Pid m – IDEC MicroSmart Pentra User Manual

Page 28

PID M

ODULE

M

AIN

F

UNCTIONS

FC5A MicroSmart PID Module User’s Manual FC9Y-B1283

4-5

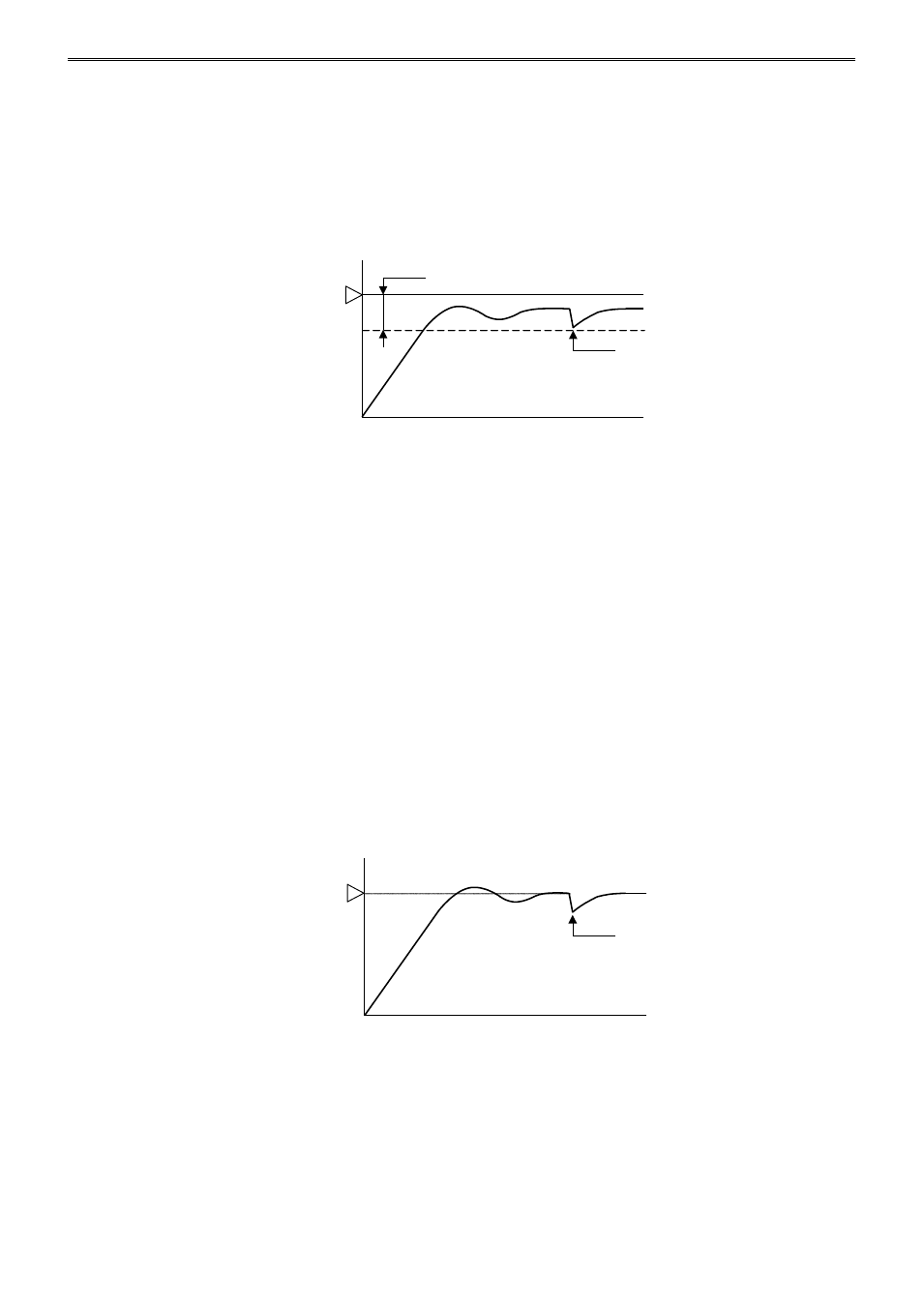

PD Control Action (Proportional + Derivative Action)

Compared with P action, the response to rapid temperature change due to disturbance is faster, the

temperature control can be stabilized in a shorter time, and transitional response characteristic can be

improved in PD control action. PD control action is suitable for the processes in which the temperature

rapidly changes.

If the integral time of the PID module parameter is set to 0, the control action becomes the PD control

action.

• If the derivative time is shortened, the derivative action becomes weak. The response to the rapid

temperature change becomes slower. Because the action to suppress the rapid temperature rises

becomes weaker, the time for the process variable (PV) to reach the set point (SP) is shortened;

however, overshoot can occur.

• If the derivative time is extended, the derivative action becomes strong. The response to the rapid

temperature change becomes faster. Because the action to suppress the rapid temperature rises

becomes strong, the time for the process variable (PV) to reach the set point (SP) is extended; however,

overshoot can be decreased.

The offset caused by the PD control action can be corrected by configuring the reset value. The reset

value can be automatically calculated by the auto-reset function.

PID Control Action (Proportional + Integral + Derivative Action)

P action suppresses the overshoot and the hunting, I action corrects the offset, and D action corrects

rapid temperature change due to disturbance in shorter time. Thus, using PID control action, optimal

temperature control can be performed. The proportional band, integral time, derivative time, and ARW

can be automatically calculated by the auto-tuning (AT).

Set Point (SP)

Temperature

Time

Proportional Band

Disturbance

Set Point (SP)

Temperature

Time

Disturbance