A–83 – Micromod Micro-DCI: 53MC5000 Multi-Loop Process Controller FLEXIBLE CONTROL STRATEGIES User Manual

Page 173

A.1.10 CS41 - FOUR-LOOP CONTROLLER

The four-loop controller provides four independent PID controllers. Loading CS41 initializes the

ANI1–7 engineering spans to 100.0, and the display list is modified to the four-loop sequence. The

control scheme is shown in block diagram form in Figure A–10. Also provided is Table A-10, which

is a worksheet that shows the CS41 wirelist connections; wirelist datapoints not connected are left

at default. Table A-10 is partitioned by FCS module type applicable to CS41 (those modules in Fig-

ures 2-1 through 2-3). The datapoint parameters for each module are shown with their default val-

ues.

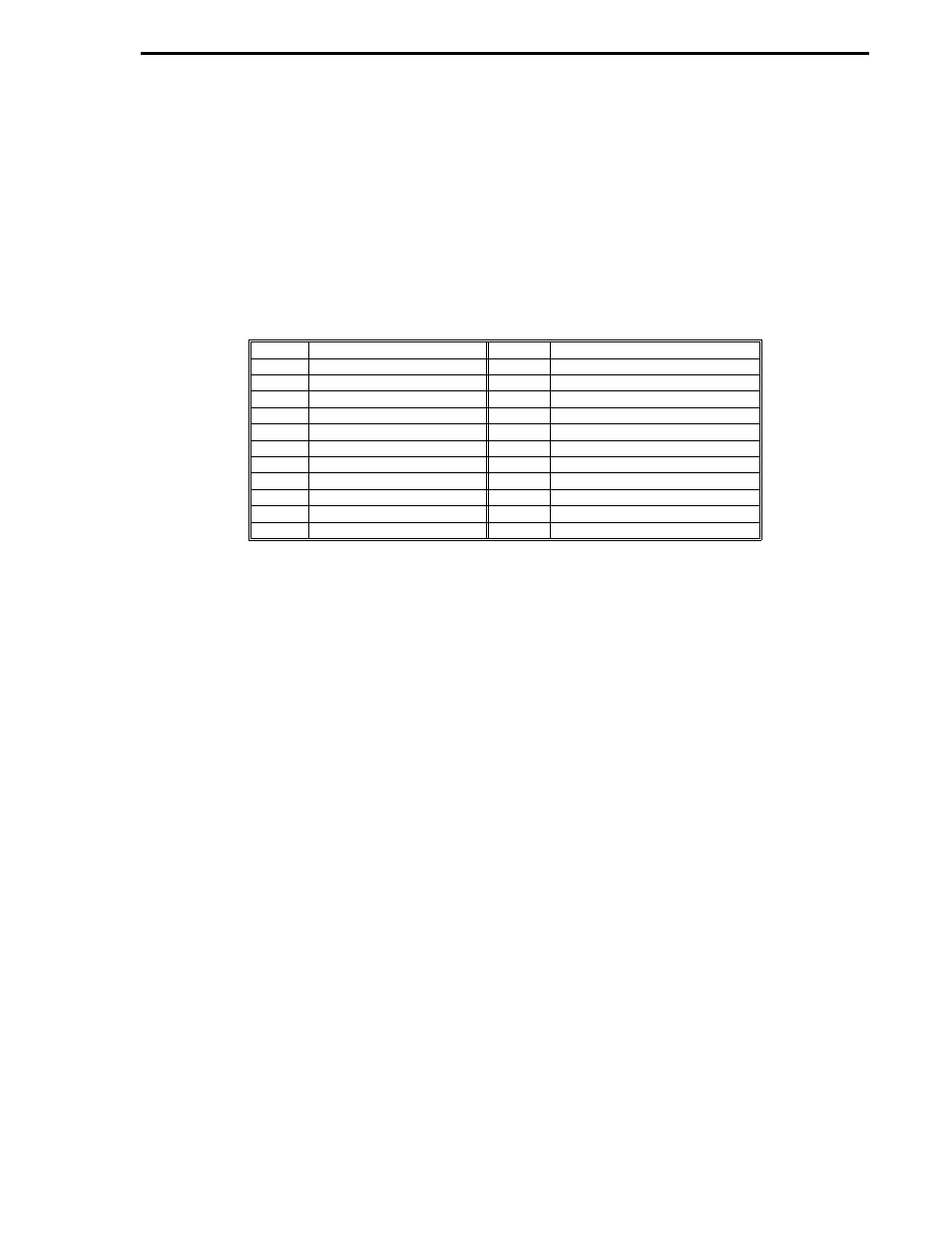

The following I/O assignments result from loading CS41:

ANI0

Process Variable Loop 1

CCI0

Remote Setpoint Enable Loop 1

ANI1

Process Variable Loop 2

CCI1

Remote Setpoint Enable Loop 2

ANI2

Remote Setpoint Loop 1

CCI2

Remote Setpoint Enable Loop 3

ANI3

Remote Setpoint Loop 2

CCI3

Remote Setpoint Enable Loop 4

ANI4

Process Variable Loop 3

CCI4

Force Fallback Loop 1

ANI5

Process Variable Loop 4

CCI5

Force Fallback Loop 2

ANI6

Remote Setpoint Loop 3

CCI6

Force Fallback Loop 3

ANI7

Remote Setpoint Loop 4

CCI7

Force Fallback Loop 4

ANO0

ControlOutput Loop 1

CCO0

Process Alarms Loop 1

ANO1

ControlOutput Loop 2

CCO1

Process Alarms Loop 2

ANO2

ControlOutput Loop 3

CCO2

Process Alarms Loop 3

ANO3

ControlOutput Loop 4

CCO3

Process Alarms Loop 4

Each loop contains an individual set of parameters that dictates its operation. This allows the loops

to be fully independent. The description that follows is for Loop 1, with Loops 2, 3, and 4 refer-

enced parenthetically.

The input/output configuration for all loops is the same: process variable, remote setpoint, remote

setpoint enable, control output, force fallback, and process alarms. Only the process variable and

control output signals are essential for standard loop control purposes; the other signals do not

have to be configured. Process variable ANI0 (ANI1, ANI4, ANI5) is the controlled parameter, and

control output ANO0 (ANO1, ANO2, ANO3) is the regulator signal. When a closed contact is pre-

sent on CCI0 (CCI1, CCI2, CCI3), remote setpoint selection is possible using the R/L push buttons.

When an open contact is present on CC14 (CC15, CC16, CC17), the output and setpoint are

forced to fallback values contained in the OTV and STV parameters of the CON modules when the

applicable enabling parameters are set. While remote setpoint is selected, the control setpoint

value is obtained from ANI2 (ANI3, ANI6, ANI7). Whenever an alarm condition associated with the

control loop occurs, the contact CCO0 (CCO1, CCO2, CCO3) is closed; otherwise, the contact is

open.

Appendix A. Control Strategy Wirelists

4110-TXT

A–83