MITSUBISHI ELECTRIC P500YMF-C User Manual

Page 8

–6–

[3] Brazing

No changes from the conventional method, but special care is required so that foreign matter (ie. oxide scale, water, dirt,

etc.) does not enter the refrigerant circuit.

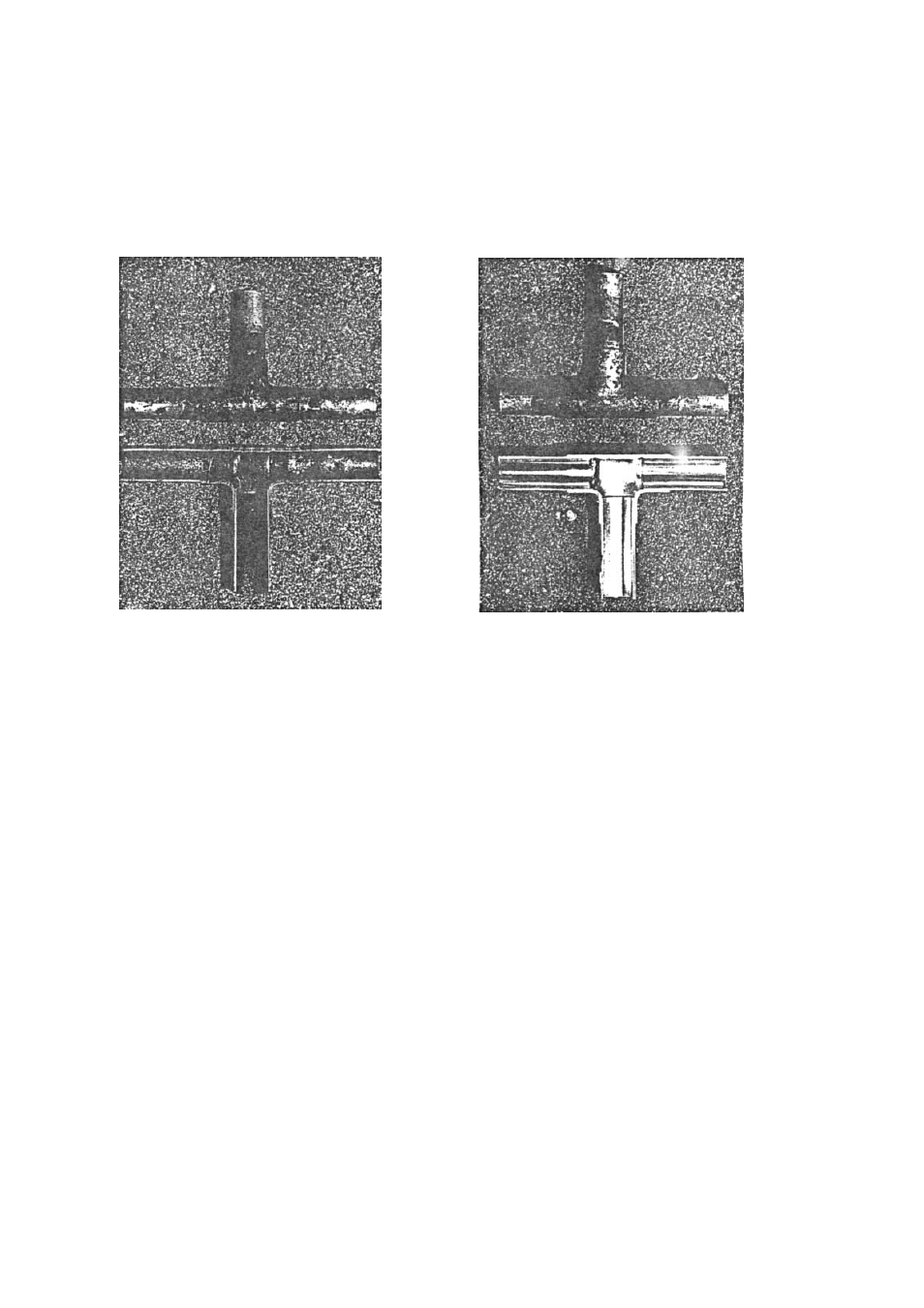

Example : Inner state of brazed section

When non-oxide brazing was not used

When non-oxide brazing was used

Items to be strictly observed :

1. Do not conduct refrigerant piping work outdoors on a rainy day.

2. Apply non-oxide brazing.

3. Use a brazing material (Bcup-3) which requires no flux when brazing between copper pipes or between a copper pipe

and copper coupling.

4. If installed refrigerant pipes are not immediately connected to the equipment, then braze and seal both ends of them.

Reasons :

1. The new refrigerant oil is 10 times more hygroscopic than the conventional oil. The probability of a machine failure if

water infiltrates is higher than with conventional refrigerant oil.

2. A flux generally contains chlorine. A residual flux in the refrigerant circuit may generate sludge.

Note :

•

Commercially available antioxidants may have adverse effects on the equipment due to its residue, etc. When

applying non-oxide brazing, use oxygen free nitrogen (OFN).