Datamax-O'Neil Class Series II Programmer’s Manual User Manual

Page 83

Extended System-Level Command Functions

Class Series 2 Programmer’s Manual

69

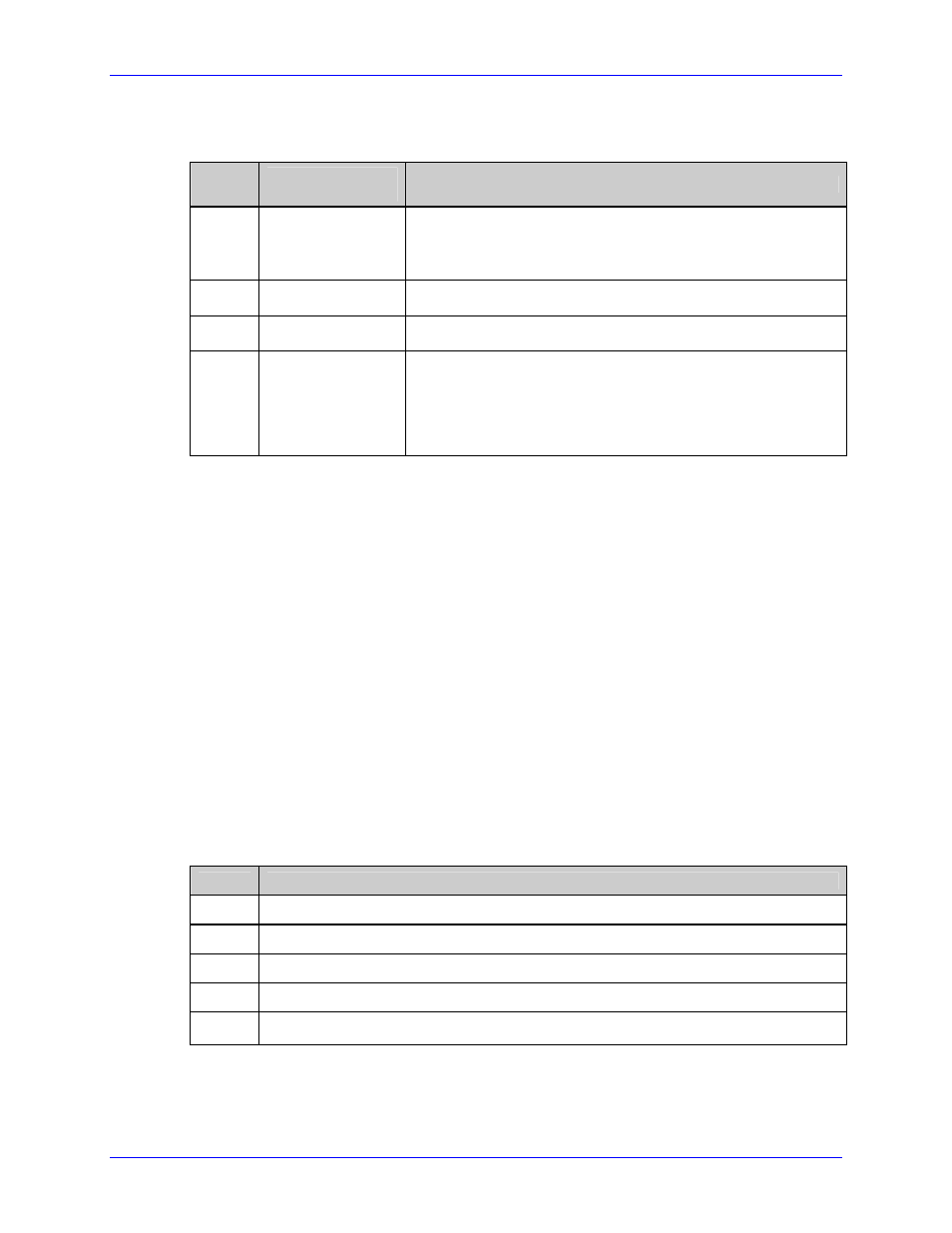

(GE) GPIO Equipped – This command is used to interface the printer to external

controlling devices (see Appendix J):

Value

Units /

Interpretation

GPIO Enable Definition

A

Applicator

Enables the standard applicator mode, de-asserting DRDY

as soon as last label starts printing, allowing FEED any

time, and not de-asserting DRDY when PAUSED.

N

Disabled

Disables the GPIO Port.

V

Verifier

Enables the GPIO Port for a bar code verifier.

2

Applicator2

Enables the alternate applicator mode, where Data Ready

(DRDY) is extended to overlap the End Of Print (EOP) signal

by about 1 msec when printing the last label; and, where

PAUSE or FAULT de-asserts the DRDY signal and inhibits

the FEED operation.

(GL) Gap Sensor Location

(MP Compact4 Mark II only)

– This command will tell the

printer which sensor to use when GAP mode is selected either by the

or by

the media, (Outer is default). Inner Gap sensor is defined as the sensor 17.2mm

from the edge of the media

(GM) Gap / Mark Value – This command sets threshold value for the media

sensor’s “gap” or “mark” parameter.

(GP) GPIO Error Pause – This command enables or disables the printer from

sending a service required fault to the GPIO output (Applicator Interface CCA, Type 2

only).

(GR) Gain Reflective Value – This command sets the sensitivity of the reflective

media sensor.

(GS) GPIO Slew – This command sets the GPIO slew function and control:

Value

Slew Interpretation

0

Standard (Active Low)

1

Low Pulse *

2

High Pulse *

3

Slews while low (Active Low)

4

Slews while high (Active High)

* Pulse must be at least 60 milliseconds in length; functions as if pressing the Feed Key,

clearing alarms and advancing media.