A.1.7 cs21 - two-loop cascade controller – Micromod Micro-DCI: 53MC5000 Multi-Loop Process Controller FLEXIBLE CONTROL STRATEGIES User Manual

Page 142

A.1.7 CS21 - TWO-LOOP CASCADE CONTROLLER

The two-loop cascade controller consists of two standard PID control loops, arranged in a cascade

setup whereby the output of the primary controller, based on its setpoint and process variable, be-

comes the setpoint for the secondary controller.

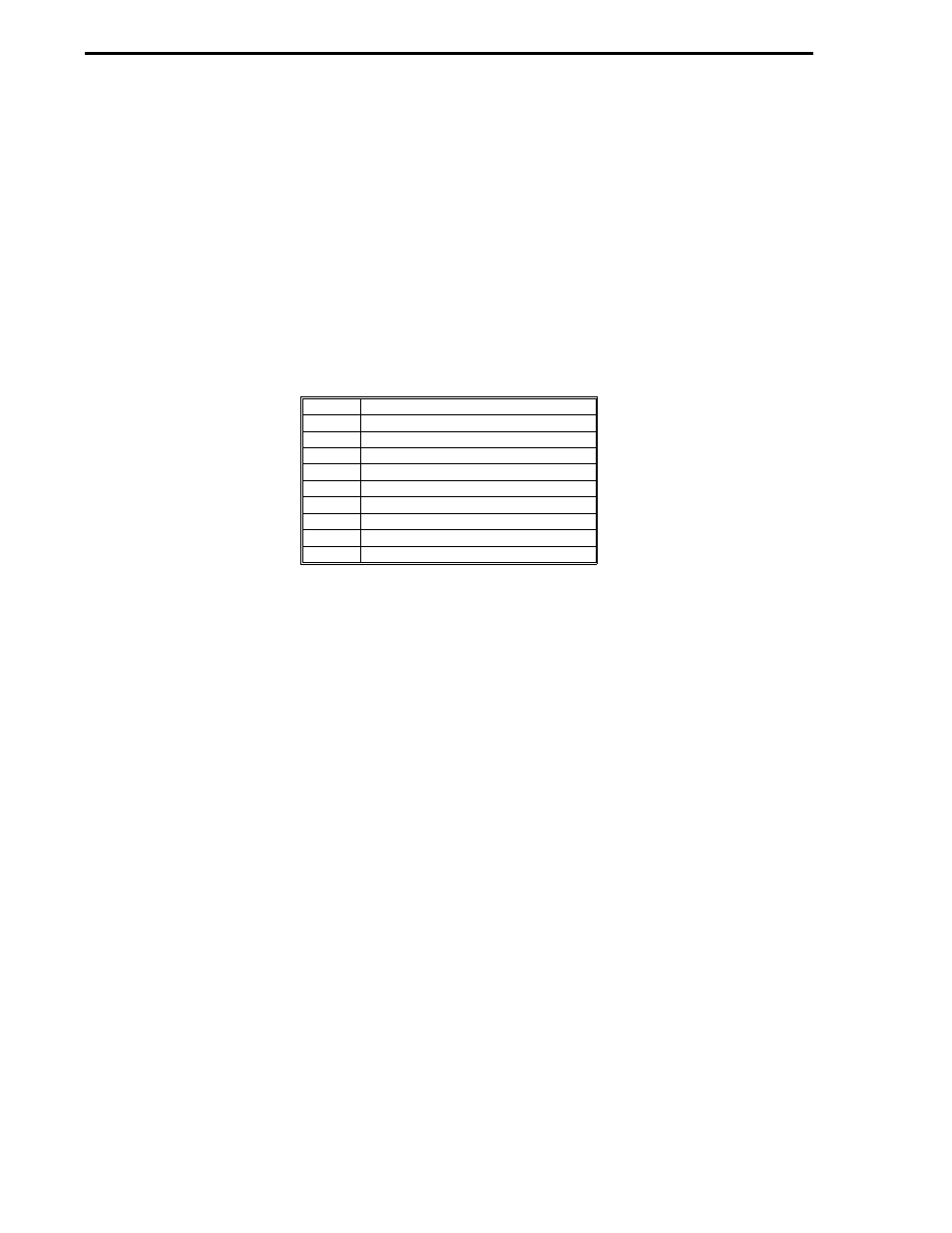

Loading CS21 initializes the ANI2 engineering span to 100.0, C088 to 1.0, C089 to 1.0, and the dis-

play list sequence to incorporate a second display group (CON1). The control scheme is shown in

block diagram form in Figure A-7. Also provided is Table A-7, which is a worksheet that shows the

CS20 wirelist connections; wirelist datapoints not connected are left at default. Table A-7 is parti-

tioned by FCS module type applicable to CS21 (those modules illustrated in Figures 2-1 and 2-2).

The datapoint parameters for each module are shown with their default values.

The following I/O assignments result from loading CS21:

ANI0

Process Variable Primary

ANI1

Remote Setpoint Primary

ANI2

Process Variable Secondary

ANI3

Additive Feed Forward Secondary

ANO0

Control Output (Secondary)

ANO1

Secondary Setpoint Transmit

CCI0

Cascade Enable

CCI1

Remote Enable Primary

CCO0

Process Alarms Secondary

CCO1

Process Alarms Primary

This control strategy provides bumpless/balanceless transfer between local and cascade control by

forcing the primary output to match the secondary setpoint when the secondary is in local mode.

Proper scaling of the primary output (secondary setpoint) is accomplished using the K1 (C149) and

B1 (C148) parameters of the secondary controller. The current setpoint of the secondary, also

scaled by the same K1 and B1, is reflected in the value of ANO1.

ANI2 is the controlled process variable of the secondary that the output (ANO0) is controlling

through the final element. The secondary also is provided with an additive feed forward signal

(ANI3). Cascade control is not permitted if CCI0 is an open contact. The primary process variable

is supplied by ANI0. If a closed contact is on CCI1, selection of remote setpoint operation is possi-

ble in the primary controller via the R/L push button. The remote setpoint value is derived from

ANI1.

Alarm conditions for both primary and secondary controllers are indicated by a closed contact on

the CCOs. Secondary loop alarms appear at CCO0, and primary loop alarms appear at CCO1.

FCS 53MC5000 Flexible Control Strategies

A–52

417-TXT