A4.4 pid computation details, A4.4.2 pid control parameters, A4.5 control output – Yokogawa Wireless Temperature Transmitter YTA510 User Manual

Page 80: A4.4, A4.4.2, A4.5, A4-4

A4-4

IM 01C50T02-01E

Index Parameter Name

Default

(factory setting)

Write

Valid Range

Description

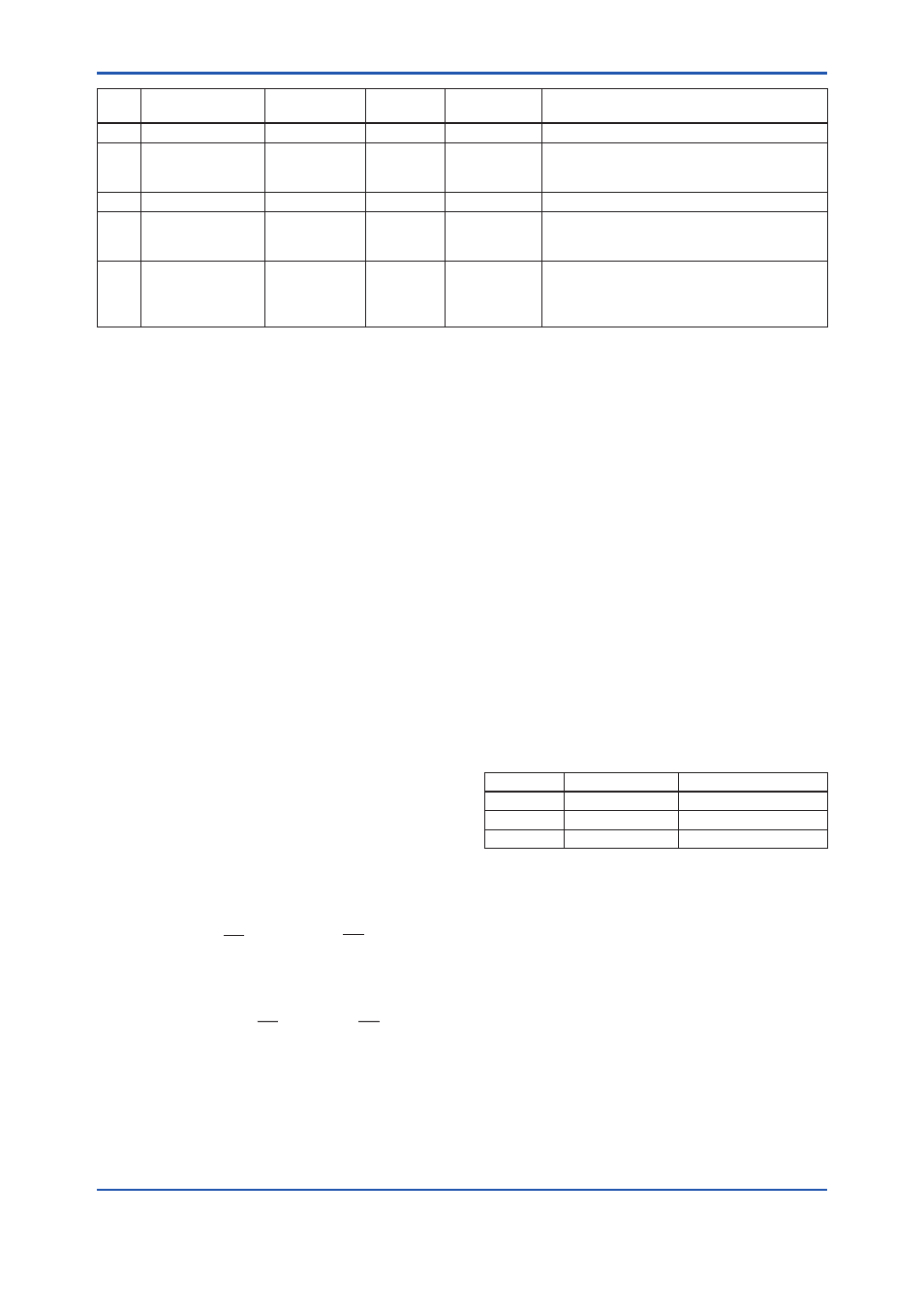

61

HI_ALM

—

—

As above

62

LO_ALM

—

—

As above

Reset when the PV value has increased

above [LO_LIM + ALM_HYS].

63

LO_LO_ALM

—

—

As above

64

DV_HI_ALM

—

—

Alarm that is generated when the value of [PV

- SP] has exceeded the DV_HI_LIM value.

Other features are the same as HI_HI_ALM.

65

DV_LO_ALM

—

—

Alarm that is generated when the value of [PV

- SP] has decreased below the DV_LO_LIM

value. Other features are the same as

LO_LO_ALM.

A4.4 PID Computation Details

A4.4.1 PV-proportional and -derivative

Type PID (I-PD) Control Algorithm

For PID control, the PID block in an YTA employs

the PV-proportional and PV-derivative type PID

control algorithm(referred to as the I-PD control

algorithm) in Auto and RCas mode. The I-PD

control algorithm ensures control stability against

sudden changes in the setpoint, such as when

the user enters a new setpoint value. At the

same time, the I-PD algorithm ensures excellent

controllability by performing proportional, integral,

and derivative control actions in response to

changes of characteristics in the controlled process,

changes in load, and occurrences of disturbances.

In Cas mode, PV derivative type PID control

algorithm (referred to as the PI-D control algorithm)

is employed in order to obtain better performance

against the changes in the setpoint. The algorithm

is automacially switched by the block according

to the mode. A basic form of each algorithm is

expressesd in the equation below.

I-PD Control Algorithm (in Auto / RCas mode)

∆MVn = K {∆PVn + (PVn − SPn) + ∆(∆PVn)}

∆T

Ti

Td

∆T

PI-D Control Algorithm (in Cas mode)

∆MVn = K{∆(PVn−SPn)+ (PVn−SPn)+ ∆(∆PVn)}

∆T

Ti

Td

∆T

Where,

∆MVn = change in control output

∆PVn = change in measured (controlled) value

= PVn - PVn-1

∆T

= control period = period_of_execution in

Block Header

K

= proportional gain = GAIN (= 100/

proportional band)

Ti

= integral time = RESET

Td

= derivative time = RATE

The subscripts, n and n-1, represent the time

of sampling such that PVn and PVn-1 denote

the PV value sampled most recently and the PV

value sampled at the preceding control period,

respectively.

A4.4.2 PID Control Parameters

The table below shows the PID control parameters.

Parameter

Description

Valid Range

GAIN

Proportional gain 0.05 to 20

RESET

Integral time

0.1 to 10,000 (seconds)

RATE

Derivative time

0 to infinity (seconds)

A4.5 Control Output

The final control output value, OUT, is computed

based on the change in control output ΔMVn, which

is calculated at each control period in accordance

with the aforementioned algorithm. The PID block

in a YTA performs the velocity type output action for

the control output.