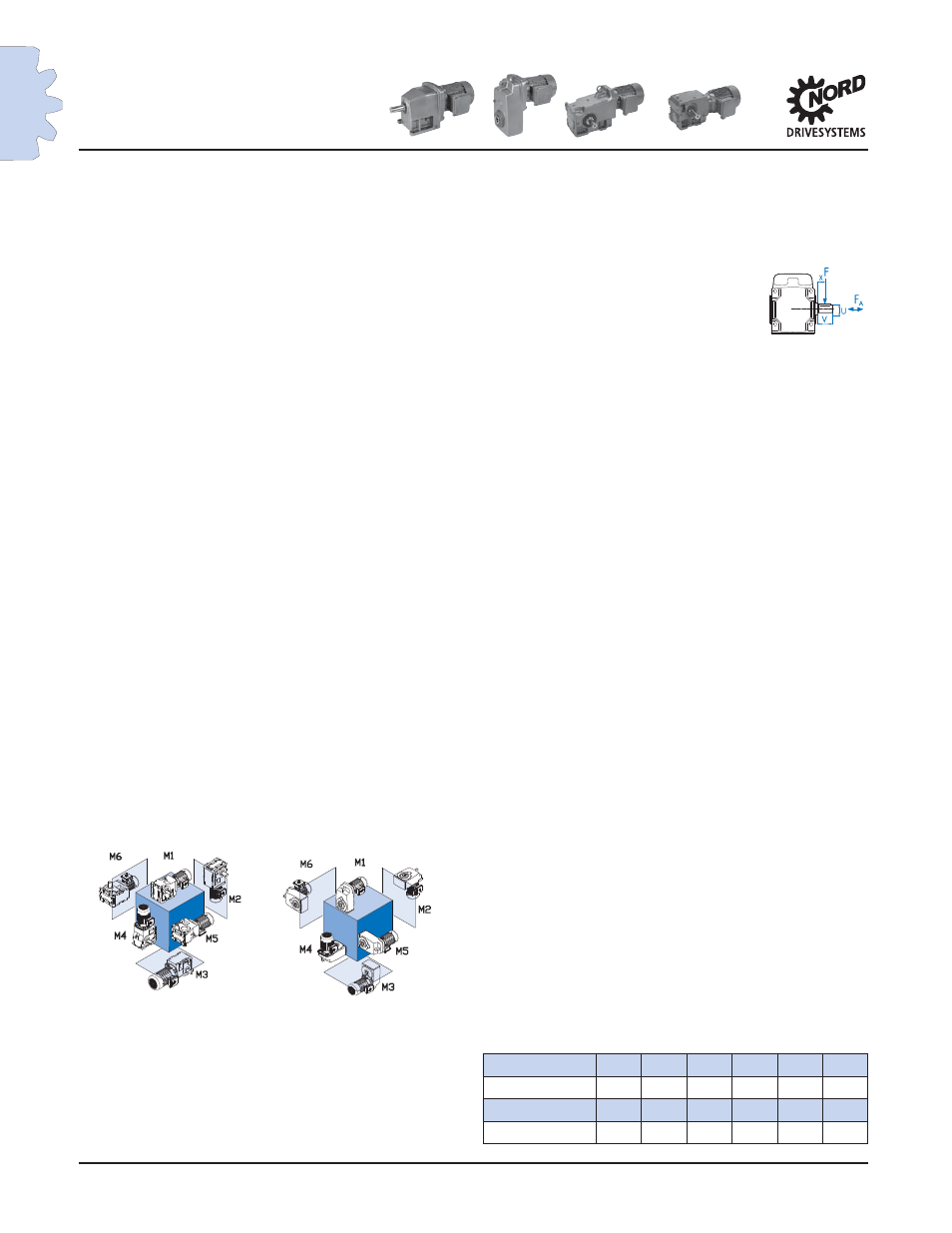

5. Mounting Position

The gearbox mounting position is an important and

often overlooked specifi cation. The mounting posi-

tion determines how much oil the gear reducer re-

quires, in addition to determining the position of the

oil drain, oil fi ll and vent on the gear drive. NORD

offers six basic mounting positions. If your applica-

tion requires a variation from the six basic mounting

positions, please contact NORD.

Many gearbox and motor options require a location

designation. For example a right-angle helical-bev-

el unit with a single solid shaft extension requires a

shaft extension side location. Please see page 23 for

additional options that require location designation.

6. Options

NORD offers a number of mechanical, protective,

paint & lubrication options for gear reducers & mo-

tors. Please see page 25 for gear unit options & refer

to the motor section (Section G) for motor options.

7. Checks

Overhung Load

An overhung or radial load exists when a force is

applied at right-angles to a shaft beyond the shaft’s

outermost bearing. Pulleys, sheaves and sprockets

will cause an overhung load when used as a power

take-off. The amount of overhung load will vary,

depending on the type of power take-off used and

where it is located on the shaft.

Overhung load [FQ] can be found in the gearmotor

rating tables and input shaft overhung load ratings

[FQ1] can be found on pages 58 - 69. Overhung load

capacities should not exceed the values in the table

to ensure long bearing life. Overhung load capacities

are to be applied at the midpoint of the shaft exten-

sion and without thrust loads.

To calculate overhung load see page 58.

Thrust Loads (Axial)

Loads that are directed towards or away from the

gearbox along the axis of the shaft are called thrust

or axial loads. Output shaft thrust capacity [FA] can

be found in the gearmotor rating tables. Input shaft

capacity [FA1] can be found on pages 68. Thrust load

capacities should not exceed the values listed in the

tables to ensure long bearing life. Thrust load capaci-

ties are listed for pure axial loads with no overhung

load. Contact NORD for combination loads or a more

exact examination of the application.

NEMA C-face Motor Weight Limits

When mounting a motor to a NORD NEMA C-face

motor adapter it is important to consider the motor’s

weight. Following is a table that includes the maxi-

mum motor weight the NEMA adapter can support.

If the motor exceeds the listed weight it must be ex-

ternally supported. When a C-face mounted motor

is externally supported care must be taken to ensure

that the support system does not impose additional

pre-loads on the NEMA motor adapter.

NEMA Weights

Motor FRAME

56C

143TC 145TC 182TC 184TC 210TC

Max Weight [lb]

66

88

110

130

175

220

Motor FRAME

250TC 280TC 324TC 326TC 365TC

Max Weight [lb]

440

550

770

1100

1540

M1

M2

M6

M4

M3

M5

R