Datamax-O'Neil Class Series II Programmer’s Manual User Manual

Page 85

Extended System-Level Command Functions

Class Series 2 Programmer’s Manual

71

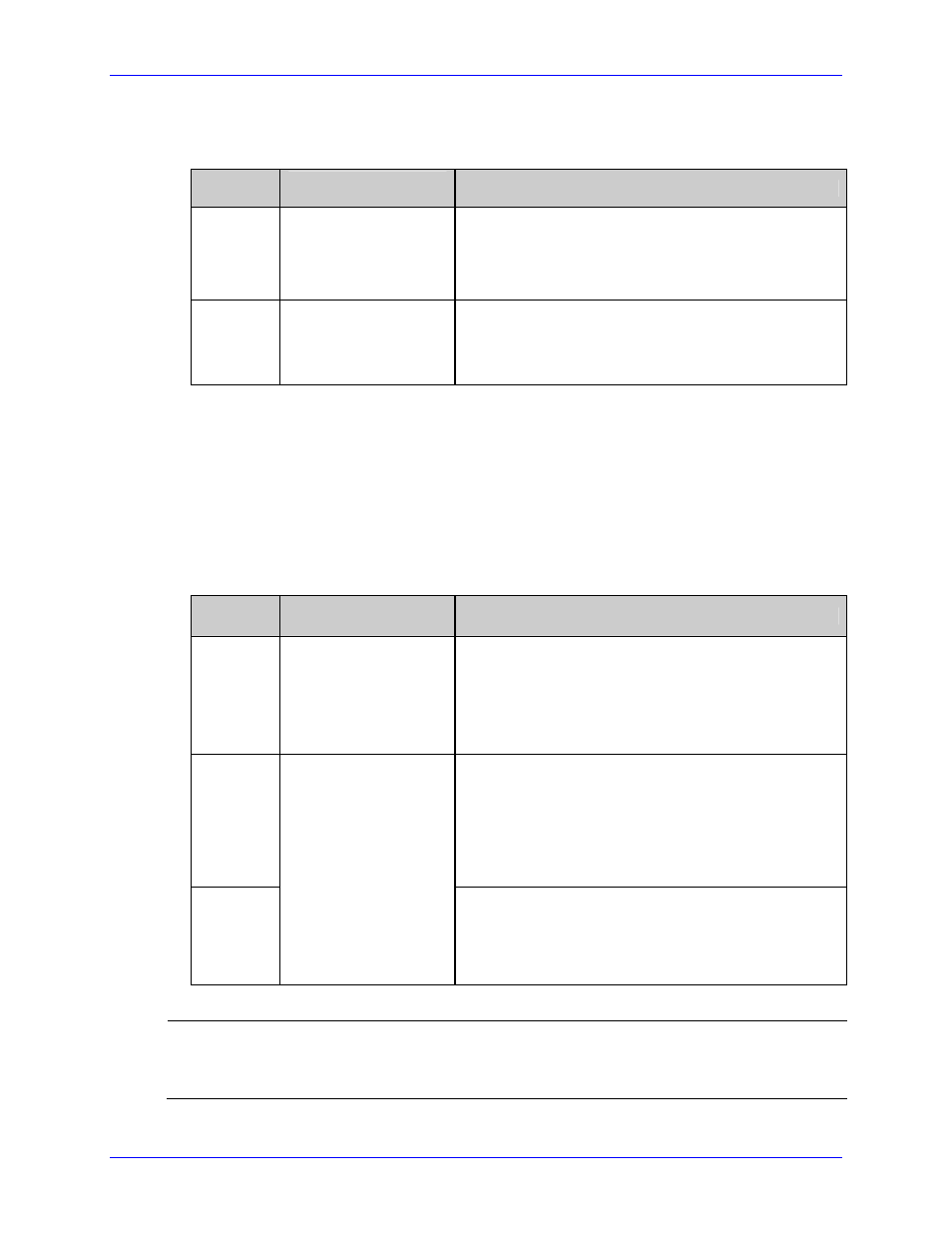

(IL) Imaging Mode – This command instructs the printer whether to pre-image the

label format:

Value

Units /

Interpretation

Imaging Mode Definition

M

Multiple Label

The printer images multiple labels as memory

permits, achieving the fastest throughput; however,

if time-stamping, the time will reflect the moment

the label is imaged rather than when actually

printed.

S

Single Label

The printer images the next label only after the

previous label has been successfully printed. Single

processing provides time-stamps that are more

accurate, but it slows label throughput time.

(IM) Internal Module – This command sets the number of 1K blocks (or 4K blocks

for Non-Display models; see the

(LA) Label Alignment – This command prevents labels with lengths that are less

than the distance between the print head and the Media Sensor from being wasted at

power-up. See the appropriate Operator’s Manual for specific information. Unless

otherwise noted, the following information pertains to all Non-Display models:

Value &

Mode

Media Type

Description / Operation

N =

Disabled

6.5-inch and greater

(≥ 16.51 cm) die-cut,

notched, reflective,

continuous, and

multiple form lengths.

When disabled, Non-Display models begin printing

at the current location, unless equipped with RTC

(Real Time Clock); see note below. The EX2

assumes the label position has not moved while

power was “Off” and that no system changes have

occurred.

A =

Auto

6.5-inch or less

(≤16.51 cm)

die-cut, notched, and

reflective

In auto mode, the printer will verify the label

position using the provided Alignment Length

before printing the first label after power-up. Press

and hold the FEED Key four seconds so the printer

will measure the length of the label. The EX2 will

only measure the label length when new label stock

is loaded.

Y =

Enabled

When enabled, the printer will verify the label

position using the provided Alignment Length

before printing the first label after power-up.

Specify the Label Alignment Length using the

command, or the Setup Menu.

Table 5-3: Label Alignment Command

The Real Time Clock (RTC) option allows the position-state of the label to be stored,

thus eliminating the need for an alignment prior to first label printing (assuming the

label has not moved during power off). If the stock has been changed then a Forced

Alignment (press and hold FEED 4 seconds) is recommended.