Cascade control, Cascade control -15, Pid m – IDEC MicroSmart Pentra User Manual

Page 38

PID M

ODULE

M

AIN

F

UNCTIONS

FC5A MicroSmart PID Module User’s Manual FC9Y-B1283

4-15

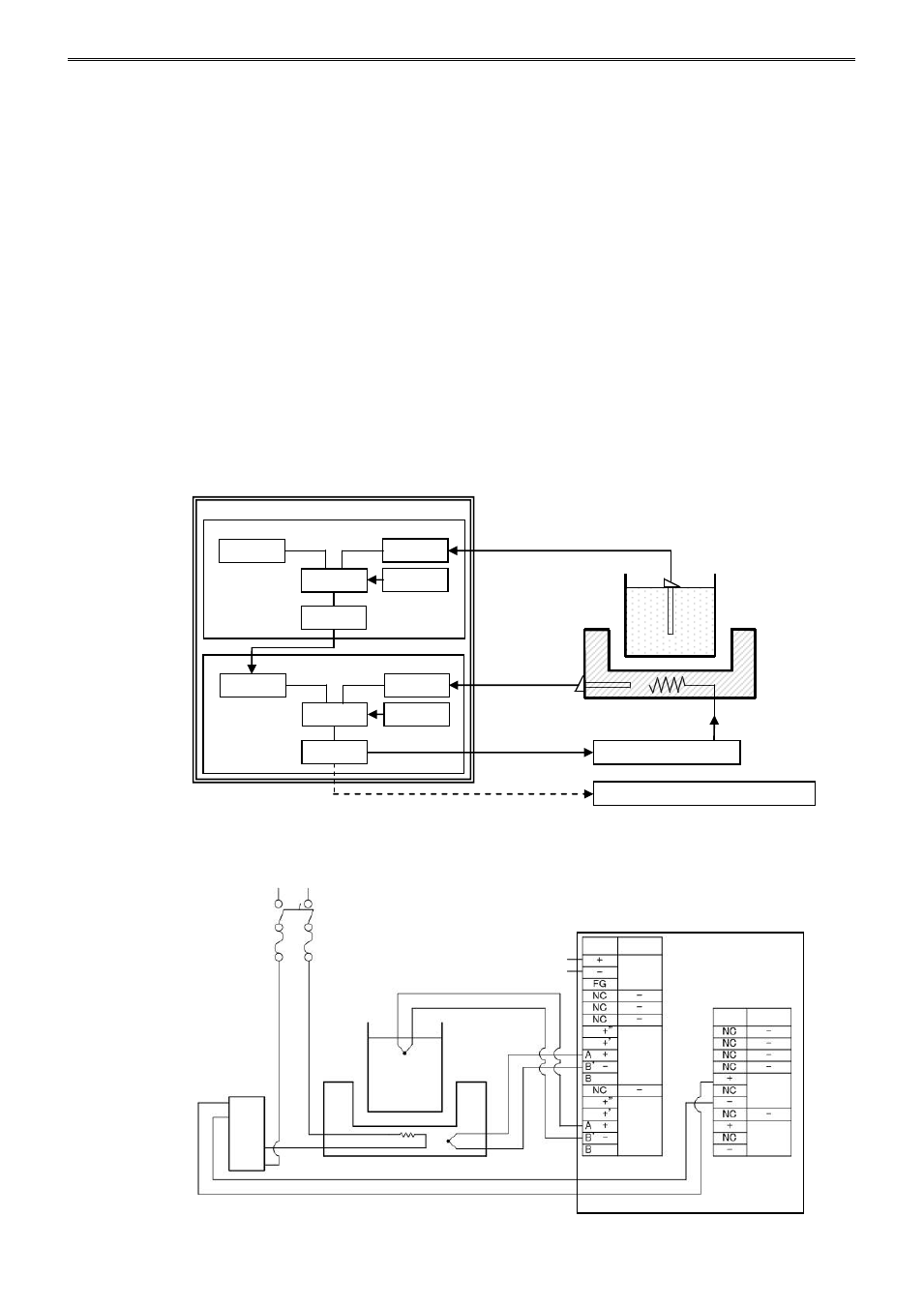

Cascade Control

The cascade control combines two PID controls to form one feedback loop to control a single target. The

cascade control is effective for applications in which the delay time or dead time is considerably large. When

delay time is large, it takes a long time for the process variable (PV) to change after the output manipulated

variable (MV) is changed. By using the cascade control, highly stable control can be realized for such

applications, though it takes time for the process variable (PV) to reach the set point (SP).

CH1 control is used as the master and CH0 control as the slave of the cascade control. The output

manipulated variable (MV) of the master (CH1 control) becomes the set point (SP) of the slave (CH0 control),

and the control result of CH0 is outputted from the CH0 output. The output manipulated variable (MV) (0 to

100%) of the master (CH1 control) is corresponded to the set point (SP) of the slave (CH0) according to the

external SP input linear conversion minimum and maximum values. For example, when the external SP input

linear conversion minimum value is 100°C and the maximum value is 400°C, the output manipulated variable

(MV) (0 to 100%) of the master (CH1 control) is converted as follows: 0% is converted to 100°C, 50% is

converted to 250°C, and 100% is converted to 400°C.

When a system using the cascade control is designed, it is required that the slave (CH0 control) have smaller

delay time and faster response comparing to the master (CH1 control).

Example: The cascade control is used for an application in which the heat quantity of a heater is controlled

using a power controller in order to control the temperature of the control target as shown in the figure below.

It is also possible to utilize the heating/cooling control to prevent a rapid temperature rise of the control target

by using a fan as the cooling output.

System Configuration and Wiring

Wiring Example of the FC5A-F2M2 [Current Output Type]

PV (M)

SP (M)

PID (M)

MV (M)

AT (M)

PV (S)

SP (S)

PID (S)

MV (S)

AT (S)

Master (Primary Control)

Slave (Secondary Control)

PID Module (with Cascade Control)

Power Controller

Control Target

Heater

CH1 Input

CH0 Input

CH0 Output

Cooling Equipment such as Fan

CH1 Output

Single Phase

200V

Control

Target

CH0 Thermocouple

CH1 Thermocouple

+

-

+

-

Power Controller

Heater

u

U

+

-

Power

Supply

PID Module (FC5A-F2M2)

IN0

IN1

24V DC

OUT0

OUT1

Channel

Terminal

No.

Terminal

No.

Channel