Brake calculations, J × n t, J × n – NORD Drivesystems B1000 User Manual

Page 744

www.nord.com

G742

G1000 – Subject to Change Without Notice

BRAKES

Brake Size Calculation

Torque and inertias below are based on the motor

speed. Load side torques must always be divided by

the gear reduction ratio. Inertias must be divided by

the

square of the gear ratio. You must also consider

any external reduction ratio outside the gearbox.

Selection for holding loads

(static)

T

req

= T

stat

= T

load

× K

Selection for stopping loads

(static + dynamic)

Ȉ

J

= J

motor

+

J

load

Typically other inertias, like the gearbox, can be ignored.

T

dyn

=

Ȉ

J × n

T

req

= (T

dyn

+

T

load

)

× K

For driving loads use: –T

load

For overhauling loads use: +T

load

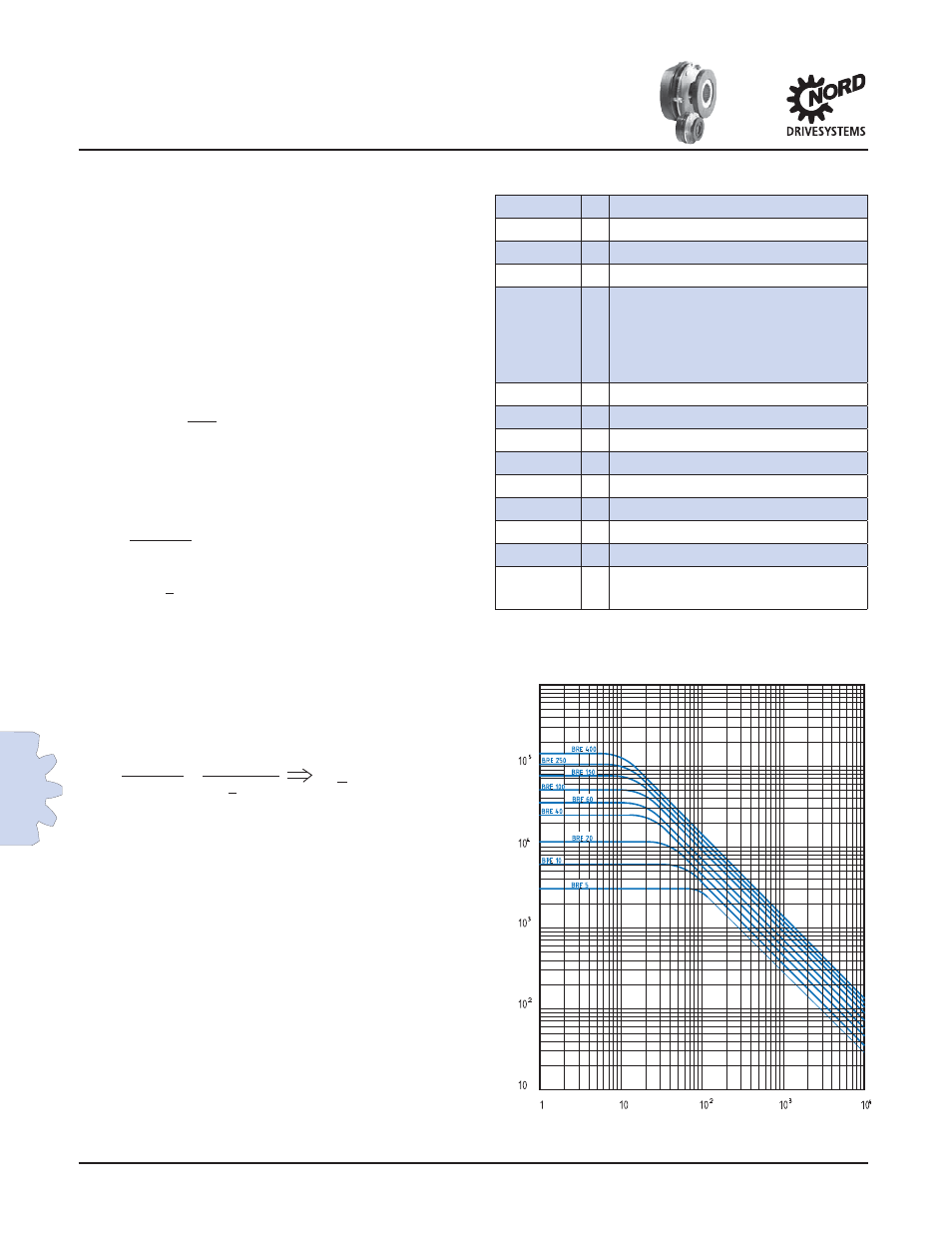

Brake Work Verifi cation

W =

Ȉ

J × n

2

×

T

B

W

<

W

max

For driving loads use: +T

load

For overhauling loads use: –T

load

The permissible values for W

max

(Friction work)

depend on the stopping frequency. See diagram at

right.

In applications where the brake is operated fre-

quently, two brake work values should be evaluated

to ensure adequate brake life: the braking work

compared to the braking frequency and the maximum

work limit for a single operation, such as an E-stop.

Reviewing these two values will help determine the

optimal solution and ensure long brake life.

Abbreviation Key

i

2

25.7

×

t

r

5880

T

B

+

T

load

c/h

=

Number of brakes per hour

J [lb-ft

2

]

=

Inertia

J

motor

[lb-ft

2

] =

Motor inertia

i

=

System reduction ratio

K

=

Safety factors. Based on ap-

plication and according to

industry rules and practices

Hoisting >2

Hoisting with people >2..3

Travel drives 0.5 to 1.5

T

B

[lb-in]

=

Brake torque

T

dyn

[lb-in]

=

Dynamic torque

T

req

[lb-in]

=

Required brake torque

T

load

[lb-in]

=

Load torque

T

stat

[lb-in]

=

Static torque

n [rpm]

=

Motor speed

t

r

[sec]

=

Stopping time

W [J]

=

Brake work

W

max

[J]

=

Maximum brake work for one

brake operations

Braking Frequency (Brakes/hr)

Braking W

ork (J)

Brake

Calculations