IDEC MicroSmart Pentra User Manual

Page 149

A

PPENDIX

9-2

FC5A MicroSmart PID Module User’s Manual FC9Y-B1283

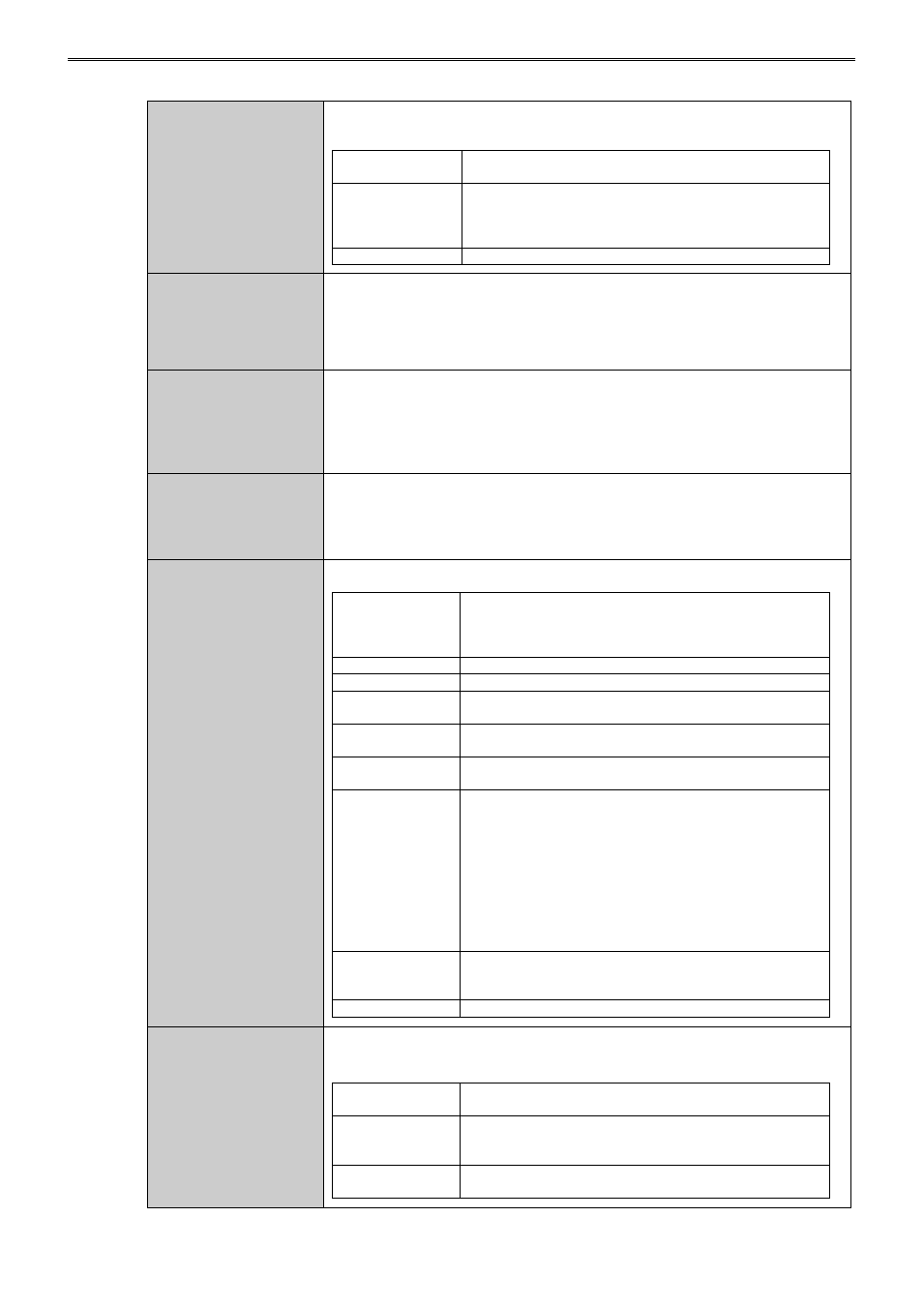

Loop Break Alarm

A trouble of the actuator, such as heater break or heater adhesion, can be detected

as the loop break alarm.

For details about the loop break alarm, see page 6-39.

Loop break alarm

time

0 to 200 minutes

Loop break alarm

span

When input is thermocouple or resistance thermometer:

0 to 150°C (°F) or 0.0 to 150.0°C (°F)

When input is voltage/current:

0 to 1500

Output

Bit 2 of the operating status

Set Point (SP) Ramp

Function

When the set point (SP) is changed, the set point (SP) is gradually increased from the

original set point (SP) to the new set point (SP) according to the configured

rate-of-change (°C/minute, °F/minute).

When the control is started, the set point (SP) is increased from the current process

variable (PV) to the configured set point (SP) according to the configured

rate-of-change (°C/minute, °F/minute).

Auto/Manual Mode

Switching

Auto or manual mode can be switched.

When the control mode is switched from auto to manual mode and vice versa, the

balanceless-bumpless function works to prevent a sudden change in output

manipulated variable (MV).

When the power is turned on, the operation parameters in Block 1 are retained, so

the control action starts with the previous mode at the time of power off.

Cascade Control

The cascade control is an advanced control that uses 2 inputs [CH1 as a master

(primary control) and CH0 as a slave (secondary control)] to control one process.

The output manipulated variable (MV) calculated according to the process variable

(PV) and the set point (SP) of the master (CH1) is used as the set point (SP) of the

slave (CH0) for control. The control results will be outputted from the output CH0.

Heating/Cooling

Control

Output (CH0 only)

When it is difficult to control the target process with heating control only, cooling

control can be added to perform the heating/cooling control.

Cooling

proportional band

0.0 to 10.0 times. Cooling proportional band is the

product of this value and the heating proportional band.

The cooling control becomes ON/OFF control when the

cooling proportional band is 0.

Integral time (I)

0 to 10000 seconds

Derivative time (D) 0 to 10000 seconds

Cooling control

period

1 to 120 sec

Overlap/Dead

band

When input is thermocouple/RTD: -200.0 to 200.0°C (°F)

When input is voltage/current: -2000 to 2000

Cooling output

ON/OFF hysteresis

When input is thermocouple/RTD: 0.1 to 100.0°C (°F)

When input is voltage/current input: 1 to 1000

Cooling output

manipulated

variable (MV)

upper limit,

lower limit

When output type is voltage:

Upper limit: Cooling output manipulated variable lower

limit to 100%

Lower limit: 0% to cooling output manipulated variable

upper limit

When output type is current:

Upper limit: Cooling output manipulated variable lower

limit to 105%

Lower limit: -5% to cooling output manipulated variable

upper limit

Cooling method

Air cooling (Linear characteristic),

Oil cooling (1.5th power of the linear characteristic), or

Water cooling (2nd power of the linear characteristic)

Cooling output

CH1 output.

External SP Input

The input value of input CH1 is used as the set point (SP) of CH0 control.

When the external SP input bias is configured, it is added to the set point (SP) of

CH0 control. The input types that can be selected are shown in the following table.

Input type

Current: 4 to 20mA or 0 to 20mA

Voltage: 1 to 5V or 0 to 1V

Allowable input

Current: 50mA DC maximum

Voltage (0 to 1V): 5V DC maximum

Voltage (1 to 5V): 10V DC maximum

Input impedance

Current: 50Ω

Voltage: 100kΩ