MITSUBISHI ELECTRIC P500YMF-C User Manual

Page 47

–45–

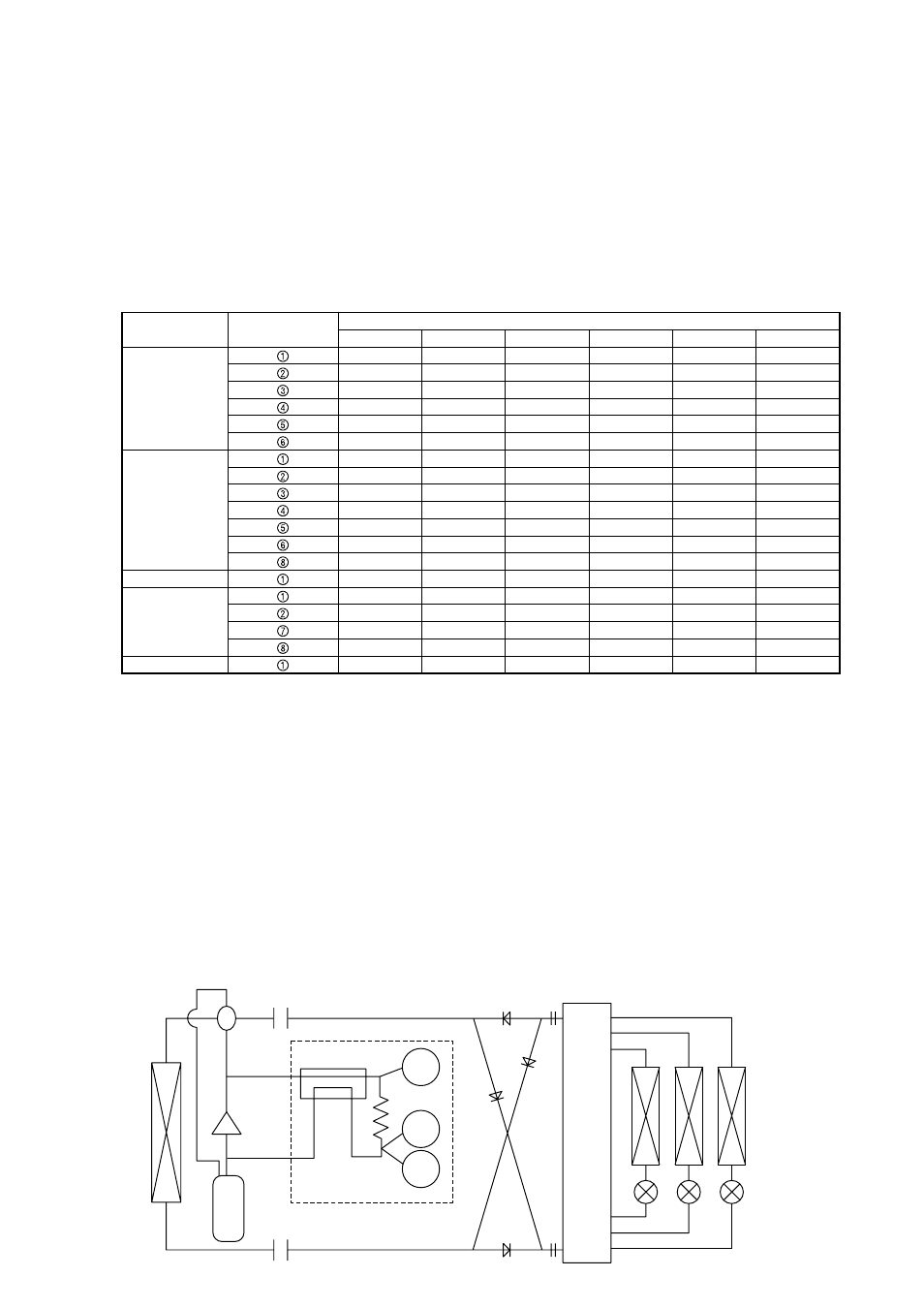

TH9

Four-way valve

Compressor

Accumulator

CS circuit

Separ

ate compressor

TH2

LPS

Heat exchanger

Outdoor heat e

xchanger

Indoor heat

e

xchanger

Flo

w control

valv

e

Operation mode

Full cooling

Cooling mainly

Full heating

Heating mainly

Defrosting

ON

ON

OFF

OFF

OFF

OFF

ON

ON

OFF

OFF

OFF

OFF

OFF

ON

ON

ON

ON

OFF

ON

ON

ON

ON

ON

OFF

OFF

ON

ON

ON

ON

OFF

OFF

OFF

ON

ON

ON

ON

OFF

ON

ON

ON

ON

OFF

ON

OFF

ON

ON

ON

OFF

ON

OFF

OFF

ON

ON

ON

ON

OFF

ON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

ON

OFF

OFF

OFF

ON

ON

OFF

ON

OFF

OFF

OFF

OFF

OFF

ON

OFF

OFF

OFF

OFF

OFF

OFF

ON

ON

OFF

OFF

OFF

ON

ON

OFF

OFF

OFF

OFF

OFF

ON

OFF

OFF

OFF

OFF

OFF

OFF

ON

ON

OFF

OFF

OFF

ON

Operation pattern

SV3

SV4

SV5

SV6

SV7

SV8

Solenoid valve

* In stop, all are OFF.

(9)

Outdoor unit heat exchanger capacity control

1) Control method

•

In order to stabilize the evaporation temperature during cooling and the high-pressure pressure during heating that

are required in response to performance needs, the capacity of the outdoor heat exchanger is controlled by regulat-

ing the fan volume of the outdoor unit by phase control and controlling the number of fans and by using the solenoid

valves to vary the number of out door heat exchangers being used.

2) Control

•

When both of the compressors are stopped, the fans for the outdoor units are also stopped.

•

The fans operate at full speed for 5 seconds after starting.

•

The fans for the outdoor unit are stopped during defrosting.

3) Capacity control pattern

(10) Circulating composition sensor (CS circuit)

• As shown in the drawing below; the CS circuit has the structure to bypass part of the gas discharged from the compres-

sor through the capillary tube to the suction side of the compressor, exchange heat before and after the capillary tube,

and produce two phase (gaseous and liquid) refrigerant at the capillary tube outlet. The dryness fraction of refrigerant at

the capillary tube outlet is estimated from the temperature of high pressure liquid refrigerant at the capillary tube inlet

(TH9) and the temperature of low pressure two phase (gaseous and liquid) refrigerant at the capillary outlet (TH2) and

the pressure (LPS) to calculate the composition of refrigerant circulating the refrigeration cycle (

α

OC). It is found by

utilizing the characteristic that the temperature of two phase (gaseous and liquid) R407C under a specified pressure

changes according to the composition and dryness fraction (gas-liquid ratio in weight).

• The condensing temperature (Tc) and the evaporating temperature (Te) are calculated from

α

OC, high pressure

(HPS), and low pressure (LPS).

• The compressor frequency, the outdoor fan, and others are controlled according to the codensing temperature (Tc)

and the evaporating temperature (Te).

• CS circuit configuration (Outline drawing)